UELVE MBC/v0.1

Basics

- A lightweight (200 kg) 3 occupant vehicle design that can be mostly DIY constructed.

- Although intended as an EU Category L7e "Heavy Quadricycle" it can also be the basis for a USA "NEV" or a pedal-car, or E-bike "pedal assist" motors installed.

- Dimensions 1.5 x 3.1 x 1.1 metres for a front surface area of approx 1.5 sq. metres

- Geodesic Frame skeleton is bamboo and PVC pipes connected together with 3D-printed software-generated "Nodes", which are then entirely encased in Expoxy Resin and Fibreglass, Kevlar, Hemp, Flax or other high-strength cloth layers.

- Double wishbone suspension is expected to be fitted at the front, whilst the rear may be swing-arm, Double-wishbone or Macpherson. This revision uses swing-arms at the rear.

- Body panels are twin layers of Fire-resistant Non-woven Polyester with a hot-glued 4 layer latticework "Hobbycraft" 9x1mm bamboo frame inside (9x1mm is easily bendable) to create compound curves. Label-gun "barbs" every 50 mm on a grid spacing will pin the two polyester sheets at a regular 10mm spacing, and Soudal Fire-resistant Expanding foam injected into the gap. After 2 days foam curing the panels are surprisingly strong and very light.

Road-legal Compliance

It is without any doubt whatsoever entirely your responsibility and yours alone to check your local Laws as to whether the vehicle thay you are about to spend several thousand dollars on may even be driven on roads with other traffic. Even once built it is still solely and exclusively your responsibility to ensure that your hand-built vehicle is safe and legal. It is also unquestionably your sole and exclusive responsibility to ensure that your vehicle which you decided on your own cognizance to construct and then drive is properly Taxed, Insured, and well-maintained.

In the United Kingdom for example a self-built personal-use one-off vehicle under 350 kg may undergo a "Motorcycle Single-Vehicle Approval" test and if deemed safe and road-worthy receive a Q-Plate Registration. It then still also needs Tax, Insurance, and an MOT every year, just like any other Road-legal vehicle.

Other countries however simply flat-out prohibit individuals from driving their own self-built cars on roads with other road-users. There is no road-worthiness test that can be taken: it's just plain illegal to even drive your own hand-built vehicle in that country. You may be able however to use this frame to create a "pedal car" or "pedal assist 4-wheeled electric bicycle", at which point you will need to check your Local Laws regarding e-bikes. There will almost certainly for example be a power limit and a maximum "assist" speed limit.

Do not proceed with a build until you have checked your Local Laws.

Structural Integrity simulation

Checking the geodesic frame integrity was done with a faithful scale model made from straws and hot-glue. Any point that a hard twisting force caused warping easily identified Nodes requiring additional pipes. An actual software simulation has not been carried out because of the complexity, although using ODE either in python or c++ would be relatively straightforward: the entire Vertices and Nodes are all available.

The only thing is that every body panel, by virtue of being part of the structural integrity, would also have to be added and simulated, most likely in basic form of simple triangles connected to Nodes as well as pipes (at regular intervals) as well as to each other.

The advantage of ODE is that it integrates well with libSDL, for real-time 3D display, which would allow the Simulated vehicle to be driven across "terrains" for testing out structural strength. Peeping into the forces on Nodes would allow determining if the vehicle will withstand road usage.

Without such simulation this first prototype is going to just be massively over-engineered. Aixam Ligier Micro-cars from the late 80s and early 90s were thin plastic shells onto which 18x18x1.5mm box steel sub-frames holding the front and rear suspension. Using at least a 2 mm box steel "Ladder" Frame running down the entire vehicle, similar to the Citroen 2CV which was two and a half times heavier than this Category L7e vehicle should give a fair degree of confidence: we will soon find out.

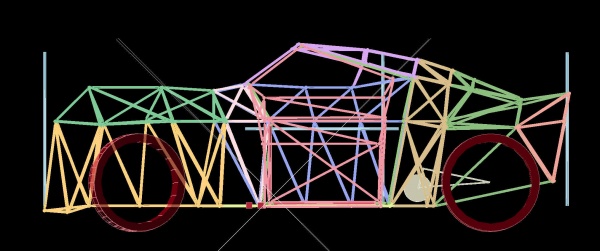

Frame Concept

Blue pipes are 1m measure sticks. Note that the body takes whatever form we would like.

