Steam Engine Specifications/Indicator Diagrams

Main > Energy > Steam Engine

Text taken from Steam Engineering: A Text Book by William R. King

Collecting Indicator Data

Theoretical work diagrams are balanced by taking actual readings from a working steam engine via a device called an engine indicator. This device causes a pen to move as pressure in the cylinder rises or falls. The device is a delicate construct of springs and linkages so as to scale the pressure range to a graphical output.

An alternative approach might be to buy a digital pressure sensor and interface it to a data gathering computer. This has the advantage of being able to collect all data and average the results. It can be also be trigger to collect data once the engine has reached operating speed and temperature.

See pressure sensor in Wikipedia [1] for types of sensors.

Indicator Diagram Information

The main value of the indicator diagram is that it shows the mean effective pressure exerted on the piston during an entire engine cycle and thus shows the power of the engine. It also shows information about the engine's design and performance including:

- Valve Performance

- Properly set

- Admission of steam is late or early

- Initial pressure is unduly lower than the boiler pressure

- Degree to which pressure is maintained up to the cutoff point

- Point in the stroke at which steam is cutoff and if the cutoff is sharp or gradual.

- Point in the stroke where release takes place and steam pressure at that point.

- Exhaust Characteristics

- Amount of back pressure opposed to the exhaust

- Point that exhaust is closed

- Amount of compression at the end of the stroke

- Whether the steam ports are of adequate size

- Wheater the valve or piston leaks

- Appropriate amount of steam is consumed in a given time

- Several vital features concerning the balance of the engine

Indicator Diagram Analysis

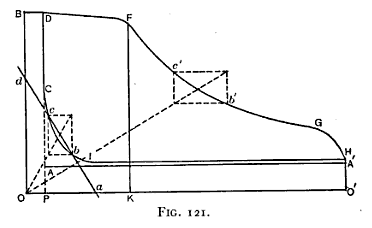

Once the indicator diagram is plotted, a diagram similar to the figure CDFGHI is produced. The lines of this diagram and certain points have specific names, described below.

The Engine Cycle

Immediately on admission of steam, the admission line CD is traced, its height above the atmospheric line, measured to scale, showing the initial gauge pressure of the steam admitted to the engine cylinder.

The engine piston starting on it's stroke, the steam line DF is traced during the time steam is being admitted into the engine cylinder.

At the point of cut-off, F, the valve closes, preventing any further admission of steam inot the cylinder. The exact point of cut-off, when effected by the valve, is difficult to locate, owing to the fall of steam pressure due tot he gradual closing of the port by the valve, shown by the curving of the diagram about F.

The expansion curve FG represents the fall in pressure of the steam confined in the cylinder after cut-off in forcing the piston to the end of the stroke.

A G, the point of release, the valve opens to the exhaust (or exhaust vent is reached), releasing the steam from the cylinder. The higher the rotational speed of the engine the earlier the steam must be released to enable it's pressure to fall to that of the back pressure before the piston commences it's return stroke (hence the use of vacuum on the exhaust vent in the White Cliff's engine).

The exhaust line GH is traced in the interval between release and the end of the stroke, the pressure falling rapidly to that of the back pressure opposed to the exhaust.

In order that the exhaust steam may flow from the cylinder of a condensing engine to the condenser, or into the atmosphere from the cylinder of a non-condensing engine, the actual back pressure must be greater than atmospheric pressure in the other and this excess of pressure depends largely upon the freedom of passage fro the exhaust steam from the cylinder to the condenser or atmosphere. The release of steam from 88 to 90 per cent of the stroke assists materially in the freedom of the exhaust; this is necessary in a condensing engine to insure a nearly complete vacuum when the piston starts on its return stroke and with a non-condensing engine it enables the exhaust steam to begin it's flow into the atmosphere before the return stroke commences.

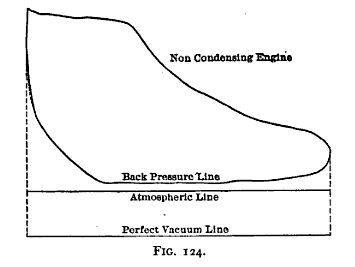

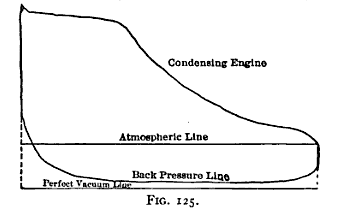

The back-pressure line HI shows the pressure opposed to the piston on its return stroke. In non-condensing engines this line is slightly above the atmospheric line and in condensing engines it is below the atmospheric line a distance corresponding to the vacuum obtained; but in either case it is back pressure. Vacuum is expressed in inches of mercury and since one cubic inch of mercury weights 0.491 pound, the inches of vacuum multiplied by 0.491 will give the pressure equivalent to the vacuum in PSI.

