Open Source Car

The OS Car will be a lightweight and aerodynamic two passenger long range car that will be fueled with ethanol biodiesel. The current plan is for the car to have a reverse trike configuration: two front wheels and one rear wheel which is the only driven wheel. The two main benefits of the reverse trike design are lower cost and weight due to one less wheel, and lower wind drag due to the rain drop shape of the body. The construction of the car will be a steel space frame covered with non-structural polymer or composite panels. The proposed powertrain is a hybrid hydraulic system which includes a single cylinder engine that runs a hydraulic pump which directly powers a hydraulic wheel motor used to drive the car and which compresses a gas in an accumulator to store energy. Gas in the accumulator will also be compressed via regenerative braking when the hydraulic motor is run in reverse to slow the car down. Cost control and quick development will be maintained by using donor vehicle parts and off-the-shelf parts. Components that cannot be easily manufactured such as brake calipers, steering knuckles, and rims will be sourced from a donor vehicle and components such as instruments, wiring, and hydraulic components will be off-the-shelf components.

As the car design matures, some components from donor vehicles and off-the-shelf components can be replaced by scratch-built open source components. Also, forks can be made from the original car design for variants such a four or five passenger car, or perhaps a car with a hybrid electric powertrain.

Development Page

These are the GVCS development steps that take place for Distributive Economics development of the GVCS tools. These 32 steps apply to each prototype of the GVCS machines, and each machine iterates through 3 prototypes prior to Full Product Release.

Instructional Page

Design Rationale, Conceptual Diagram, Bill of Materials (with weblinks to sources), Demo Video, Demo Photos, Instructional Video (A to Z on the fabrication), 3d CAD file (metal fabrication), 2d fabrication drawings (metal), 2d electronics design file to build circuit boards, wiring diagram, Machine-readable CAM files, 2d Exploded Part Diagram, Computer Software Control Code for Automated Devices, Hydraulic Circuit Diagram, Calculations (for scaling purposes)

User Manual Page

Information on how to operate and maintain the OS Car Specifications on the OS Car

Other Opens Source Car Projects

Other projects which may be interested in collaborating:

- http://www.theoscarproject.org/ - German project

- http://www.authenticbusiness.co.uk/archive/oscarproject/ - UK project

- http://news.windingroad.com/concept-cars/meet-cmmn-the-worlds-first-open-source-car/ - Netherlands project

- The Rally Fighter - a completed open-source car

- HyrBan, an open-source, hydrogen-powered car. In prototype phase.

Help Wanted

We are currently looking for people to take on the following roles in the OS Car project:

- CAD designer

- Suspension subject matter expert (SME). The currently plan is to use an unequal length double A-arm suspension (http://en.wikipedia.org/wiki/Double_wishbone_suspension) for the front wheels and a motorcycle rear suspension for the rear wheel.

- Vehicle aerodynamics SME. We need this SME to give some input for basic dimensions of the car early in the design stage and to later run CFD simulations and design the shell body for the car. --Crank 12:00, 14 May 2011 (PDT)

Modularity

One basic objective of the OS Car project is to exploit modularity in the powertrain design. That is, as many components as possible in the OS Car powertrain will be shared with power delivery systems on other GVCS machines. This is being attempted by designing the powertrain as a hybrid hydraulic system which will utilize the following modular components:

- primary power source output, currently chosen to be a single cylinder internal combustion engine running on alcohol. This engine will have an output from 10-20 HP and can be potentially be used in multiples in machines that require more power.

- hydraulic motor used to drive the rear wheel

- tubes and hoses for routing hydraulic fluid

- an accumulator for storing power

--Crank 21:23, 14 May 2011 (PDT)

Hydraulic Hybrid Powertrain

The OS Car powertrain will be a Hybrid Hydraulic System, making it a hybrid hydraulic vehicle (HHV). A hybrid hydraulic system was chosen over a hybrid electric system to avoid the weight of numerous lead-acid batteries or the cost of lithium-containing batteries. Since one of the objectives of the OS Car will be a long range, i.e, the capability to travel perhaps over a thousand miles without stopping to refuel or otherwise obtain more stored energy, the potential plug-in capability of a hybrid electric powertrain is not heavily valued.

- Check out Hybrid Hydraulic Drive Thesis

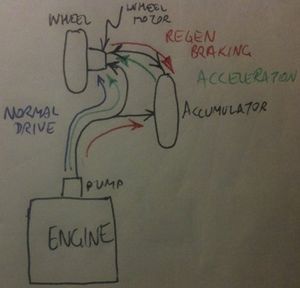

OSE Proposition: Motor powers hydraulic pump. Hydraulic motor is direct-coupled to wheel or coupled to the wheel via a driveshaft or belt. H-bridge hydraulic drive (see Thesis above) circuit either freewheels, regenerates power (braking, red line), accelerates (green line), or does normal driving (blue line).

