Spray Transfer: Difference between revisions

Jump to navigation

Jump to search

No edit summary |

No edit summary |

||

| Line 10: | Line 10: | ||

==Video== | ==Video== | ||

<html><iframe width="420" height="315" src="https://www.youtube.com/embed//NXh5jB5a4Zw" frameborder="0" allowfullscreen></iframe></html> | <html><iframe width="420" height="315" src="https://www.youtube.com/embed//NXh5jB5a4Zw" frameborder="0" allowfullscreen></iframe></html> | ||

<br/> | |||

<html><iframe width="420" height="315" src="//www.youtube.com/embed/PI3pZxoPRvA" frameborder="0" allowfullscreen></iframe></html> | |||

==Takeaway== | ==Takeaway== | ||

Welding mode on high power and low wire feed rate. | Welding mode on high power and low wire feed rate. | ||

Jody actually recommends higher feed rate and a 90/10 argon/CO2 mix | |||

Revision as of 15:06, 21 April 2014

Description

From MIG Welding Handbook:

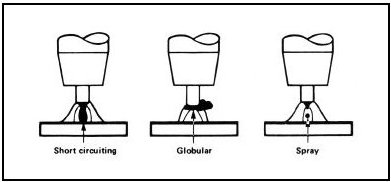

- The basic mig process includes three distinctive process techniques: short circuiting metal transfer, globular transfer, and spray arc. These techniques describe the manner in which metal is transferred from the wire to the weld pool. In short circuiting metal transfer, also known as ”Short Arc”, ”Dip Transfer”, and ”Microwire”, metal transfer occurs when an electrical short circuit is established. This occurs as the molten metal at the end of the wire touches the molten weld pool. In spray arc welding, small molten drops of metal are detached from the tip of the wire and projected by electromagnetic forces towards the weld pool

Video

Takeaway

Welding mode on high power and low wire feed rate.

Jody actually recommends higher feed rate and a 90/10 argon/CO2 mix