A I, the point of exhaust closure, the valve closes the port to the exhaust (or the exhaust vent is covered) and the compression of the steam trapped in the cylinder begins.

The compression curve IC represents the rise in pressure of the trapped steam due to it's compression into the clearance space by the piston. The advancing piston compresses the steam, its pressure rising to some point C where the valve opens to lead, the pressure rising suddenly to D and a new stroke commences.

Locating the Vacuum Line

For the study of the diagram and for computations involving pressures, it is necessary to locate the vacuum line OO', or line of no pressure, from which all pressures must be measured to make them absolute. The vacuum line is parallel to the atmospheric line and at a distance below ti equal to the pressure of the atmosphere measured scaled appropriately to the diagram. The average atmospheric pressure is 14.7 pounds, but this will vary by altitude above sea level and the weather.

Locating the Clearance Line

Of equal importance to the vacuum line in computations involving the indicator diagram is the clearance line OB. it is perpendicular to the atmospheric line and at a distance from the end of the diagram equal to the same percentage of the length of the diagram that the volume of the clearance space of the cylinder bears to the volume displaced by the piston.

The diagrams from the two ends of the cylinder should be taken simultaneously if two indicators are used,or one immediately after the other if only one be used (this refers to continuous flow engines vs. uniflow engines).

Theoretical Differences

Diagrams taken from the engines of proper design and adjustment do not differ very materially from the theoretical diagram, but it requires careful study and discriminating judgment to make proper use of the information presented by them, a fact that may be appreciated when it is considered that the only absolute information a diagram gives is the varying pressure of the steam in the cylinder.

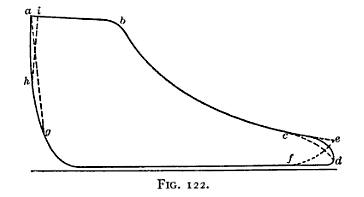

The full-line diagram of this figure would indicate a very satisfactory performance. The gradual fall in pressure in the steam line from a to b indicates wire-drawing, the technical name given to the reduction pressure due to friction in the passages. Improper design of the ports may cause this loss to be excessive.

The dotted lines illustrate some possible defects of an engine which would readily be detected by the indicator. The line cd would show that the release was too early and the life ef that it was too late; the inclination of the admission line to the left at ga would show the lead to be too great and its inclination to the right at hi would show insufficient lead.

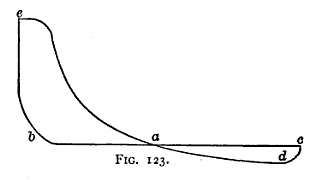

Should a diagram be looped (as in the illustration above), the area adc represents a negative work and in obtaining the mean pressure from such a diagram, the lengths of the ordinates included in the loop must be subtracted from the total length of those within the area eba. A loop like this is the result of excessive expansion. At the point a, where the expansion curve crosses the back-pressure line, it is evident that the pressures on both sides of the piston are equal and a cut-off which would occasion an expansion so excessive as to reduce the steam pressure to a point below the back pressure opposed to the piston would be manifestly too early. The theoretical limit of expansion is such that the terminal pressure should be just equal to the back pressure, but practical considerations make it exceed this, varying from 24 to 28 pounds absolute in non-condensing engines and from 10 to 15 pounds in condensing engines. In actual practice, a loop in the diagram would very likely indicate that the engine was overloaded.

It has been shown that the mechanical work is produced by a force working through a distance. In the case of any gas working within a cylinder against a piston, the force will be the mean value of the pressure of the gas multiplied by the area of the piston and the distance will be the stroke of the piston. In order that the work may be expressed in food pounds, the force must be expressed in pounds and the distance in feet. it is seen then that the area of an indicator diagram is the measure of the work performed on once side of the piston during one revolution; for this area is the product of the length of the mean ordinate of the diagram and the length of the diagram, the first factor expressing the mean effective pressure on the piston in pounds per square inch and the second factor expressing the length of the stroke in feet.