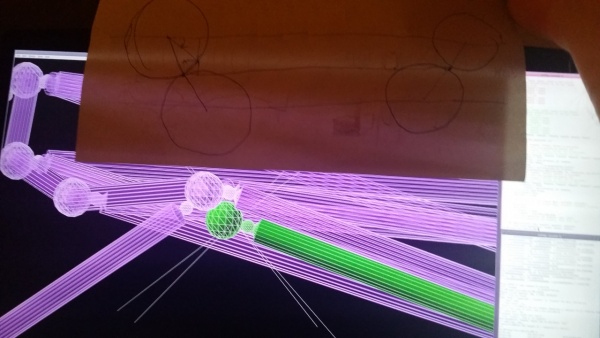

Skeleton frame using 3D-printed software-generated "Nodes" onto which a mixture of 21.5 mm PVC and 8-12 mm bamboo are loosely glued. A second phase involves Kevlar-Resin "wrapping" of the full skeleton, buryong both Nodes and Pipes which were only there as a guide ("former")

CAD Source Code

- git clone http://lkcl.net/vehicle_3d/.git

Build

- Log and pictures - [1]

Prototype 1 Build Procedure

build log on endless sphere https://endless-sphere.com/forums/viewtopic.php?f=34&t=118802&p=1747637#p1747637

build diagrams with Node and pipe numbering can be found here http://lkcl.net/vehicle_3d/pdf/

- Use PVC and bamboo skeleton frame members joined to 3D-printed software-generated Nodes

- Wrap corners in epoxy-impregnated tape

- Wrap the length of tube bodies and the Nodes they are seated on in overlapping epoxy-impregnated tape as needed for additional structural integrity

- For attachment points to metal components, embed metal mounting interface plates/mounts/components in epoxy-impregnated tape just like the corners to attach firmly to the underlying skeleton

- Construct bodywork panel "lattice" frames, cover them in polyester (Dacron), hot-glued to the lattice, punch label-gun barbs through both layers at regular intervals and fill with Fire-resistant Expanding Foam (e.g. Soudal)

Skeleton Frame Phase

BOM

estimated

- 300 metres bamboo canes between 8 to 13 mm diameter, or 300 metres PVC or other pipe or straight sticks up to 13mm. (structural strength is non-critical)

- 200 metres OD 21.5 mm ("Floplast") PVC waste pipe, ID 19.5 mm (again: these are not structural)

- 500 metres 25mm width "Painter's" Masking tape

- 15 20g tubes of rubbery glue (Loctite Extreme, red tube - not Loctite Extreme Epoxy!). do not use hot-glue unless upgrading the 3D-printed nodes to PolyCarb or PETG: PLA deforms at only 60C. do not use strong epoxy or superglue

- 3 tubes Araldite Epoxy

- 5 kg PLA for 3D printing of "Nodes"

- Box of 200 hot-glue sticks

Tools

- 3D printer with 0.8mm nozzle, set layer height of 0.6 mm and 0.2mm "support towers", full coverage. Nodes are complex.

- Usual pliers and files for removing 3D support

- Full wrap eye protection (from high velocity 3D print support material during removal phase: it can get behind your eyes and start scratching)

- Hacksaw and Mitre (90 degree angle cutting)

- Sharp pencil (hard)

- 0.3mm black pen (non-biro) indelible ink for writing on Masking tape

- 1 metre metal ruler and tape measure

- A4 printer

- 25 metres string (for tensioning). garden twine is sufficient.

- Hot-glue gun

- Sharp robust scissors (kitchen scissors sufficient)

Assembly advice

- Measure twice cut once!

- Cutting accuracy on pipes to around +/- 0.15 to 0.2 mm is pretty crucial. The geodesic frame shape amplifies errors which causes cascading problems that require partial disassembly to correct (hence the rubbery glue and masking tape instead of strong rigid epoxy or cyanoacrylate).

- Use the 3D CAD to create 2D screen-shots then draw Node and Pipe numbers on them. As each Node is 3D printed place the same Node number on it, written on masking tape. Print out pipe connectivity listings and cut them into strips that are taped onto the pipe during the cutting phase. Be very strict and patient here because there are 135 Nodes and around 400 pipes to assemble. When (not if) mistakes are made you want to be able to cross-reference the poles and nodes in-situ against the build diagram, and you can't do that unless the in-situ parts are properly identifiable.

- Use the 3D CAD to zoom in onto Nodes in order to get their orientation correct. Sometimes the 2D A4-printed screenshots can be sufficient, but some Nodes are very similar. Make absolutely certain that the angle in all three axes is orientated to within under 2-3 degrees: greater than that results in pipes moving out of position and not seating correctly, and an error-cascade begins. If necessary cut all tape free from all pipes on a node, scrape off the rubbery glue then reglue and retape. Do not attempt to remove a Node from in the middle of an assembly.

