Spray Transfer

Description

From MIG Welding Handbook:

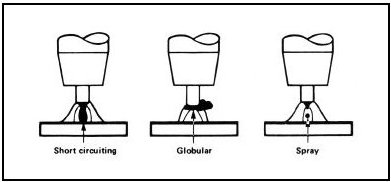

- The basic mig process includes three distinctive process techniques: short circuiting metal transfer, globular transfer, and spray arc. These techniques describe the manner in which metal is transferred from the wire to the weld pool. In short circuiting metal transfer, also known as ”Short Arc”, ”Dip Transfer”, and ”Microwire”, metal transfer occurs when an electrical short circuit is established. This occurs as the molten metal at the end of the wire touches the molten weld pool. In spray arc welding, small molten drops of metal are detached from the tip of the wire and projected by electromagnetic forces towards the weld pool

Video

Takeaway

Welding mode on high power and low wire feed rate.

Jody actually recommends higher feed rate and a 90/10 argon/CO2 mix

From weldingweb

Re: Spray transfer questions Quote Originally Posted by vpd66 View Post I'm using argon and CO2 with a Smith 2 gas mixer. I can't get my Millermatic 250 to weld in spray transfer with 75/25.can just barely get into spray transfer with 80/20 gas, .035 wire, and around 30 volts. With 95/5 it will go into spray at 28 volts. Just a tick under 28 volts and nope it starts sputtering. Yeah, C25 is not really the gas mix to use for spray transfer. Just too much CO2 percentage to realistically get into spray mode. Anything more than about 15% CO2 in the mix and spray transfer usually isn't happening (well, consistently, or reliably).

(IIRC, someone, somewhere, really-really-REALLY-really cranked up the voltage and supposedly got spray mode going with C25. IIRC, the voltage was somewhere closer to 40V than to 30V. ) )

C10, C5, C2, or 98-2 Ar-O2 for spray usually.

0.030 wire, spray at about 25V and a bit over 500 ipm WFS, around 180 amps or so.

0.035 wire, spray at about 26V and just a little under 500 ipm WFS, around 200 amps or so.

0.045 wire, spray at about 27V and 350 ipm WFS, around 300 amps.

That's with 98-2 Ar-O2. Nudge the voltage up 1-2 volts if using Ar-CO2, depending on just how much CO2 % is in your gas mix (again, don't really go over 15% CO2 for spray mode.)

Usual GMAW porosity sources:

- Workpiece contamination (clean the metal!!! Front and back and bevel, and no, using a wire wheel is not actually cleaning to bright shiny metal.) - Bad gas (happens sometimes, sometimes a fitting or hose is the issue and not the gas itself) - Shielding gas coverage (watch out for drafts, turbulence, spatter in the nozzle, etc) - Contaminated wire - Too high of a voltage setting - Excess stick-out

Spray mode is hot, fast, hiss, and a fluid puddle.

If you suddenly get sputtering (and spatter balls popping around), you might have dropped into globular transfer. Or hit a bunch of non-metal (anything other than clean shiny metal) and that spattered.

Other than that, pretty much what Dan said.