Chassis

The current plan is for the car to be a reverse trike with two wheels up front and one wheel in back. The benefits to a reverse trike are: less weight due to one less wheel, less variable cost due to one less wheel, and better aerodynamics due to the tapered rear end that can be achieved. Federal regulation requirements are much less onerous for a three-wheeled car than a conventional car which allows for a much lower cost to develop the vehicle. Many state regulations might also be avoided since many/most states treat a three-wheeled vehicle as a motorcycle (Need to research this.) Using a three-wheel design would allow for the back wheel to be directly driven which would obviate a differential, shafts, etc. See the Aptera for an example of a car with a shape that fully exploits the reverse trike configuration: www.aptera.com. --Crank 20:36, 11 May 2011 (PDT)

- Frame

The frame should be a space frame, probably composed mostly of 4130 or cheaper steel tubes. Square or rectangular section tubing is probably better than round tubing for most of the vehicle since it is stiffer in bending for a given amount of weight. Currently I'm working a chassis design based on a Locost frame model from www.sevenesque.com/3d-models. Here's a picture of what I have so far (the Locost frame with some NB Miata parts):  --Crank 20:26, 11 May 2011 (PDT)

--Crank 20:26, 11 May 2011 (PDT)

- Running Gear

The current plan is to use most of the running gear: tires, wheels, brake rotors, brake calipers, steering knuckles, steering rack from an NB Mazda Miata donor car on the OS Car.

- Steering

We need to decide whether the car has front or rear wheel steering. I favor front wheel steering because it will make design of the car easier and probably cheaper because it will allow for more off-the-shelf parts to be used. I also think that front wheel steering will allow for better collision avoidance since, unlike rear wheel steering, it would not cause the rear of the car to initially move toward an object which a driver is trying to avoid. Handling at high speeds and extreme manoeuvres is probably also worse with front steering if the the info here en.wikipedia.org/wiki/Steering#Rear_wheel_steering applies to reverse trike vehicles. --Crank 20:26, 11 May 2011 (PDT)

Marcin and I decided to use front wheel steering rather than rear wheel steering to avoid possible controls issues with rear wheel steering and to avoid the task of designing a novel steering mechanism for the rear wheel. The current plan is to use the steering rack from the same Miata donor car that provides the wheels, brake rotors, brake calipers, steering knuckles, and other parts. --Crank 22:03, 14 May 2011 (PDT)

- Suspension

Front: An unequal length double A-arm suspension will be used to achieve optimal control. --Crank 11:47, 14 May 2011 (PDT) The current plan is to use rotors, wheel hubs, and steering knuckles from a NB Mazda Miata for the front wheels. The Miata is a the best donor vehicle candidate that I found for front suspension parts because it's a rear wheel drive vehicle like the OS Car will be, the suspension has an unequal length double A-arm design which is optimal for performance, and because the hubs have a 4 x 100 mm stud spacing which allows for a wide array of choices for rims and tires. --Crank 20:26, 11 May 2011 (PDT)

Rear: The current plan is to use the rear fork, springs, shocks, and wheel from a motorcycle. I'm currently leaning toward a Goldwing as a donor because an older donor can be found for a good price and because they have shaft drives which are quieter and require less maintenance than belt or chain drives. --Crank 18:39, 13 May 2011 (PDT)

- Wheels

The wheels will have a 15 inch radius and will be obtained from the donor car.

- Tires

The tires will be obtained from the donor car or low rolling resistance tires will be purchased if funding exists.

Body

The body will be composed mostly of of non-structural panels that will bolt to the frame via soft mounts. --Crank 12:00, 14 May 2011 (PDT) The body will have a the desired low wind drag teardrop shape which is only possible with the reverse trike layout and exploited on several other ultra fuel-efficient vehicles such as the Aptera, Urbee, and the NmG. --Crank 21:06, 14 May 2011 (PDT)

Fuel Efficiency Calculations

Some general unorganized thoughts from Mark Rudnicki on the Open Source Car:

- Basing the OSCar on the Urbee would allow for radically faster development than starting from scratch. I suggest that Marcin contact Jim Kor and make a pitch for him to open source the Urbee.