- Pipes must be cut dead flat at 90 degrees. Use a file to ensure uneven ends are level: cutting is best done using a Mitre, circular bench saw, or even better a hand-hacksaw held in a cutting jig. It is best to slightly overcut (0.25 to 0.5 mm) then file down, although this can add significantly to build time. Do not attempt to use "undercut" 13 mm OD pipes, or if risking doing so add layers of thin cardboard glued in the seat of the Node (only up to around 2 mm), in order to get its length back up. This trick will not work with the PVC pipes: there is a 19 mm "inset" on the Node which fits inside the 21.5 mm pipe. Undercut pipes are best put aside and used elsewhere in a shorter location.

- Bamboo can be tricky: often it is not dead-straight. Remember that the ends have to be perpendicular ends TO EACH OTHER, not to whatever bend happens to be in the bamboo! If unsure, put the uncut pole aside and select another. If you fail to get the pipe cuts perfectly perpendicular it will result in error-cascades.

- Start from a flat fully-triangulated base of parts then when going vertical locate 3 pipes onto one node and create tetrahedra on the flat base. Use the Node seats as an accurate guide as to direction the pipe needs to go. Once one tetrahedra is created find another right next to it and asssemble that. Do not attempt to assemble from the outside inwards (and try to meet in the middle), work from one side to the other or from the middle to the outside: climbing *inside* the frame to glue-and-tape is very tricky.

- If when it comes to putting in single pipes towards the near-completion of an assembly there is a gap that cannot be bridged by using the masking tape to "pull" the pipe at both ends, use string wrapped carefully between other pipes on the same node at both ends, tie tightly then use another piece of bamboo to prise the twine apart, or use more twine, tying that to other nodes in the same plane to get heavy tension and push the gap shut. Be extra careful as this is where mistakes cascade and get noticed.

- Towards the end as the final poles go in, the redundancy of the bracing will begin to show up any cutting and angle errors, significantly. Do NOT be tempted to change pole lengths from those given in the BOM (except if they were inaccurately cut in the first place).

- Aside from angle orientation errors trust the direction that the pad cones point in. Follow them line-of-sight to their destination Node. If you have the assembly correct up to that point, each new *correctly perpendicular* pole of the correctly-cut length should definitely fit precisely. If the pole is not pointing at its Node seat at the other end, or is not perpendicular, you've made a mistake somewhere.

- Sometimes under the Masking tape the glue will come loose. It is possible to use even more masking tape to "pull" the pole against the Node seat, but eventually it gets unwieldy: that is the point to consider putting twine around instead.

- Always ensure that all poles are attached to their Node seats at all times. Test the assembly regularly by lifting one corner off the ground, carefully, and even more carefully by clamping two Nodes down and deliberately twisting the frame. If assembled rigidly you should see Nodes actually rotating and bamboo poles bending quite significantly. Loose poles (8n need of reattaching) will easily show up with this test as the assembly will be very easy to push about. When all poles are fully attached to all pads, the "twist" test will definitely be hard, and will definitely visibly cause several poles to bow. Do not overdo the twisting.

- The entire frame is extremely light (under 10 kg) at this stage: turn each section upright or upside-down to make access easier, as needed.

Construction order

- Bonnet

- front (turn bonnet over, add front upside-down)

- dashboard (turn front nose-down, add dashboard)

- floor and floor support (keep front nose-down, add floor vertically)

- Driver seat box (on f!oot, after floor detachment from front)

- "Back" box (behind occupants)

- Door sides

- Roof (separate assembly resting on driver box and backbox)

- Rear frame

- Bumper

- Doors

Construct in 4 subassemblies:

- Bonnet, front, dashboard and 1/4 of the floor (assemble whole floor, along with floor support; brace - double-up the bamboo with epoxy - then separate at the footwell line)

- Driver seat-box, "Back" box on floor, door sides, then brace around the Driver seat-box and separate another 1/4 of the floor

- Roof and top section of the "Back box"

- Rear frame continuation of the remaining "Back box" and add bumper

The subassemblies may be tightly taped to each other for checking rigidity and overall assembly correctness. After the Cloth-Resin Phase, bolt-holes will be drilled through, metal spacers inserted and epoxied in, so that the four sub-assemblies can be bolted together with Castle or Nylon lock-nuts.

