Turbine Fabrication: Difference between revisions

No edit summary |

No edit summary |

||

| Line 18: | Line 18: | ||

[[Image:Turbine_fab4.jpg]] | [[Image:Turbine_fab4.jpg]] | ||

Start with | Begin work on the other shaft end. Start with ball bearing. Sourcing: ____ . Cost: | ||

[[Image:Turbine_fab5.jpg]] | [[Image:Turbine_fab5.jpg]] | ||

Revision as of 17:17, 19 March 2008

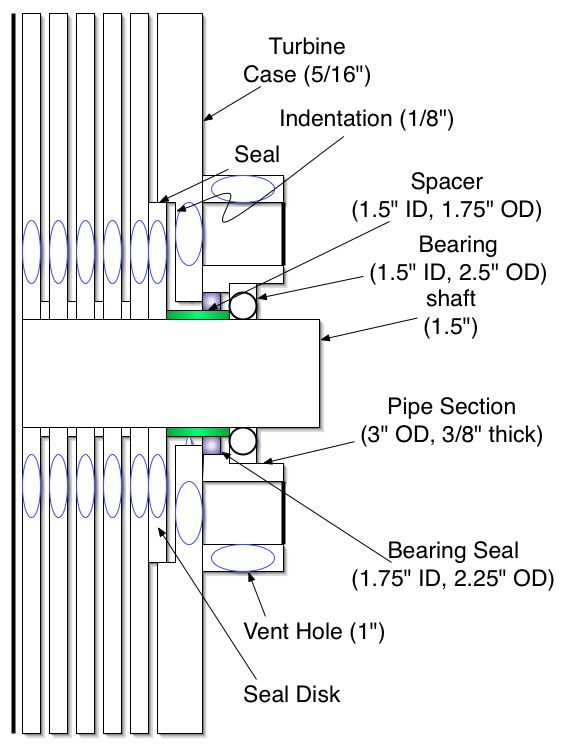

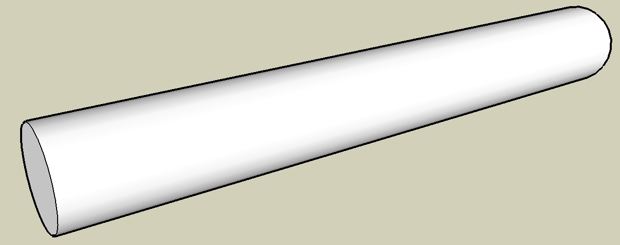

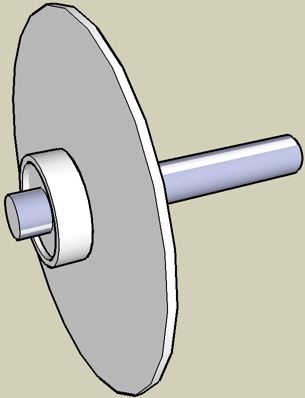

The turbine fabrication procedure starts with a 1.5” shaft. Sourcing: part # 8920K312 at McMaster Carr. Cost: $15

