Jeff Moe

Intro

Jeff Moe is the founder of Lulzbot.com

I'd like to clarify why I like to rave about LulzBot.com, the libre 3D Printer company. I just visited Jeff Moe, CEO and long-time True Fan. Jeff is the next generation of entrepreneur - the open source industrialist - like the robber baron of yesterday - but updated for the open source ethic of the digital age - what we call Distributive Enterprise at OSE. That means open hardware blueprints, but also open enterprise blueprints. Such as workflow and layout schematics of his production line. Documentation of enterprise-level management in OpenERP. Full sourcing information so you can build yourself. Organizational Gantt charts, etc. I know of no other company in the world that has reached so far on the open enterprise level. This is hope and inspiration for the world - the open source economy coming to life. Jeff is providing an example for the world to learn from, and at 300% growth rate, he is one to watch out for. - MJ 2/10/14

http://www.fsf.org/resources/hw/endorsement/respects-your-freedom

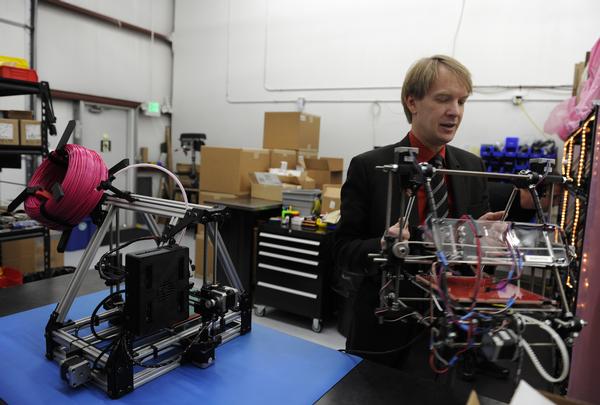

Caption: Jeff Moe in the early days of Lulzbot with the AO100 printers.

History

- After a bout of successful expansion, Lulzbot was sold in what was apparently a distressed sale in late 2019 - [1]

Lulzbot Documentation

Right now, we just have a huge ftp/rsync archive, like this:

http://download.lulzbot.com/AO-101/

rsync://rsync.lulzbot.com/lulzbot/AO-101/

That is currently 990 megs of data. That includes software as well--we wanted the full stack. Not just the hardware, but the software we know works well with that hardware.

We also release designs for machines we haven't released for sale. You can see an example of that here:

http://devel.lulzbot.com/TK-0/

The TK-0's files have all been redrawn in FreeCAD, which is now the master repository. So not just are the files free, but the software to use the files is also free.

Supersizing a 3D Printer

Your manual for Lulzbot AO100 is awesome, great work.

Thanks. I've hired Gary Hodgson ( http://garyhodgson.com/ ) to work on a manual for Slic3r too.

It sounds like we would need to go to 1000x500x500 to print car bodies like the Urbee 2:

That's quite huge for printing.

http://opensourceecology.org/wiki/Large_Scale_3D_Printers

I talked to Jim Kor of Urbee about 1 year ago and he wasn't interested in going open source. OSE is considering building Urbee style design, based on WikiSpeed, our collaborator - to produce our open source car.

WikiSpeed looks cool, but I don't see the code. I just emailed them about getting that and a car. Urbee doesn't interest me unless they open it up.

How would you feel about collaborating on a larger scale 3D printer and building a car body?

This sounds great, but I only have so many engineers and they are pretty busy of course. We'd be happy to work on it though--provide direction, parts, etc.

Are you interested in a Jam to do this, say we invite 50 engineers to a location for design/prototyping work?

Sounds interesting.

Are you considering significant product line expansion?

We have about 200 products we sell now, if you include motors, power supplies, filaments, printers, etc. We are always adding new parts. We're selling a new machine in a couple months which can do about 300mm x 300mm x 250mm (the TK-0). We also have in the works a filament extruder (a machine that makes filament from raw material) in the works. It is based on the Lyman Filament extruder.

On the printer:

1. What are the limiting structural factors for scaling print size? Is there any significant challenge to scaling the frame using existing components?

I'll assume we talk 500 in X, 500 in Y, and 1000 in Z. I'll also assume we're doing this on a TK-0 like design--but the options really are limitless. If you haven't seen TK-0, check out this: http://devel.lulzbot.com/TK-0/ We have the TK-0 in production at the factory right now, but aren't selling it yet. Just the first few have rolled off the assembly line so far (but the first one is the hardest, of course!).

The bot just needs to move smoothly in X, Y, & Z. Going up in Z is "easy". Just get a fat smooth rod and use taller extrusion. Worst case, the extrusion needs to be bigger than the 20mm we're using now (Misumi).

The X is currently on two 10mm rods. This is for a 300mm bot (on X) and is overbuilt, so we could probably stick with 10mm there. If we need bigger, it isn't too hard to change.