Mean Effective Pressure

Method of Ordinates

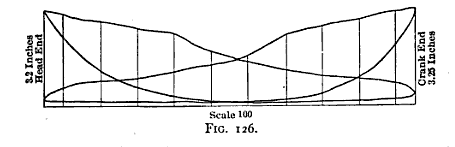

To obtain the mean effective pressure from the indicator diagram by the method of ordinates, erect perpendiculars to the atmospheric line touching the extreme ends of the diagram. Divide the space between these perpendiculars into ten equal parts and at the middle points between these divisions erect ordinates to the diagram perpendicular to the atmospheric line. The first and last of the ordinates will be 1/20 of the length of the diagram from the ends and the common interval between the ordinates will be 1/10 of the length of the diagram. One-tenth of the sum of the lengths of the ordinates will be the length of the mean ordinate and the length of the mean ordinate multiplied by the scale of the indicator spring gives the mean effective pressure on the piston throughout the stroke in pounds per square inch.

This diagram was taken from a high speed engine of the Harrisburg type. The sum of the lengths of the ordinates of the diagrams from the two ends of the cylinder is 3.2 inches and 3.25 inches and the scale of the indicator spring is 100 pounds to the inch. Then for one revolution:

M.E.P. = (100(3.20+3.25))/20 = 32.25 pounds.

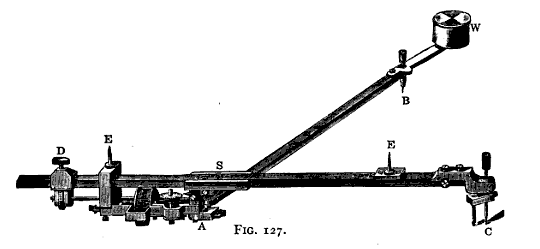

Method of the Planimeter

The planimeter is an instrument designed primarily to measure the areas of plan figures. its application to finding the area of an indicator diagram, from which the length of the mean ordinate is readily obtained, enables the main effective pressure to be found more quickly and accurately than by the method of ordinates.

The instrument most commonly used is some form of the polar planimeter of Amsler. Here is one manufactured by Keuffle and Esser (K&E):

(a detailed description of the planimeter is provided)

The perimeter of the indicator diagram is traced by the device and the result is modified by the indicator diagram scale. Given the lack of such a device, the exact operation is omitted here. See original text on pgs 235-239 for detailed instructions.

Computational Method

Given a set of pressure readings collected by a digital pressure sensor, the Method of Ordinates could be expressed as an algorithm implemented in a software function that would calculate the mean effective pressure. M.E.P. and engine power should be calculated and included in the output plot of a digitally created indicator diagram.

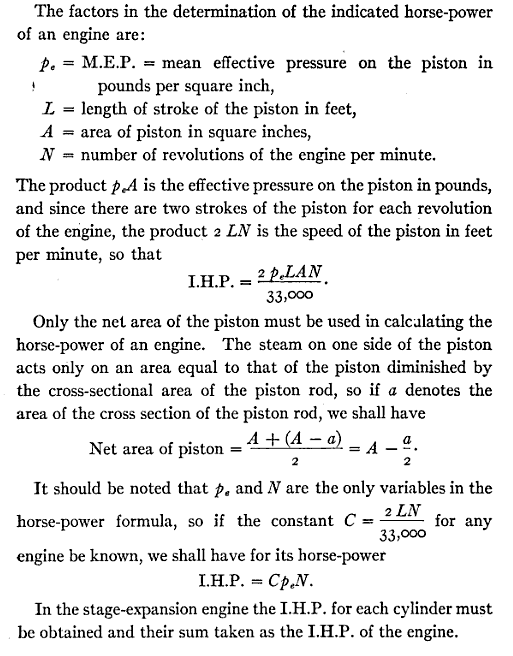

Engine Power

Having found from the indicator diagram the mean effective pressure in pounds per square inch acting on the engine piston throughout one revolution, the product of this pressure and the area of the piston in square inches will be the total pressure acting on the piston in pounds. If this total pressure be multiplied by the distance in feet moved through the piston in one minute, the product will be an expression in foot-pounds of the work performed by the engine in a minute and this product, divided by 30,000 will be the horse-power of the engine.

The mean effective pressure having been found from the indicator diagram, the power thus obtained is called the indicated horse-power, usually denoted by the initials I.H.P. and is equal to the useful work delivered by the engine and the work expended in overcoming the friction of the engine itself.

