Cold Saw/Understand2

Starting the Design with the Right Focus

How the blade will be rotated and how the material will be held are the 2 major considerations.

Following that, how to combine the rotation and holding mechanism into a single assembly while allowing the blade to move into and swivel at an angle to the material.

Rotating the Blade

Cold Saw rotation must let the material be chipped away. The rotation speed must be low so as to avoid producing dust. The torque must be high so as to ensure a consistent cutting process without stalling (the rotation stopping because not enough power was transmitted to the blade teeth to chip away the next layer of material).

Conventionally, Cold Saws use an AC motor (alternating current) that rotates at extremely high speeds with low torque. A multi-stage gearbox (multi-stage means a lot of gear reduction steps) is typically used to change the kinetic power output into low speed and high torque. Controlling the speed of an AC motor at a constant torque involves relatively complex electronics.

Hydraulic motors rotate at low speeds with exceptionally high torque; as such, no gearbox is required. Controlling the speed of a hydraulic motor at a constant torque involves a simple hydraulic flow splitter.

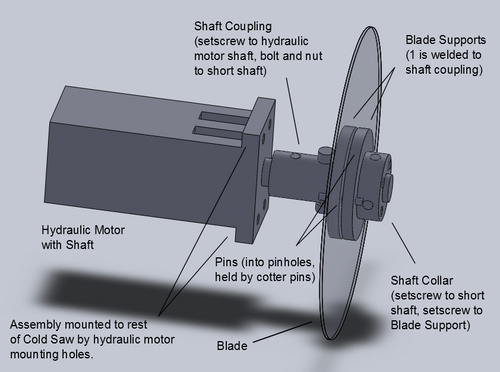

The Cold Saw's blade rotation will be powered by a hydraulic motor because hydraulic motors require no gear reduction and are simpler to control at constant torque than AC motors.

Direct Drive

Rotation Parts

Mount Disc to be removed