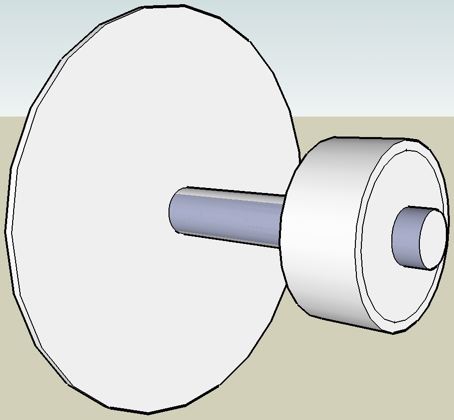

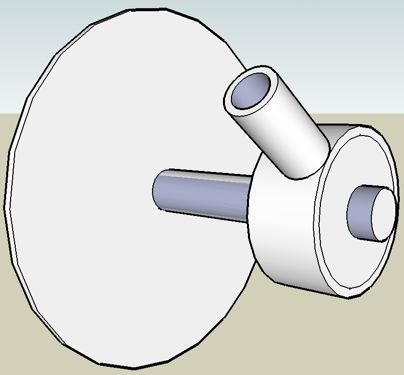

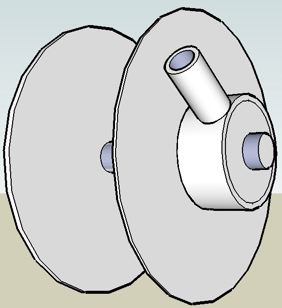

The turbine fabrication is almost wholly symmetrical for the two sides, except for the provisions for exhaust. The side with the exhaust has two features that the other side does not have: a main working gas seal and the exhaust manifold. Look at the picture of the exhaust end:

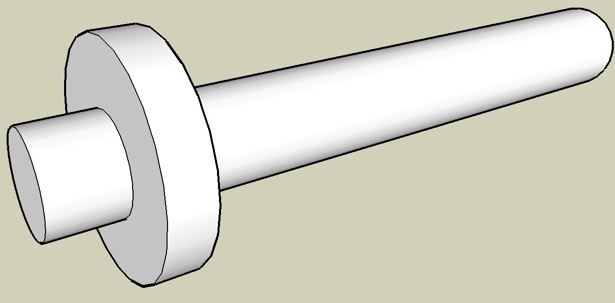

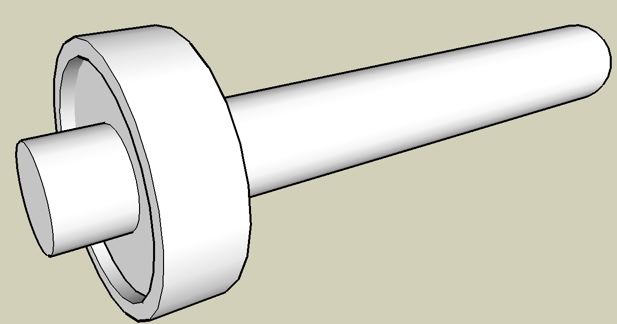

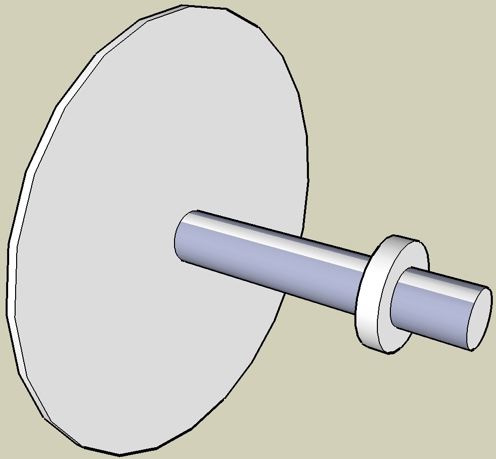

Both sides have bearings, spacers, seals, and clamping collar. Find a bearing to fit the shaft and slide it on the shaft. Sourcing: part 60355K84 at [1] for $38 or [2] for $9, or Ebay for $20 each.

Also, find a spacer, with 1.5 inch ID and 1/8” wall. It is 1/4” long + width of seal (see seal design drawing). Sourcing: ______ Cost:

Also, find a seal to match the spacer. 1.75” ID and 3” OD.

Find end pipe section to house the bearing, seal, and spacer. Sourcing: ____ . Cost:

Find 5/16” plate steel for end side of turbine. Sourcing: ____ . Cost:

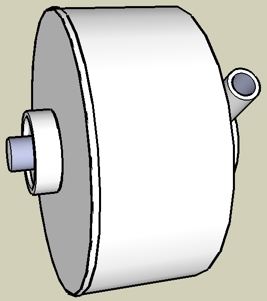

Begin work on the other shaft end. Start with ball bearing. Sourcing: ____ . Cost:

Start with a 1.5” shaft. Sourcing: ____ . Cost:

Start with a 1.5” shaft. Sourcing: ____ . Cost:

Start with a 1.5” shaft. Sourcing: ____ . Cost:

Start with a 1.5” shaft. Sourcing: ____ . Cost:

Start with a 1.5” shaft. Sourcing: ____ . Cost: File:Turbine fab10.jpg