Talk:CEB Press v16.09/SCAD Files: Difference between revisions

Jump to navigation

Jump to search

(Created page with "=TO DO= *do a full assembly *begin making design parametric - start a new "SCAD Files - Parametric" page **Frame length and mounting hole dimensions based on cylinder **set...") |

|||

| (9 intermediate revisions by the same user not shown) | |||

| Line 2: | Line 2: | ||

*do a full assembly | *do a full assembly | ||

**notate which adjoining part corresponds with each cutout | |||

*begin making design parametric - start a new "SCAD Files - Parametric" page | *begin making design parametric - start a new "SCAD Files - Parametric" page | ||

| Line 11: | Line 12: | ||

*Layout for CNC | *Layout for CNC | ||

=Design Suggestions= | |||

===Frame=== | |||

suggest adding new diagnal support part that welds between F5 and F4 to guarantee 90 degree weld and prevent bending under loads --[[User:Dorkmo|Dorkmo]] ([[User talk:Dorkmo|talk]]) 03:50, 31 May 2017 (CEST) | |||

=Design Method= | |||

==Module Insert== | |||

a whole cut to allow for a matching tab to be placed within it and welded | |||

due to the varriance in styles this needs to be a flexiible module | |||

variables will be the height and width of the tab to be inserted, the gap to be left between the tab and the insert's wall, and 2 measurements for each corner cut, and the depth of the corner cut from the rest of the cut. | |||

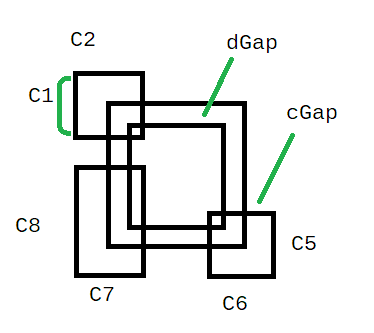

[[image:ceb_scadinsertdiagram.png]] | |||

<nowiki> | |||

insert(2,1,0.5,0.125,0.125,0.125,0.125,0.25,0.25,0.125,0.125,0.25,0.25,1); | |||

module insert(X,Y,Z,dGap,cGap,c1,c2,c3,c4,c5,c6,c7,c8,center){ | |||

translate([-dGap-(center*(X/2)),-dGap-(center*(Y/2)),0]){ | |||

//main cut | |||

cube([X+(dGap*2),Y+(dGap*2),Z]); | |||

//corner c1c2 | |||

translate([-cGap,(Y+(dGap*2))-c1+cGap,0]) | |||

{ | |||

cube([c2,c1,Z]);} | |||

//corner c3c4 | |||

translate([(X+(dGap*2))-c3+cGap,(Y+(dGap*2))-c4+cGap,0]){ | |||

cube([c3,c4,Z]); | |||

} | |||

//corner c5c6 | |||

translate([(X+(dGap*2))-c6+cGap,-cGap,0]) | |||

{ | |||

cube([c6,c5,Z]); | |||

} | |||

//corner c7c8 | |||

translate([-cGap,-cGap,0]){ | |||

cube([c7,c8,Z]); | |||

} | |||

} //end center translate | |||

} | |||

</nowiki> | |||

Latest revision as of 02:17, 2 June 2017

TO DO

- do a full assembly

- notate which adjoining part corresponds with each cutout

- begin making design parametric - start a new "SCAD Files - Parametric" page

- Frame length and mounting hole dimensions based on cylinder

- set size of brick, drawer parts change to fit

- fix bugs in design

- standardize sizes where possible

- Layout for CNC

Design Suggestions

Frame

suggest adding new diagnal support part that welds between F5 and F4 to guarantee 90 degree weld and prevent bending under loads --Dorkmo (talk) 03:50, 31 May 2017 (CEST)

Design Method

Module Insert

a whole cut to allow for a matching tab to be placed within it and welded

due to the varriance in styles this needs to be a flexiible module

variables will be the height and width of the tab to be inserted, the gap to be left between the tab and the insert's wall, and 2 measurements for each corner cut, and the depth of the corner cut from the rest of the cut.

insert(2,1,0.5,0.125,0.125,0.125,0.125,0.25,0.25,0.125,0.125,0.25,0.25,1);

module insert(X,Y,Z,dGap,cGap,c1,c2,c3,c4,c5,c6,c7,c8,center){

translate([-dGap-(center*(X/2)),-dGap-(center*(Y/2)),0]){

//main cut

cube([X+(dGap*2),Y+(dGap*2),Z]);

//corner c1c2

translate([-cGap,(Y+(dGap*2))-c1+cGap,0])

{

cube([c2,c1,Z]);}

//corner c3c4

translate([(X+(dGap*2))-c3+cGap,(Y+(dGap*2))-c4+cGap,0]){

cube([c3,c4,Z]);

}

//corner c5c6

translate([(X+(dGap*2))-c6+cGap,-cGap,0])

{

cube([c6,c5,Z]);

}

//corner c7c8

translate([-cGap,-cGap,0]){

cube([c7,c8,Z]);

}

} //end center translate

}