Pattern Language

Introduction

Technology may be broken down into a collection of fundamental building blocks or modules that make up technological devices. When one understands how technological things work, it turns out that there is a rather small set of underlying building blocks that much of technology has in common. Modules or building blocks of technology may be identified. These building blocks are like words that make up sentences. If we can understand the words, or building blocks, then we can master the language, or technosphere.

The key benefit of a pattern language is the transparency that it sheds on a subject. This is the aim of exposing the underlying components of all technologies - so that people can understand the technology around them. Only when non-specialists begin to understand technology will humanity be able to master its technological base. When this happens, humans cease being slaves to poor technology choice.

To understand the pattern language of technology, we began breaking down technological devices into their components. Here we discuss one possible breakdown.

We chose a small set of technologies for building the infrastructure of Global Villages of tomorrow. These technologies are those discussed on the main page.

All of these technologies have a smaller set of underlying building blocks that they are made of. This set of building blocks may be broken down to only 18 items:

These items are somewhat self-explanatory. Please view our past work for further explanation of this open source technology pattern language. The present work develops this theory further.

Open Source Technology Pattern Language

The technological components of interest in the Global Village Construction Set constitute basic building blocks of economies. More complex products and devices may be represented by a collection of icons. We remind the reader that the proposed set is not complete, but sufficient- applicable in a broad range of applications. Other technologies may and should be used where appropriate.

It should be underscored that any community interested in its own self-determination should: (1), have production capacity of the essential components as part of its own infrastructure, or, (2), should have external relations established for providing these technologies without incurring geopolitical compromises. We are talking of basic needs here– and the basics must be provided internally to secure stable society by design.

Note that not all of the Global Village Construction Set technologies of interest are represented in the picture above. This is because some of these are represented by combinations of the above icons. The last 5 icons in picture represent the major parts of a flexible fabrication facility.

The difference between the past work and the picture lies in a few updates that arise from experience gathered since the former report was published. There are 4 main differences.

The first difference is that the new set eliminates the former pulley and the power transmission icons, as well as the electric wheel motor and electric motor (see last link) and replaces them with the wheel motor shown in the picture above.

Wheel Motors

Wheel motors are high power, low speed electric motors that may be coupled directly to wheels, or other rotors, for powering vehicles or other electromechanical devices without the need of power transmission. They have no internal power transmission, either – as they are inherently suited to many direct-drive applications by design. The subtlety here is the proposition - known well in progressive vehicle design (such as Hypercars ) – that the availability of such wheel motors produces a great simplification in vehicle design. Pulleys, gears, and other power transmission devices – including drive shafts, differentials, clutches, and transmissions – not to mention grease and oil pans - are eliminated for gross simplification in the overall complexity of cars and other electromechanical devices. Moreover, the former electric wheel motor - which was a standard, high speed motor that included gearing in the icon set from 2006 – is eliminated for the same reason, ie, that power transmission has been designed out of the technology set.

The key to this elimination is that advanced electric motor controllers, combined with the new wheel motors (high power, low speed) are able in themselves to produce the necessary dynamic range of speed and power that was formerly achievable only with various forms of mechanical transmission – typically gears and pulleys. Advances in electronics have made the former option obsolete – though the new choice is presently rarely used, due to industry inertia.

The second difference is the elimination of the electrical generator icon, because electrical generators are contained in wheel motors. Wheel motors are electrical motors, and electrical motors operated in reverse (ie., spun externally instead of spun by electricity) function as electrical generators. To eliminate this redundancy, we are eliminating the separate electrical generator icon and replacing it with the wheel motor. This simplifies the set of OS technology icons.

Boundary Layer Turbine

The third difference is the elimination of the 6 hp stationary diesel engine, the 23 hp mobile diesel engines, as well as the steam engine, and replacing them with the boundary layer turbine. Our present research indicates that the boundary layer turbine is a robust, lightweight, efficient, stationary or mobile engine that has the fuel flexibility and application flexibility that makes the former options obsolete. Diesel engines and steam engines are much more complicated to build than the boundary layer turbine, which consists mainly of a shaft with a dozen or so closely-spaced, flat disks acting as propellers for transforming the energy of a working fluid into rotary motion. Since we have verified performance data in the literature (Rice, Warren, "An Analytical and Experimental Investigation of Multiple-Disk Turbines", Transactions of the ASME, Journal of Engineering for Power, Jan. 1963, pp.29- 36.), and identified a prototyping firm capable of delivering a working turbine, we decided to pursue it as a short-term feasible item. Steam engines still appear attractive, and are simpler to fabricate than diesel engines, but their low efficiency (approximately 1-8% overall efficiency for a basic system ) makes them appear to be an inferior option. Modern gas or diesel engines and standard bladed turbines are avoided due to high complexity.