Clearance

The volume of all the space between the piston when at the end of its stroke and the value face is known as clearance of the engine. Clearance is expressed in terms of percentage of the volume proper of the cylinder, that is, of the volume displaced by the piston in one stroke. The amount of clearance varies in the different types of engines. In engines of slow speed and long stroke, the variation is from 2% to 4%; in engines of high rotational speed and short stroke, it may be as much as 8%; an din maritime engines a clearance of 15% is no uncommon.

Clearance can be measured from an indicator diagram (see text).

The clearance space at each end of the cylinder must be filled with steam from each revolution of the engine (in a continuous flow engine) and this steam must come from the boiler or from the steam left in the cylinder by the exhaust closure or from both. since the piston does not traverse the clearance space, the clearance steam performs no initial work; it does no work during the period of admission, but after cut-off its effect is to raise the pressure during the expansion and thus increase the area of the expansion part of the diagram. If there were neither expansion nor compression, the clearance steam would perform no work at all and would be a total loss in the exhaust. On the other hand, if the expansion curve were carried down to the back pressure and the compression curve carried up to the initial pressure, there would be absolutely no loss from clearance. Such conditions are never realized in practice, there for there is always a loss from clearance and this loss is greater as the clearance is proportionally large.

One effect of cushioning is that it reduced the loss from waste of steam in the clearance space, but its most important effect is that it provides for smooth running of the engine by preventing shocks at the end of the stroke. it is especially desirable that the diagram of an engine of high rotational speed have its compression curve well rounded.

Clearance in the engine occasions a loss when the consumption of steam per unit of power is considered, but there are practical considerations which make its existence highly desirable, if not necessary. the clearance space between the piston and the cylinder head, when the piston is at the end of its stroke, give space for the variable amount of water which is always present in a cylinder and doubtless prevents serious accidents which might otherwise occur.

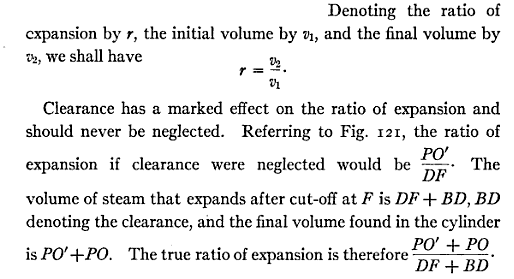

Ratio of Expansion

The ratio of expansion of the steam used in an engine is he quotient derived from dividing the final volume of steam found in the cylinder by he initial volume admitted. By initial volume is meant the volume of steam admitted to the cylinder up to the point of cut-off, plus the clearance volume, and by the final volume is meant the volume of the volume of the cylinder, plus the clearance volume.

Since the cross-section area of the cylinder is uniform, the volume displaced by the piston at any point is directly proportional to the fractional part of the stroke completed at the point, so that the volumes may be represented by their corresponding fractions of stroke. In like manner, the clearance volume, when divided by the cross-section area of the cylinder, will be expressed as fractional part of the stroke. Then, if we denote the full stroke of the piston by unity, it may also represent the volume displaced by the piston in one stroke, in which case the fraction of the stroke denoting the cut-off will represent the volume displaced up to the point of cut-off.

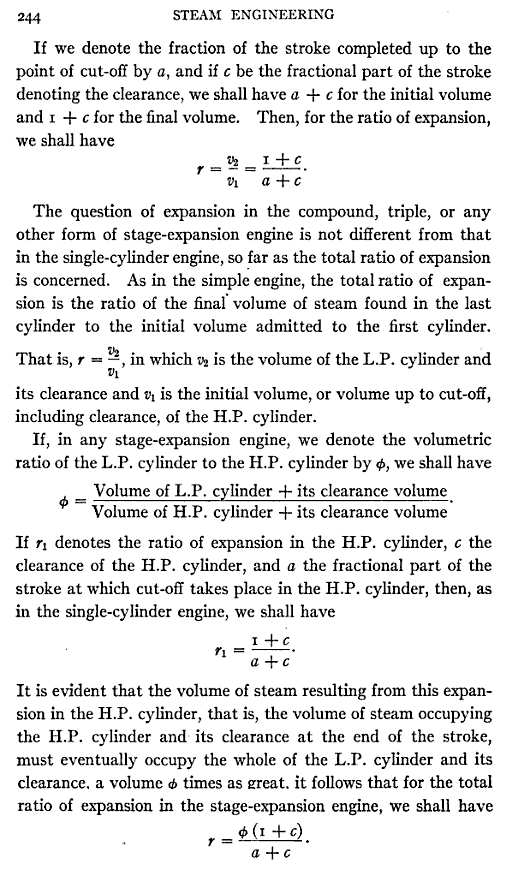

Neither the volume of the receiver nor the cut-off in the L.P. cylinder has anything to do with the question of the total ratio of expansion in stage-expansion engines. The effect of the receiver is to make the initial pressure lower in the L.P. cylinder than it otherwise would be if the exhaust from the H.P. to the L.P. cylinder were direct, and this reduction in pressure is due to the drop occasioned by the unrestricted expansion of the steam when it enters the receiver space. The receiver only plays the part of a large clearance space.

