Motor selection

The selection of motor includes the following steps (which are described in further detail on this page):

Step 1) Note the load characteristic.

Step 2) Consider the needed power (torque and speed.)

Step 3) Select motor type.

Step 4)

Step 1) Note the load characteristic

There are three different load characteristics:

- Torque that is constant

- Torque that changes abruptly

- Torque that change gradually over time

Note which of these three correspond to your application.

Step 2) Calculate the needed power

To know the needed power, you must first know

- the torque

- the speed

Therefore, this step is broken down into three sub-steps: 2.1) Calculate the needed torque. 2.2) Note the needed speed. 2.3) Calculate the needed power.

2.1) Note the needed torque

T = F * r

where

T: Torque

F: Force

r: Radius

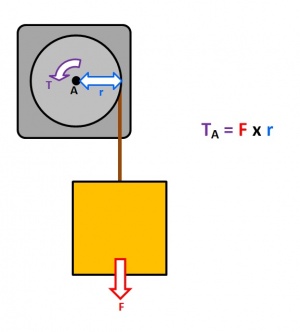

Consider the image to the right as an example for understanding Torque. It shows a pulley connected to a motor lifting a box via a rope. The torque will act on the point A.

The box will pull down with a force:

F = m * g

where

F: Force

m: Mass

g: Gravity of Earth

The gravity of Earth is 9.81 m/s2. Let's assume the mass M of the box is equal to 10 kilos. The force F is then calculated like this: F = m * g = 10 * 9.81 = 90.81 kg * m/s2 = 90.81 N.

The next step is to multiply the force F by the radius r (the distance from point A to the edge of the pulley.)

Let's assume the radius r is equal to 0.1 m. The Torque will then be calculated like this: T = F * r = 90.81 x 0.1 = 9.81 Nm.

2.2) Note the needed speed.

Speed N is measured in RPM (revolutions per minute). Note the needed speed for your application.

2.3 Calculate the needed power

P = T * ((2 * pi * N) / 60)

where

P: Power

T: Torque

N: Speed

If the Torque was calculated to 9.81 as in the example above and the speed was assumed to be 10 RPM, the power is calculated like this: P = T * ((2 * pi * N) / 60) = 9.81 * ((2 * pi * 10) / 60) = 1.047 Watt

Step 3) Select the motor type

Here we select one of three motor types.

Servo motors are suitable for high speed and high acceleration requirements. The trade-off is a higher cost and complexity.

Stepper motors are suitable for low speed and low acceleration requirements.

DC motors are suitable for continuous rotation at high RPMs and constant torque across the motor’s speed range.

| Attribute | Stepper motors | Servo motors | Brushed DC motors | Brushless DC motors |

|---|---|---|---|---|

| Accuracy | High | High (achieved by adding encoder to the system. | None | Varies |

| Torque at low speeds | High | High | - | - |

| Torque at high speeds | Low (can lose up to 80% torque at high speeds) | High | - | - |

| Cost efficiency | High | Lower (uses rare-earth magnets, may need encoder or gearbox.) | High | Lower |

| Lifespan | Long life | Shorter | Shorter | - |

| Size | Compact | High output power relative to size and weight. | Compact | - |

| Load capacity | Low (might skip steps at high loads.) | High | - | - |

| Efficiency | Low (constantly draw maximum current independent of load.) | High (80–90% efficiency.) | High | - |

| Ease of use | • Easily controlled (can be controlled with micro controllers such as the ATmega chips that are readily available on Arduino development boards.) Can stall or lose position without a control loop. | • Higher maintenance if gearbox and encoder is included.

• Limited range of motion; positional rotation servos are limited to 180 degrees of motion. • Works in AC or DC drive. |

• Torque to Speed Ratio can be altered (exclusive to brushed motors.)

• High maintenance requirements due to easily worn out as a result of continuous moving contact. |

• Some brushless motors are difficult to control and require a specialized regulator.

• Low maintenance. |

| Applications |

• floppy disk drives • flatbed scanners • computer printers • plotters • slot machines • image scanners • compact disc drives • intelligent lighting • camera lenses • CNC machines and 3D printers • Textile machines • Printing presses • Medical imaging machinery • Small robotics • Welding equipment |

• Automated manufacturing • Robotics • CNC machinery • Telescopes • Elevators • Conveyor Belts • Camera Auto Focus • Solar Tracking System • Metal Cutting & Metal Forming Machines • Antenna Positioning • Printing Presses/Printers • Automatic Door Openers |

• Home appliances • toys • electrical propulsion • cranes • paper machines • steel rolling mills |

• Drones • Electric cars • Washing machines • Air Conditioners • Cordless tools • Computer • Fans • Disk drives |