We contacted Jim Kor, and so far, he has decided not to open source the Urbee. --Crank 21:29, 14 May 2011 (PDT)

- RepRap machines or modified larger versions could be used to produce the body panels for the OSCar, but it's unknown how resilient these panels would be to things like bumping and extreme heat and cold. If we find that RepRapped panels are not durable enough, then perhaps RepRap machines could be used to produce forms from which fiberglass or carbon fiber composite body panels would be produced.

- Using a hybrid hydraulic system would allow us to exploit Power Cube technology. The drive wheel would be coupled directly to a compact hydraulic motor. Regeneration from braking could also be conveniently exploited.

- Using a fairly large accumulator would allow for good city fuel efficiency and good acceleration (highway safety).

- The coefficient of drag of the Urbee is quite good: 0.146 according to http://en.wikipedia.org/wiki/Automobile_drag_coefficient.

- Plastic windows are preferred due to their lower weight over glass windows, but the windshield may have to be glass due to scratching problems with plastic.

- As many off-the-shelf parts as possible should be used to allow for quick development. Such parts could later be replaced by similar open source parts.

- A rough calculation for fuel efficiency for a maximum cruise speed of 60 MPH is about 130 MPG. An engine designed to run at peak efficiency at 6 HP would be required for this max cruise speed.

- A rough calculation for fuel efficiency for a maximum cruise speed of 70 MPH is about 100 MPG. An engine designed to run at peak efficiency at 10 HP would be required for this max cruise speed.

- The engine must have a electric starter and electronic fuel injection (EFI) (http://en.wikipedia.org/wiki/Fuel_injection#Electronic) in order for it to start quickly and reliably in all weather conditions. Engines with EFI are also more fuel efficient (perhaps 25% more) and less polluting than those with carburetors. A hybrid hydraulic version of the OSCar will by design have an engine that regularly starts and stops during city driving.

- The smallest production gasoline engine with EFI that I've been able to find so far is the Subaru Robin "EX21 Fuel Injection" (http://robinamerica.com/pfeatures.aspx?pid=226) which has a maximum output of 7 HP. Peak fuel efficiency is assumed to occur at peak torque, which, according to this plot: http://robinamerica.com/media/images/diagrams/226/0_l.png, occurs at 2400 RPM where output power is only 4.8 HP. At an output power of 6 HP, engine speed is about 3100 RPM, where torque is only about 5% lower than peak torque, where efficiency is still probably pretty good at this speed, making the EX21 a good candidate for an OSCar with at cruise speed of 60 MPH. At max engine output at 4000 RPM, where fuel efficiency is lowest, a top speed of about 63 MPH is predicted.

- This engine comes with a pull start, so an electric start from a similar Subaru Robin model would have to be fitted to it.

- We'd also need to figure out how to connect an alternator to this engine.

- I couldn't find a price on an EX21 with EFI online, but found an EX21 without fuel injection new for $381. I conservatively estimate the price of the EX21 with EFI to be $600.

- The next smallest gasoline production engine with EFI that I've been able to find so far is the Kohler ECH630 (http://www.kohlerengines.com/onlinecatalog/productDetail.htm?productNumber=Command%20PRO%20EFI%20ECH630) which has a maximum output of 19 HP. Peak fuel efficiency is assumed to occur at peak torque, which, according to this plot: http://www.kohlerengines.com/onlinecatalog/jpg195x290/ech630_max_torque.jpg occurs at 2800 RPM where output power (http://www.kohlerengines.com/onlinecatalog/jpg195x290/ech630_max_power.jpg) is 16 HP, which is well over the 10 HP required for a 70 MPH cruise speed. At an output power of 10 HP, engine speed is a bit over 1800 RPM where torque is about 7% lower than peak torque, where efficiency is also still probably pretty good, making the ECH360 a good, but oversized candidate for an OSCar with a cruise speed of 70 MPH. At max engine output at 3600, where fuel efficiency is lowest, a top speed of about 88 MPH is predicted.

- I received a price quote of $1607.46 plus $70 for freight for an ECH630 from a Kohler dealer on April 25, 2010.

- Although, the EX21 and ECH360 are designed to run on gasoline, it's assumed that the primary fuel for the OSCar will be ethanol.

- Technical requirements for adapting these engines to run on pure ethanol or at least E85 are unknown. At the very least calibration of the ignition and fuel injection systems would have to change.

- One hope is that a variant of the ECH630 that's compatible with E85 (http://en.wikipedia.org/wiki/E85) fuel will eventually be available (http://www.kohlerengines.com/common/pdf/EIA_WinterMarch09.pdf). An inquiry to a Kohler engine dealer on April 25, 2010 regarding use of E85 in Kohler engines netted no information.

--Crank 09:57, 25 April 2011 (PDT)