High Temperature Heated Enclosure

Concept for High Temperature 3D Printer Build Chambers

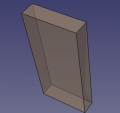

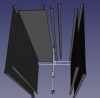

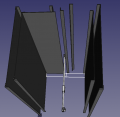

By separating all electronics and including only the extruder nozzle in the working volume - a heated chamber can be built for up to any required temperature up to the melting point of the build plate. The key is a stationary enclosure and a moving lid attached to the extrudsr, with a thermal seal between the chamber and the lid.

CAD - Small

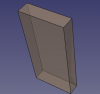

Fire Brick - FreeCAD -File:Firebrick.fcstd

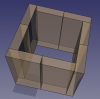

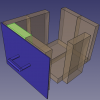

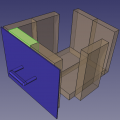

Fire Brick Assembly. - FreeCAD -File:Firebrickassy.fcstd

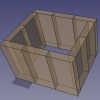

Fire Bricks and Door. - FreeCAD -File:Firebricksanddoor.fcstd

PEI Heat Shield - FreeCAD -File:PEIHeatshield.fcstd

CAD - Large

Large Heated Chamber - FreeCAD -File:Largeheatedchamber.fcstd

BOM

- Fire Brick - build around common available

- Fiberglass / carbon fiber blanket for the top face of the enclosure

- Techno Gewebe - 30€/sqm - [6]

Working Document

Communications

Response

Hello Marcin,

I thought this patent expired at the end of this year but maybe I'm thinking of another one Stratasys holds. That, or the patent expiration was delayed somehow.

We are working on an enclosed printer, Brizo. We expect the build chamber to reach higher temperatures than we would expect from a non-enclosed printer. However, in our preliminary tests using a large AC powered heated bed and four tool heads all heating at once in an insulated enclosure we top at 60C for the build chamber temperature. This is well below the claim:

8. The apparatus of claim 1, wherein the build chamber is heated to a temperature greater than 150° C.

We are already printing some high temp materials like PEEK and PEKK on a modified Mini 2 with just an acrylic enclosure, this testing separate from the insulated enclosure test. Early tests are looking decent but we are early in so we're not completely certain yet if the 60C build chamber temperature will be adequate.

As you noted, we are not planning on blocking the gantry system with a heat barrier. We're finding components such as linear bushings, bearings, and motors that can withstand temps above 60C. This new printer will also be heavily reliant on machined parts rather than printed ABS parts as in our other printers. The electronics controller will be outside the heat chamber.

I think we're on track to be able to get high temperature printing without concern of the Stratasys patent. I'll keep you updated if we run into any road blocks in our current plan.

Question

Hi Steven (from Aleph Objects),

We're looking into heated chambers - I remember you mentioned you will have an enclosure for you next generation machines.

How are you negotiating the Stratasys heated enclosure patent? By not going to high temp? You guys are just doing an integrated enclosure, not a high temp build chamber, right?

Notes here on the relevant patent- https://wiki.opensourceecology.org/wiki/Heated_Build_Chamber_Patents

My analysis of the situation is that Stratasys is protecting their concept of a bellows - ie, a deformable heat barrier. Thus, a different system for high temp would be allowed. We want to do a simple stiff barrier attached to the extruder, diagram on the wiki.

MJ