The fourth difference is the addition of the following icons, which are also components from the 16-technology set: boundary layer turbine, solar concentrators, flash steam generator, plus the tools used in flexible fabrication: CNC Multimachine, XYZ table, metal casting, plastic extrusion, and electronics fabrication.

There are a few minor changes as well. The heat generator now will be made explicit as the Babington burner or other type of fluid fuel burner, and is distinct from the solar concentrators due to the different nature of these two heat sources. One is solar thermonuclear energy, and the other is chemical combustion energy. The heat generator may in principle also be an electric heating element, but it should not include man-made thermonuclear power, for ecological reasons.

Also, the former motor controller icon was renamed as power electronics, which includes the motor controller, and more specifically: battery chargers, DC-AC inverters, DC-DC converters, AC-AC transformers, solar charge controllers, PWM DC motor controllers, and multipole motor controllers. This set of power electronics covers off-grid energy and vehicle propulsion infrastructures.

Last, he fuel icon shall include both fuel alcohol and compressed gas.

Product Ecology: Symbolic Representation of 16 Global Village Construction Set Technologies

To simplify the discussion, it is first instructive to represent the 16 technologies with icons. We have already shown the icons for the boundary layer turbine, solar concentrators, Babington burner (This is a type of heat generator, and is used for efficient burning of various waste oils, from crankcase, vegetable, to hydraulic oils. This type of burner was chosen specifically because it can burn widely available and typically free (in the USA) waste oils. Note that oil fuel is merely transitional, and will be replaced with other alternatives.), flash steam generator, wheel motor, generator (same as wheel motor), plastic extruder, CNC Multimachine, XYZ table, metal casting, and electronics fabrication. Fuel alcohol and compressed wood gas may be shown by the fuel icon. Only the CEB and Sawmill haven’t been shown. The simplified CEB icon set, when the machine is powered by an external power source such as hydraulic takeoff from an agricultural tractor – is:

Compare this to the CEB icon for a machine with a built-in power source, shown in the past work . This is one of the many simplifications and refinements to the technology base that we have produced since two years ago. We basically have a structure, with two linear motors (hydraulic cylinders), which move the compression cylinder and hopper, respectively. Compare this to the actual picture of the machine:

The sawmill is:

The sawmill consists of a wheel motor connected to the cutting blade on a rotor. There is also a structural frame, to support the blade, and to hold the log that is being cut. An electric motor controller controls the cutting speed. The propulsion system (engine) of the sawmill has not been shown for clarity. Our present implementation of a sawmill is:

This leaves aluminum extraction from clay. This is too difficult to break down to an icon, as it is a multi-step process.

Product Ecology: Interaction of the 16 Technologies with a Land-Based Global Village and with the Global Economy

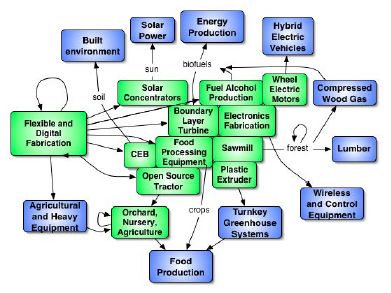

The 16 technologies are building blocks for an integrated infrastructure and productive capacity, as implied by:

In this process, local resources are used whenever possible. The 5 last technologies – the Fab Lab for the means of fabrication – may be used to fabricate all the other technologies from scratch – including the means of fabrication themselves. This is what is meant by the closed arrow loop in the above figure for Flexible and Digital Fabrication. The Fab Lab is responsible for technological self-replication. The nursery is responsible for plant self-replication – namely fruit trees. Animals are also self-replicating in a land-based facility, and they are a contribution to an integrated ecology. In this sense, the whole package is self-replicating. Combined with the low cost of the various components, and the documentation and training that Factor E Farm aims to generate, the whole package is meant to constitute a highly-replicable instance of a Global Village.

