Foundry

Jump to navigation

Jump to search

Introduction

- Steel melts at around 2500F, 1350C, or slightly below iron

- Iron melting point - 1540C, 1811K, 2800F

- Cast iron melting point - 1150-1200C, about 300C lower than pure iron

- From [1]:

- Seel is iron and up to 2.0% carbon without any other alloying elements

- Above 2.0% C we are dealing with cast iron

- The steel melting point varies between 1540°C and 1400°C, gradually declining with increasing carbon content.

Foundries

- College foundry, 100 lb steel or iron, 100 kW induction furnace - [2]

- 200 lb dipout furnace for sale - [3]

- 3000F furnace, 750 lb per hour after first heat - electric with 2 electrodes - [4]

- Arc furnace, 175kW, 700 lb/hour - [5]

- Induction Furnace - 40 kW - http://www.ufes.com/index.php?n=Foundry.InductothermInductionFurnaceModel40-96

- ARC, 53kW, 560 lb - [6]

- Induction 4000 lb for 100kW, or 1000 lb for 25 kW? - [7]

Plans

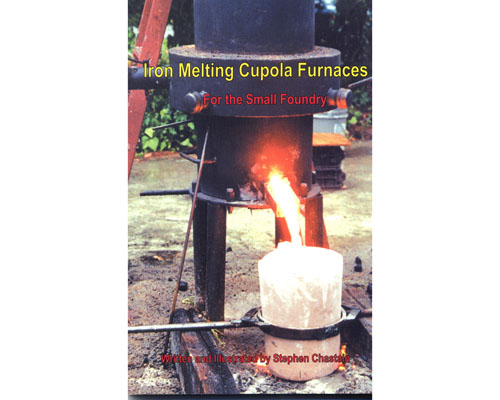

- Plans for a 330 lb/hour iron melting foundry - [8]:

Books

- Google Book, Maximum Production in Machine-shop and Foundry - 150 lb shots in 1911 foundry took 3.5 hours - with noted low production - [9]