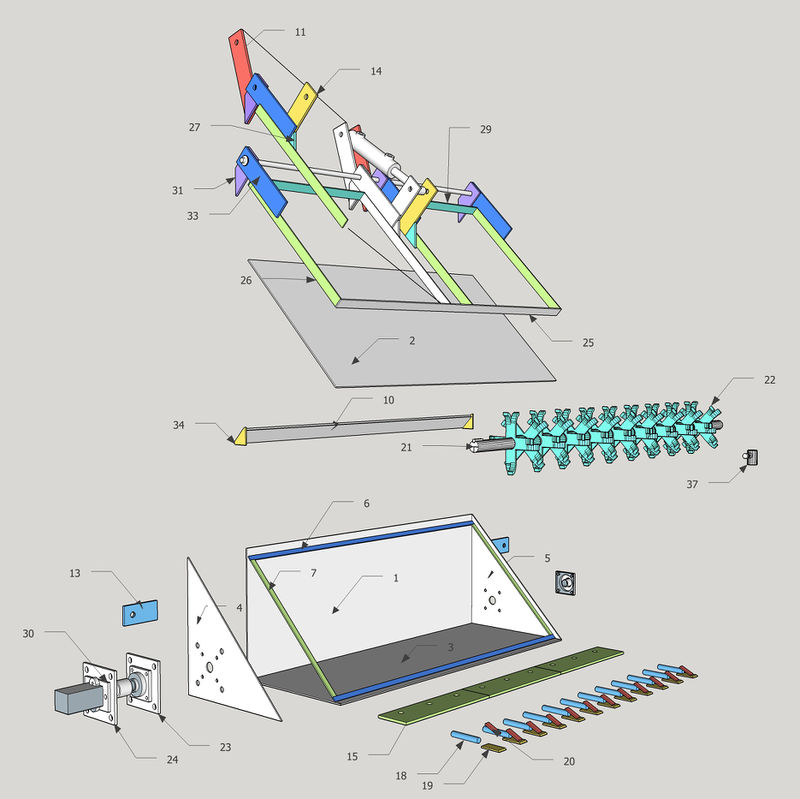

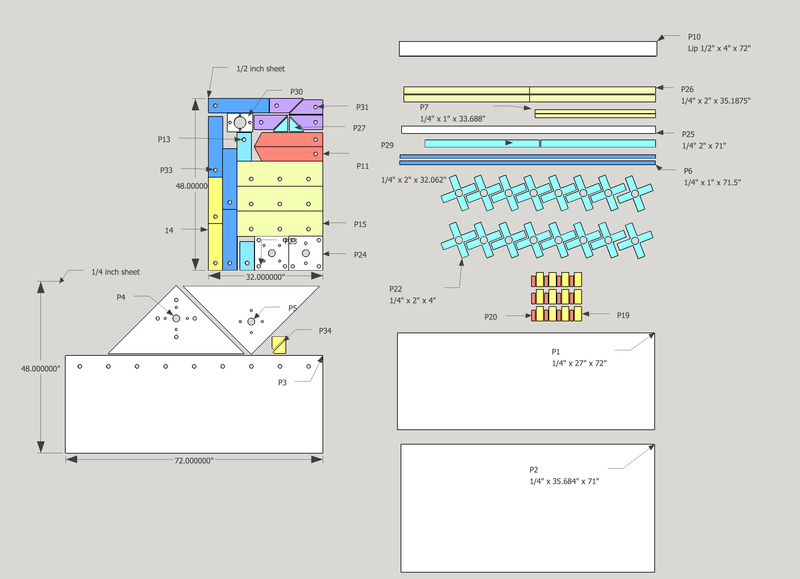

Soil Mixer - Overall Machine - Build Instructions

cut the shaft from stock

- Cut the shaft from the 1 7/8" stock, 81.5".

Preparing the Bucket

Dev: it would make more sense to use the smaller lighter eaier to handle plates to position the big plates, than vice versa. That back plate is very heavy and harder to hold square and aligned than the side walls. Secondly the back plate provides no help against the coontracdtion of the welds, whereas the side plates to help against the tilting from square of the back plate along one direction of rotation at least.

- Take P3 (Part 3) Bottom Sheet for bucket and lay flat.

- Mount bearings and p23 with 1" bolts loosely on the side plates P5 and P4.

- Tack weld backplate (P1) using a set square at a 90 degree angle on top of P3, don't finish the weld. Tack sidewall P4 into place at 90 degrees.

