OSE Shop 2011

Jump to navigation

Jump to search

Main > Housing and construction

A 12 cell (16'x16') workshop for prototyping and production runs of open source ecology machines

Design Model

Sketchup model: [[1]]

Embed:

Notes for model update

- shift roof configuration to use more standard boxes

- remove lost boards

- create tie/bearing detail for column to beam interface

- create tie detail for roof beams to roof boxes

- create detail window frame

- create rebar plan

- show possible insulated infill plan

- show possible uninsulated infill plan (shed may do)

- propose alternate machine room on storage shed

- propose alternate extended front office/sanitary/planning space

- propose alternate rotate to face south

Design feedback from a Production/Floor designer

Outline extracted from a conversation between David Ihnen (design proposer) and David Dalton of Kansas City, a professional production floor layout contact.

- Shop Design:

- likes the roof angles

- Chlerestory brings lots of light in, that is good

- Gantry is good

- Biggest problem: Headspace.

- low cieling feels claustrophobic, is not so nice to work in.

- extra cieling space can be used to hang racks and store materials

- too little overhead space and you can't do anything about it

- Gantry system needs space for hoist - it would lucky to be able to lift a lifetrac off the ground at its current height of 9 feet at top.

- Storage space

- A nearby building - suggest the gantry extends to a shed to the north, where production materials will be stored. Gantry allows easy retrieval without ground level improvements (concrete).

- Compressed Air.

- Compressed air is critically important for cleanup, blowing bits out of crevasses better than about anything.

- Compressed air tools are bulletproof - electric ones wear out quickly,compressed air tools do not.

- Compressed air tools are powerful and buffered - no matter how slowly compression is generated, maximal power is available at the moment it is needed.

- Compressed air does not require electricity - either directly off of wind power (good idea!) or steam, or gas engine, or lister - whatever.

- Take the time to distribute your compressed air around the shop

- keep your requirement for flexi-hoses short, 4 inner columns good location for them

- Gantry.

- Excellent materials handling solution

- makes moving heavy things, lifting them up, etc far easier - when dealing with heavy things, that hoist can make a world of difference.

- Transport from storage to production floor is easy and smooth

- Tiger Stop

- All About Tigerstops: [[2]]

- Example used model on ebay [[3]] - sold for $4500

- Any sort of production needs a length-measuring table with adustable stops for efficiency

- tiger stop style table will accelerate production massively - 30-40% easily.

- fully automatic tiger stop style table will accelerate parts cutting even more

- is a single-axis cnc - not difficult to arduino and construct ourselves!

- consider a double ended table, one end bandsaw, one end mitre saw

- HIGH USE TOOL - as the most frequently useful tools in the shop, it should be centrally located

- Can also be equipped with a drill press for automating positioning of materials to be drilled!

- The Robots.

- Put robots in range of equipment

- consider flexibility - hard-mounted robot gets in the way when not being used

- robots are useful only when actively programmed.

- board mill->robot->rack->robot->cnc->robot->rack workflow could automatically create wooden parts

- robot combined with tiger stop type table could automate much workflow of creating metal parts too

- Table Saw

- You ABSOLUTELY DO want a table saw if you're doing wood fabrication

- a large one - or don't bother

- can double as workbench with blade retracted

- Dust Collection

- Install a dust collection system if you're going to be routing and/or cutting much wood. Recycle the chips for fuel, and the fine sawdust is even more useful.

- use a two stage filtration chamber to separate - easy to build

- Curtains

- Put BLACK curtains around the welding areas.

- Welding flash causes eye damage, even indirectly

- Welding exposure is bright UV, impacts more than merely the eyes of those around, radiation burns too.

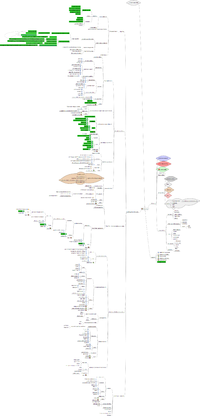

Construction Plan Mindmap

Full size here:[[4]]

Actual Mindmap file here (created with freemind) [[5]]

Cost Estimates