The Y is also on two 10mm rods. This starts to get a bit more complicated, as the Y moves on our bot. As you increase your build plate, it means Y has more weight to move. This includes a 500x500 aluminum plate, a heating element (currently a silicon pad, which is heavy), and a large sheet of borosilicate glass. It may need a larger motor. This isn't insurmountable.

2. If the frame can be scaled - what are the limiting factors determining max size of objects? Is it heating? Is it heat retention? Warping?

Warping is a *huge* factor, especially when you get to larger parts. It is the main limiting factor. Making a 500x500x1000 bot isn't hard. Getting a part that won't warp is. ABS, which most printers use, is very prone to warping. It may require being built in a heated chamber, but there are patents surrounding that. I don't know all the details of the patents. Also, doing a large heated build plate requires more power. Not that big of a deal. Just need to get a larger power supply and perhaps use multiple silicon pads, kapton heaters, or similar.

Other materials could be used instead of ABS. PLA is far less likely to warp than ABS. It also prints at a lower temperature. For something this large, you would probably want a heatbed for PLA as well.

Nylon could be used. It tends to warp off of glass plates, but we've printed it on Garolite happily ( http://devel.lulzbot.com/filament/nylon/ ). I don't know how much warping would be a problem with it at these large sizes.

I don't know what kinds of plastics they need for the car though. I've heard of ABS bumpers, but I have no idea whether nylon would be a suitable replacement or not.

Related to warping is delamination where the layers of the parts split. This is also way more likely as you print a large part.

Another big issue is time. Printing something that large may take a few *days*. It is very dependent on what resolution is needed. Also, the longer the print, the higher the chance of failure due to something happening during the print.

How fine do these prints have to be? They could easily be post-processed as well (e.g. in acetone vapor, sanding).

Do you have any reservations about collaborating with OSE?

I have no reservations whatsoever.

I imagine your business priorities may limit your ability to do further development. Given this constraint, how could we address this by bringing in more resources? Is the limiting resource design talent? Prototyping work?

The limiting factor is hands & minds to work on the job. We could sketch out a rough idea, point you at some potential suppliers for the more obscure parts, give you a preliminary BOM and you could take a run at it if you have the manpower. We already have a lot of the main parts available (electronics, motors, extruder). All the TK-0 parts are drawn in FreeCAD, so they can be easily modified. Do you have a pool of engineers sitting around looking for something to do? If so, lucky you! ;)

Let me know your thoughts. What is your cell number?

Also, I'm not our main engineer on our products--far from it. I do the paperwork. ;) I'll run this by our CTO as well to get his thoughts.

-Jeff

Conversations

Conversations

https://oshpark.com/ - they take KiCAD files.

git clone - https://code.alephobjects.com/diffusion/CIM/cimarron.git - KiCAD open source stepper driver

http://devel.lulzbot.com/research_projects/

https://code.alephobjects.com/diffusion/

https://code.alephobjects.com/diffusion/CIM/

code.alephobjects.org

debian administration manual

WebRTC

Collabora - cloud editable

Harris is President. Harris is interview guy.

Drupal - web cart

Enterprise Service Bus- Mule - FedEX, shipping cart, ERP, UPS, OpenProject, https://www.mulesoft.com/platform/soa/mule-esb-open-source-esb?utm_campaign=G_Brands_NA_Search_Mule_ESB_Features&utm_medium=cpc&utm_source=google&utm_term=mule%20integration

Cura 1- wrgtX

Cura 2 - cute KDE (qt) system. Much better.

Cura engine.

http://devel.alephobjects.com/ao/aodeb/

20:28

http://devel.lulzbot.com/filament/

https://devel.lulzbot.com/filament/Testing_Docs_Master/

Wed Jun 23, 2020

- https://www.crowdsupply.com/radiona/ulx3s

- Trellis Board -

- Existing chips + free software - https://twitter.com/fpga_dave?lang=en

- THey make 100M boards a day

- Xilinx - baords -

- Can do Linux on the FPGA

- You can do RISCV - booting Linux on FPGA

- FPGA that could boot Linux

- Clear Mylar to do masks - laser cutting it - BGA - Ball Grid Arrays - [2]

- Fine holes with cheap laser - to get BGA manufacturing possibility.

- https://make4covid.co/team/

- Motion control on Farmbot -

- SATnog - [3]

- Libre Space Foundation - nice!

- https://libre.space/2019/05/25/oscw19-call-for-participation-now-open/

- https://libre.space/2019/05/25/oscw19-call-for-participation-now-open/

- Shinobi + tensorflow

- Start with a clone of archives -

- Git clone - first thing devs do. Suggestion: get our stuff available via Git Clone for each project. Maybe that's what we do with all of our machines. But that means taking the time to do it so there is distilled material.