- Hold sidewall (P5) into place, and then stick Shaft 21 through the bearings to ensure proper alignment of side walls. Tack sidewall (P4). Now tighten the bolts. dev: it is not time to add the rotor yet because the tines are not ready to put on, and using it for alignment is not really needed here. There is little that could cause enough misalignment to be a problem anyway, too. The axis has a lot of play anyway. Still it would be a big deal if it was misaligned somehow, like wrong plate orientation, and would be better to fix now, true. but folding together the final insertion of the rotor shaft with the bucket assmebly was an improvement over this.

- Finish welding the seams for the back plate, bottom sheet and sidewalls (P1, P3, P4, P5). Using some bolts or the threaded rods and p23 to ensure alignment of the nuts, weld in the 1" nuts on the inside side of the sidewalls, on p4. These are used with some threaded rods and tubes to hold p24 on, see Drive section.

- Tack P7 into place with a gap of 1" on both ends from the bottom sheet and back plate. This distance is important for the two P6 parts to be welded in next. There should also be a 1" depth in from the top edge of the sidewall. Put in both 6's and tack. Tack in the second 7.

dev: it makes more sense to add the lower strip first, eliminating the need to measure the 1" gaps along a diagonal, and the possibility of error in that process.

- Check for fit with the lid plate p2

- finish the welds on the seal.

- Grind out the extra material around the welds on seams P6-P7 on the seal so the lid will sit flush on top.

Tine Fabrication Process

Note: the tine modules explosion is not shown in the overall diagram yet.

- Cut the 3" pipe sections with a cold cut saw

- Cut the tines from the 1/4x2" stock, 4" each, using the ironworker. 72 of them.

- Lay the tines out on the ground with the corners touching, and tack weld them together.

- Put the 3" pipe section in a vice and place the tines in position around it, then tack them together.

- cut the hole in the side of the pipe for the bolt to pass through with an oxy acetylene torch.

- Thread the bolt onto the nut such that the bolt extents 1/4" or so past the end of the nut

- Complete all welds while the tine module is in the vice.

- Remember there are 2 different tine module varieties, 9 of each type, the only difference being the radial position of the nut and associated hole in the side of the pipe. The bolt ends all tighten against the same flat surface, so to prevent all 18 from being in a line, they are not all identical. This is shown in the diagram. 9 are rotated 45 degrees relative to the other 9.

- Cut a slit 1.5 inches down the center of each tine.

- Bend the tips of the tines with a monkey wrench by hand to produce the curved tips.

- Repeat for all 9 tine modules of one type, then the other 9. Process cutting and welding of some parts in batches where suitable. I recommend going through the process of 1 module first, before doing batches, though.

Main rotor shaft

Bug note: There is no key used on the shaft in this design. Only the 1/2" by 4" bolt passed through the coupler and shaft.

- Remove the shaft from the bucket bearings.

- Grind out a flat 1/4" deep on the shaft P21 in the section for the bolts in the tine modules to tighten against, from the stock cut previously.

- Place the 6 spline coupler on the shaft, and use it as a guide to guide your drill bit. Start drilling the hole radially through the shaft for the bolt, starting from the flattened side of the shaft. After the hole is started, remove the coupler and continue, to avoid damaging the coupler.

- Pass the shaft P21 through one bearing, with the drilled bolt hole on the right end. Place the tine modules onto the shaft as it is being passed through.

- The bolts on the tine modules can be tightened at the very end of the whole module fabrication. I suggest not doing it now as the shaft may need to be removed for some reason later.

Motor quick attach plate

- Place the 2x1/2" threaded rods into the holes of P30. Tack in place. Check for fit with the motor, optionally. Finish the weld.

- Grind the flat side, the far side from where the motor is placed, flat, so the assembly can fit flush against a flat plate.

- Bolt P30 onto P24, and the motor onto this quick attach plate.

Drive

Bug note: The tubes that go around the threaded rods are not shown in the diagram.

- Attach the coupler on the motor to the drive shaft with the 1/2" x 4"bolt.

- Fit the motor and coupler to the main rotor shaft, P21. Pass the 12" long, 1" threaded rods through p24 then through the tubes (not shown), through p23 and thread them through the nuts welded to the far side of p4.

- Attach the 4 further nuts to clamp the motor to the tubes, and the tubes against p23, in a sandwich.

- Tighten the screws in the collars of the bearings to the shaft.

Quality control checklist

- Ensure the system rotates freely 360 degrees. If the coupler, motor and shaft are not on the same axis, it may lock up.

- Check that when torque is applied to the motor, in either direction, there is no excessive twisting.