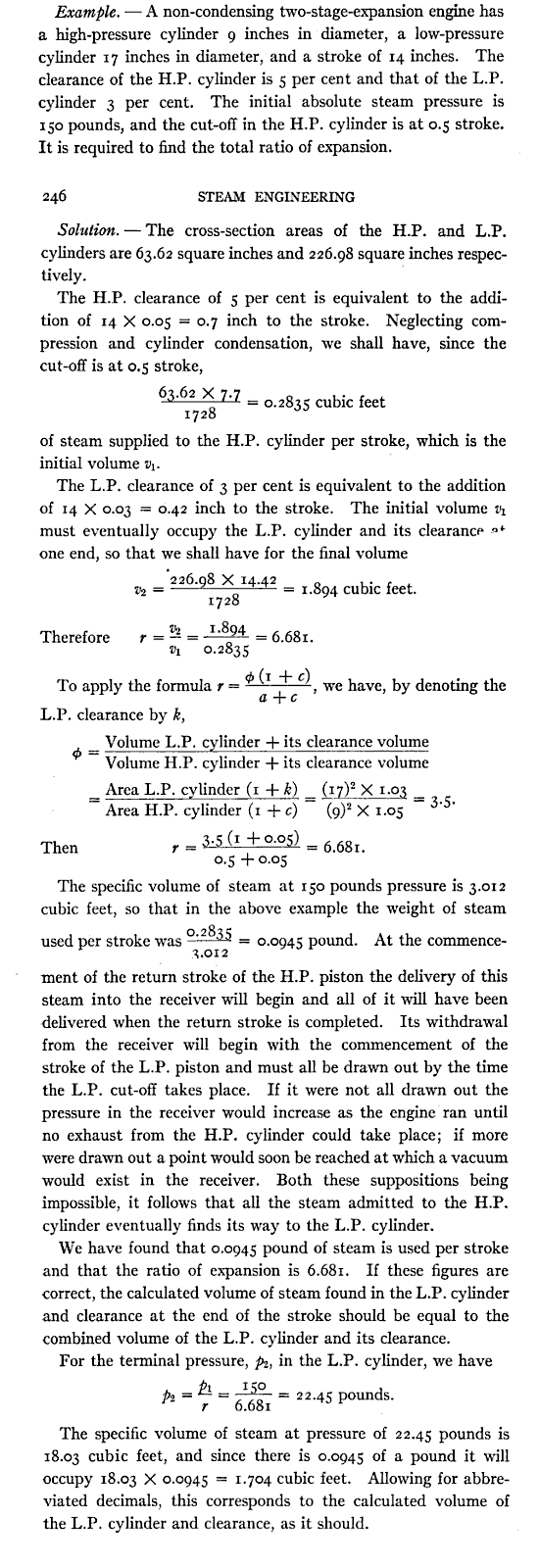

The low-pressure cut-off will increase the receiver pressure and therefore the power of the L.P. Cylinder, as has been shown, and this increase in the receiver pressure increases the back pressure on the piston of the next proceeding cylinder in the expansion and therefore decreases the power of that cylinder. So it is seen that the function of the L.P. cut-off is to equalize the power between the cylinders and has nothing to do with the total ratio of expansion. Whether the steam is or is not cut off in the L.P. Cylinder, the same weight of steam must find its way into that cylinder at each stroke, and if, by means of the cut-off, a less space be provided the reception of the steam, the pressure will increase accordingly. The question of expansion in stage-expansion engines may be understood better with the aid of an example.

In the above calculations the effect of compression has been neglected, but the only way this could affect the question would be to reduce slightly the quantity of steam withdrawn from he boiler at each stroke, which may be regarded as virtually increasing very slightly the ratio of expansion, because a less weight of fresh steam would be used each stroke.

The effect of cylinder condensation has also bee neglected, but this also would occasion a virtual augmentation of the ration of expansion, because a smaller weight of steam than that delivered to the H.P. cylinder would be found in the L.P. cylinder at the end of its stroke.