Stock Bonding Plate: Difference between revisions

Jump to navigation

Jump to search

No edit summary |

|||

| (7 intermediate revisions by the same user not shown) | |||

| Line 1: | Line 1: | ||

=FreeCAD 2016= | |||

[[File:stockbondingplate.fcstd]] | |||

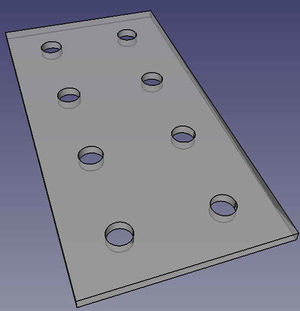

[[Image:stockbondingplate.jpg|thumb|Stock bonding plate in FreeCAD, 1/2" mild steel.]] | |||

=LifeTrac 6 - August 2013= | |||

*Holes increased by 1/16" to 1-1/8" in diameter for easier bolt fit | |||

[[File:lt6stockplate.dxf]] | |||

=6 in 60 - July 2013= | |||

Units in Inches: | |||

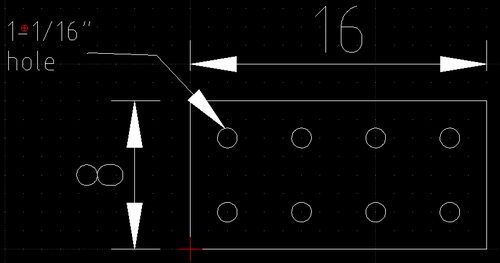

[[Image:bondplate.png|500px]] | [[Image:bondplate.png|500px]] | ||

[[File:stockbondplate.dxf]] | [[File:stockbondplate.dxf]] | ||

=Real Life Picture= | |||

Needed... | |||

=Alternatives= | |||

To minimize hot cutting, one can cut out a longer length of material and subsequently cut it with an ironworker machine to save on cutting time if endstops are used for measuring material length. This is a file of 4 stock bonding plates cut together, 1-1/8" holes, credits [[Lucas Log]]. | |||

[[File:stockbondlong.dxf]] | |||

Latest revision as of 02:52, 17 May 2016

FreeCAD 2016

LifeTrac 6 - August 2013

- Holes increased by 1/16" to 1-1/8" in diameter for easier bolt fit

6 in 60 - July 2013

Units in Inches:

Real Life Picture

Needed...

Alternatives

To minimize hot cutting, one can cut out a longer length of material and subsequently cut it with an ironworker machine to save on cutting time if endstops are used for measuring material length. This is a file of 4 stock bonding plates cut together, 1-1/8" holes, credits Lucas Log.