Rear Section Assembly

The rear is very hard to identify "tetrahedra" and there are curved-arch roofline sections extending behind the two passengers. Follow this procedure for left side then mirror to right:

- CAREFULLY using hot-glue covering just the inner 13mm circle place a bamboo stick dead-upright in the cone. Bear in mind that the Joints are a cone, sphere, cylinder joined together and it is the CONE that points in the direction the stick has to go. You can if you like pre-prepare an 80 mm strip of Masking Tape around the cone which is squashed around the hotglue. Do however keep the cone upright whilst the glue cools and hardens. OVERUSE OF HOTGLUE may melt the PLA so be extra careful: use less then add a second batch if necessary.

- When connecting Joints via Rods make absolutely certain the Nodes are not rotated incorrectly. Use the 3D CAD to get a proper visual feel for orientation if needed, but be accurate to within a few degrees. The hotglue will bend by about 5 degrees but fights it: two or more rods once incorrectly assembled at off-angles require disassembly and starting again. This is harder with hotglue than it is with Loctite Extreme rubbery-glue, so be extra careful and meticulous.

- Add Joint R3 to R4 (see Rear Section build diagram), then R13, then R14, followed by R11 onto R12-R3, and R14 onto R13-R11-R4 in that order

- Assemble NOT USING HOTGLUE but masking-tape and Loctite Extreme Glue (non-resin, rubbery) Rear Bumper B3-B2-B10-B11 at the bare minimum but if preferred include B6-B7 for a full rigid sub-assembly. 21.5 mm Floplast PVC Pipes tend to stick well and stay pointing in the right direction (as long as the PLA has been cleaned up and the PVC cut perfectly perpendicular).

- Do NOT attach B14 or B15 to the B6-7-2-3-10-11 sub-assembly.

- BackBox0/1 only have a single strut to R11 and R14 respectively. DO NOT join any other poles onto R11-13 to BackBox because these are actually part of the (detachable, bolted) Roof Assembly.

- Turn the BackBox Assembly face-down, it is much easier to add the pyramid and tetrahedra coming up next as they sit on their pads under gravity without falling off, prior to affixing (loose masking tape helps keep them roughly positioned)

- In a pyramid with R2 at the top hotglue the four pipes leading to BackBox-14/13/3/4. All four poles can actually be free-floating as long as care is taken.

- Attach the pyramid to the BackBox, noting that as a pyramid not a tetrahedron it will pull and push. Find an edge that pushes, hotglue the OTHER poles, wait for them to dry then prise in the final pole. Do not attempt to use hotglue to "pull" (unless twine is wrapped round, which is quite awkward)

- Attach poles leading to BackBox-14/13 onto R5, free-floating. Add the 21.5mm short section to R5, then attach the tetrahedra to R2 and BB13 and BB14.

- Attach the 21.5mm pipe to R6 but not R5 yet. Hot-glue the two very long poles onto R6 leading to BackBox-9/10, with care, leaving them free-floating but always allow the hotglue to set upright (i.e orientate the entire subassembly so that the pad - and pole - point upwards). Invert the tetrahedra and assemble on R5, BB9 and BB10.

- With the central line now rigid against the BackBox, the roof arch subassembly can be added. Hotglue R11 to BB14 and BB0, and R14 to BB15 and BB1. Add R4 towards BB15 and R3 towards B10. leave all pipes freestanding, bear in mind that the longer rods go to the same Node as the two down-pointing short ones.

- Drop the roof arch in place and hotglue all pads. The assembly will still rock sideways: it is an open arch.

- Connect R3 to R2 and R5: this will stiffen up the roof arch, but beware any cutting inaccuracies and Node angle inaccuracies, they will show up at this point (twine helps put poles under compression, whilst hotglue sets).

- Rear light / bumper sub-assembly can be added: B3 to R3-R4, B2 to R4-R2, B10 to BackBox14 should be sufficient to get started, first hotgluing bamboo rods carefully free-floating, leaving them unattached initially, position the sub-assembly under gravity.

- Add 21.5 mm B14 to B6-B10 using Loctite Extreme and masking tape, and let it set before moving on, checking that the UNATTACHED sub-assembly pipes (to R3, R4, R2 and BB14) are the correct length from their pads. Expect there to be some differences: first hotglue those poles that are a fraction AWAY from their pad (shift the other poles which are "too long" off-pad carefully) then once the hotglue sets fully bring in each "too long" pole one at a time. Make absolutely certain that the pole is definitely perpendicular to its pad, and if there is ever a gap greater than 5-6 mm STOP and re-check pole numbering and length. As each pole is hotglued expect the whole sub-frame to begin shifting about.