Teeth

Procedure

- Take p18

- Lay p19 flat

- Weld p18 with 1" overlap onto center of 19

- Weld p20 to make about 3/4" of 19 exposed at the cutting edge

- Repeat for the total 12 teeth

- Weld 4 teeth at the proper spacing (6" on center and 3" on center from the edge) to part 15 (tooth bar bolt bar), with 4 inches overlap between 18 and 15, protruding from the side of the plate that is farthest from the holes. Make sure the tooth bar bolt bar is oriented correctly relative to where the teeth are placed. The teeth go on the side farthest from the bolt holes.

- Repeat for the 2 other p15 shaped parts

- Grind teeth at 45 degree angle with tooth bar weldment in a vice

- Water harden or air harden the teeth by heating to red hot with acetylene torch and then dunking in water

Quality control Checklist

- Make sure that 18 and 19 overlap by 1"

- Make sure that 18 and 19 are centered with respect to one another

- Make sure that at least 1/2" on the cutting edge is exposed after grinding

- Make sure that 15 is oriented with the side closest to the holes on the far side from the teeth

- Make sure that the angle between 15 and 18 is 90 degrees

Quick Attach Finger

- Tack 2x P34 ends onto the outside of P1, using p10 as a guide.

- Tack p10 in place

- finish the welds along all seams on the inside and outside for these parts.

- Move the quick attach plate into position on the finger.

- Bolt p13, the side tabs, in place on the Quick Attach unit.

- tack the P13 parts to P1.

- Unbolt and remove the QA plate.

- finish welding p13 to p1

Lid, stage 1

- Tack P25 at a 90 degree angle along the length of the bottom of the lid.

- Tack 2x P26 Lid Struts onto the ends of the Lid at a 90 degree angle. Ensure a 1/4" space at the top for 2x P29 to fit later (after the hinge and hydraulics are added)

- Place the lid into the seal, so that it rests with equal clearance on the left and right side (should be 1/4" each side), and equal on the top and bottom. The perimeter of the lid should be congruent with the perimeter of the lid seal ledges/lips.

- Tack 2x P31 hinge pieces in position. Note that p31 is not right up against p33. There is a washer in between them.

- Also ensure the outside faces of the hinges are flush with lid struts P26 on the ends.

- Check for fit by passing the hinge rod through the holes in the pieces.

- Finish the welds.

Hinge

Passing the rod back into the hinge, ensure the following list of parts are threaded onto the rod in order-

- P33

- a washer

- P31

- P11

- a washer

- Cylinder base

- a washer

- P11

- P31

- a washer

- P33

This is a temporary arrangement to get the hinge in place and centred. Later we will remove the cylinder, washers, and P11 parts.

- Measure to centre the 2x P11 and 2x P31-shaped parts in the middle (there are 4 total) along the QA Lip. the 2x P31 centre hinge pieces should be aligned with the 2x P31 outer hinge pieces along the QA Lip P10 with the 4.625" between them, and 31.1875" between the p31 inner and outer pieces, face to face. The p11 parts are just being used as temporary spacers of suitable thickness with a convenient sized hole here.

- Tack (dont finish weld yet) the outer seams only of the P31 piece onto the QA lip.

- Carefully take out the shaft and remove the cylinder, P11 supports, and the 2 on the Cylinder. Place the shaft back in with the other parts listed above still loose as they were before.

- Get someone to hold the cylinder base so the the very bottom edges of the P11 supports are aligned with the bottom edges of the center P31 hinges and clamp them together with G-clamps. Leave enough clearance with the clamp to later weld on the seams. You might want to use the bolt intended for the rear cylinder pivot to attach the p11 parts to the cylinder temporarily.

- Using a set square to ensure P11 and P31 are perpendicular to P10, Tack all seams between P11, P10, and the p31 parts.

- Finish the welding the seams on these parts and remove the clamps.

Left Lid Hydraulic Attachment to Hinge

- Lightly clamp P33 onto P31 maintaining the 90 degree angle in the joint as in the diagram. Since there is a washer in between on the shaft, 2 clamps may be required to keep everything flat.

- Take one of the middle p33 and clamp to the middle p26 shaped piece. Place p26 against the lid, align things, and weld in place.

- Ensuring the Hydraulic cylinder is about 1/4" back from full extension (to ensure the lid can fully close, but we don't want it to continue to extend much after full closure), bolt 2x P14 cylinder struts on to the cylinder, along with the spacers and washers. There are washers on both sides of P14 Parts (4 washers, 2 spacers total). dev: what spacers? They are not mentioned anywhere else at all, not in the design, bom, anywhere. You can use washer here maybe, but the spacing won't be perfect. This is not a good way to get the p14 pieces to have the right spacing unless we have passably accurately cut spacers. On one side a nut can be used, but on the other, there are no threads there.