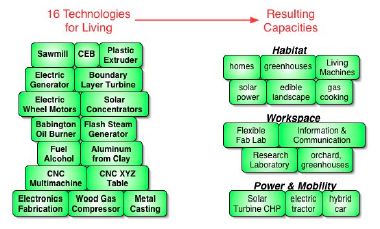

Food and habitat, a working environment, mobility, and energy are all based on the 16 technological building blocks. This is shown here:

Moreover, these building blocks are the foundation for a wide range of possible enterprises:

- Solar turbine CHP systems

- Turnkey greenhouse systems: This includes glazing extrusion and fabrication of modular greenhouse panels using dimensional lumber and extruded glazing. SolaRoof insulated greenhouse panels are of particular interest.

- Hybrid car fabrication – turnkey product, kits, and weekend workshops- come and build for yourself in an extended weekend workshop

- Hybrid electric tractors – turnkey products, kits and weekend workshops

- Skid loaders

- Green building design-build operations - including Living Machines and attached greenspaces. Focus is on shell houses, adaptable living space, and potentially non-greenhouse dynamic liquid insulation.

- Global Village development companies

- General custom fabrication and prototyping

- Flexible and digital fabrication facility construction

- CEB machine production, brick sales

- Sawmill production, custom sawmilling

- Fuel gas and fuel alcohol facility development; mobile rental units

- Rotor fabrication - pumps, vacuum pumps, compressors, boundary layer turbines, wheel motors, generators, others

- Remote electric power systems

- Biodiesel production equipment rental

- Flooded lead acid battery building

Secondary enterprises requiring know-how more than hardware:

- Orchard, nursery, greenhouse, dried fruit, plant products, freeze-dried fruit powders, and edible landscaping operations

- Computing – computer building, software installation, networking, data acquisition, machine control

It should be pointed out that a particularly exciting enterprise opportunity arises from automation of fabrication, such as arises from computer numerical control. For example, the sawmill and CEB discussed above are made largely of DfD, bolt-together steel. This lends itself to a fabrication procedure where a CNC XYZ table could cut out all the metal, including bolt holes, for the entire device, in a fraction of the time that it would take by hand. As such, complete sawmill or CEB kits may be fabricated and collected, ready for assembly, on the turn-around time scale of days. If one were to sell such kits, that leaves room for large profit margins while selling the machines at a competitive price. This is indeed a fundraising model that we’re considering for funding further open source development.

The digital fabrication production model may be equivalent in production rates to that of any large-scale, high-tech firms. Moreover, by keeping overhead down via open source design, production can occur essentially at the cost of materials. Digital fabrication product may be able to compete with globalization in terms of price itself, for many technological items. Consider mass production slave goods from China. It is foreseeable that digital fabrication has great potential in transcending the negative effects of globalization – such as returning manufacturing jobs from China to the united States. This type of localization program merits serious consideration.

We do not foresee competition from large firms on goods like sawmills or CEBs, simply because we can compete in price. Digital fabrication may prove so effective that we can be cost-competitive even in the face of slave labor, as practiced commonly in global supply chains. Not only can the price be competitive, but the local service, lifetime design, easy maintenance, and open source documentation simply cannot be matched. Localization has the potential to beat globalization in many areas, but it must be said that brave pioneers are required to lead this movement. It is required that the open source flexible and digital fabrication technology is open-sourced and optimized, and breakthrough economic patterns will emerge. Indeed, reduction of slave labor may occur, as such practice may prove uneconomical in the face of localization.

Sample Product Ecology 1: Energy – Solar Turbine Combined Heat and Power (CHP) System

We now turn to particular examples of product systems that arise as a combination of the 16 technologies of interest. One product is a solar turbine CHP system for our facility:

The heart of this system is a boundary layer turbine electrical generator (blue part in picture). This is the heat engine that converts a source of heat into electricity. Heat is used to generate steam in a heat exchanger. This steam spins the turbine. The turbine is connected to an electrical generator, and power electronics deliver the electricity for storage in batteries or utilization in a grid. Three sources of heat that we are considering are solar energy (solar concentrator icon), the Babington burner (green part in picture ), or heat storage (heat generator icon).