Sawmill Design 2

Jump to navigation

Jump to search

Main > Housing > Construction > Sawmill

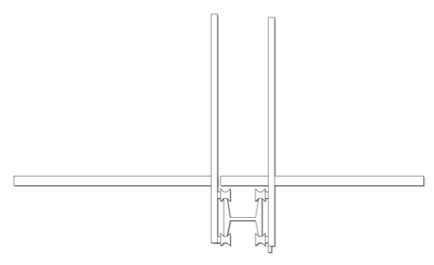

What if we use steel sections to eliminane need for building a track?

10x4" I-beams in the 20 lb/ft range are available - see PDF page 132 in Structural Steel Sections

Use 30" hydraulic cylinders for y and z motion in a cantilevered configuration along the steel section x axis. Absolute simplest design is obtained, if 40 and 20 hp hydraulic motors are used for a 20" and 10" sawmill blade.

High performance, 60 hp sawmill at about $1000 in parts. Another breakthrough, as similar power costs at least $25k.

Calculations

[Hydraulic motor power] = torque (in-lb)*RPM/63k

- Take 5000 RPM, 166 in-lb motor for 13 hp

- take larger motor for 30 hp at 3500 RPM - at $250