- Rotate the cylinder about the base etc to get the first P14 strut in position. it should be flat against the inside of P33. tack in place, ensure it is perpendicular to the lid with a set square and finish welding the seams.

- Repeat this process with the right side

- Weld the 2x P27 Gussets in place against P14 and the P2 Lid.

Top Lid Struts

- The 2x P29 pieces can now be tacked and welded onto the lid between the P26 Lid struts and P33 Hinges.

Shaft

- Take out the shaft enough to give some clearance on the left end (End nearest to motor). Weld one of the end washers on, staying clear of the second washer.

- Put the shaft back and measure and mark a distance on the other side of the shaft to put a cotter pin through.

- Carefully take out the shaft all the way and drill the hole for the cotter pin.

- Fit the shaft back with all washers and lid in places.

Fit digging teeth

Hydraulics

?

Attach lifetrac

Digging teeth

open the lid after testing hydraulics, place a support underneath the lid for safety, and lift the bucket off the ground using the Lifetrac arms.

Fit the 3x p15 plates with digging teeth and 1" bolts.

Fabricate, in order:

Note: There is a lot of steel in this thing, and some of the parts are quite heavy. Where suitable, be generous with your tack welding accordingly, to ensure adequate

strength. 1. The tine modules, which together with the rotor shaft and coupler, forms the rotor module Soil_Mixer_-_Rotor_Module_-_Build_Instructions

+ I recommend making a singe tine module first, to see the process working, before cutting and welding in batches. This ensures that all equipment is working etc.

- cut the 3" pipe sections with a cold cut saw

- Cut the tines from the 1/4x2" stock, 4" each, using the ironworker. 72 of them.

-lay the tines out on the ground with the corners touching, and tack weld them together.

-put the 3" pipe section in a vice and place the tines in position around it, then tack them together.

-cut the hole in the side of the pipe for the bolt to pass through with an oxy acetylene torch.

- tack weld the nut on.

- Complete all welds while the tine module is in the vice.

- Remember there are 2 different tine module varieties, 9 of each type, the only difference being the radial position of the nut and associated hole in the side of the

pipe is different by 45 degrees. This ensures that only half of the tines hit the surface of the soil at any given time.

2. Then the rotor shaft Soil_Mixer_-_Rotor_Module_-_Build_Instructions - Cut the rod to length. - using an angle grinder, grind 1/4 inches down one side of the shaft. For the bolt ends to lock against. - drill the hole along the diameter at the end of the shaft for the 1/2" coupler bolt/shear pin. You may be able to get away with putting the 6 spline coupler on the

end of the shaft and using the existing holes in it as a guide for a mag drill to drill the hole. Start the drill hole perpendicular to the flat ground side of the

shaft. - the key for the shaft-coupler connection is not yet addressed in this draft of the instructions.

3. The lid, with integral hinges.

4. The tooth bar -Cut the rebar and stock to size. -tack weld the 5. The bucket, which includes the means to connect it to the tractor arm and hinges for the lid.

-Tack weld the side triangular pieces to the bottom. -add the back after -add the back finger and the small triangular cross bracing piece. -add the side tabs - add the two side hinge pieces - using the hinge rod if you prefer to aid alignment, add the 2 center hinge pieces. - add the piston support pieces.

The other parts are off the shelf, including the motor coupler, motor, and hydraulic piston used to lift and close the lid.

This document needs to be expanded into more detail, and will be later, as it must before the fabrication actually starts.Assemble, at this point the welding is all

done:

1. The bucket and rotor module:

a) Insert the rotor shaft through one bearing, might as well be on the side which does not have the motor mount. Remember to orient the shaft so that the hole for the

coupler is on the right side.

b) Get those tine modules onto the rotor shaft. Don't tighten the bolts yet.

c) Fully insert the shaft through the bearing on the other side. Tighten the bolts on the bearings to attach the inner collar of the bearing to the shaft.

d) Attach the motor coupler

e) Attach the motor. Ensure the hydraulic couplers are pointing towards the tractor.

f) Tighten all bolts to final tightness, including all bolts on the tine modules

2. Attach the tooth bar.

3. Attach the lid.

4. Attach the hydraulic piston.

Ensure all bolts are tight, everything moves as hoped, and you are ready to attach it to the tractor.