The remaining poles can be connected up with care: bamboo can if necessary be bent somewhat to get it into position (or a section broken off of the pad's wall), and if 6-10 mm bamboo poles are used rather than the full 13 mm it is possible to get glue onto the full pad surface (including under the pole's end) by shifting the pole around within its seat. If using hot-glue do this quickly and be prepared to use short squirts then follow up with a second layer.

Towards the end of the assembly process putting some rods under tension caused other rods to pull free from their pad. More twine was needed to put those back under compression, and eventually everything settled, although a lot of force was needed in some cases (doubled-up twine). This occurred on the other assemblies so it was not a surprise.

Kevlar/Cloth-Resin phase

Adequate ventilation is critical at this phase. Epoxy resins can give off fumes. Make absolutely certain to read and follow all safety guidelines. This is entirely your responsibility.

There are two main tasks here:

- cover all Nodes (just like in Bamboo Bike Club and Calfee Design)

- cover all Pipes. The pipes are in NO WAY structural: they are a guide.

All pipes and all Nodes need to be entirely cased in Cloth-Resin multiple layer wraps, fully interleaved. This is unlike in Bamboo Bikes which utilise the strength of the bamboo itself: here we use the bamboo (and PVC) as a former for the Kevlar/cloth. Instructions on how to do Cloth-Epoxy wrapping can be found from many sources.

BOM:

- Fire-resistant Epoxy (FR4) available from MBFG.co.uk

- Sicomin SR5550/SD5505 (fast hardener) available from MBFG

- 1414 (4mm weave/weft) Kevlar cloth

- Flax, hemp, or hessian (thick coarse linen)

- Kevlar "strip" 50mm wide

- Scrap paper

- Masking tape 25mm wide

Tools:

- stippling brushes (QTY 50)

- Protective clothing, face masks, rubber gloves.

- Mixing and measuring containers

- Mixing sticks

- Floor protective covering

- Sharp scissors

Recommendations:

- The assembly will start to get heavy, and may cause the collapse of un-epoxied Nodes that are face-down on the floor, particularly those with bamboo poles instead of Floplast. Consider a support jig or ensure that all Nodes are properly glued-up. The ones in contact with the floor were only using Loctite Extreme (rubbery), not hot-glue, and cleatly not enough of either.

- Pack out any large gaps especially around 21.5 mm Node Seats with crumpled paper covered by Masking tape. Create a full sealed wrap with Masking tape around the Node so that resin is not wasted dripping inside. If this is not done a large amount of Kevlar and resin could be wasted filling up gaps, increasing overall weight.

- The packing should be done with the following thoughts in mind: "when wrapping strips of cloth, firstly will the cloth bunch and crumple at all, and secondly will it create an air-bubble if stretched taut?". These two questions if answered with a scrap piece of cloth as a tester will ensure cloth-resin-cloth contact on all layers.

- For 21.5mm PVC pipes, pre-prepare kevlar cloth strips 80-90 mm wide with "tails" at each end anywhere between 80 mm and 120 mm which will be used to wrap around the Node and Pipes at the other end. Split just before reaching the Node, so that the "tails" do not end up with airgaps on branching out.

- For bamboo poles similarly but under 50 mm wide strips (which will still wrap at least twice in some cases).

- Alternate between wrapping pipes and wrapping Nodes (with 50 mm Kevlar strips). Although the "tails" from the cloth wrapped around the pipe should join to other pipes and create good structural bonding in some cases it will be evident that the cross-over is inadequate. Use several layered strips appx 18in by 50 mm to create adequate bonding between pipes.

- The Kevlar 50 mm strip from MBFG is expensive (and really high quality), so use very sparingly. Try to use long tails as much as possible, and only if those really will not adhere (concave indentation) use an appx 6 in or suitable length of 50 mm strip, laid at right-angles, to get the tails to behave. Do not wait for the resin to dry before doing this! Therefore, have a few 6in x 50 mm strips pre-cut.

- There are extremely cheap packs of 50 1in brushes on Amazon (under USD 10) which can be trimmed to 15 mm and used for "stippling". Stippling is best done when the resin has reached a gel-like consistency: at this point the fibres of the cloth beginning sticking to the brush, become coated with resin, and "string out" (like unprocessed cotton wool). This results in a chemical reaction between cloth and resin that increases strength and adhesion between layers.

- Discard the brush on each batch: at $0.15 per brush it is not worth recovering (of course if living in an isolated self-contained or Permaculture environment disregard this advice entirely).

Videos

https://www.youtube.com/playlist?list=PLBtNqZjUZB81KyRPnMHSmX-vF8i7h5kcA