Precious Plastic Shredder: Difference between revisions

No edit summary |

(→Screen) |

||

| Line 9: | Line 9: | ||

Shredder screen width based on angle - uses PDF of fabrication drawings imported into FreeCAD for tracing over | Shredder screen width based on angle - uses PDF of fabrication drawings imported into FreeCAD for tracing over | ||

[[File:screen.png]] | [[File:screen.png|400px]] | ||

Source: [[File:screen.fcstd]] | Source: [[File:screen.fcstd]] | ||

Revision as of 22:49, 11 August 2018

Source

- https://preciousplastic.com/en/videos/build/shredder.html

- Imperial version of knives for shredder - for 1" hex shaft - https://davehakkens.nl/community/forums/topic/shredder-modifications/

- Imperial steel overall - https://davehakkens.nl/community/forums/topic/shredder-converted-to-imperial-system-inches/

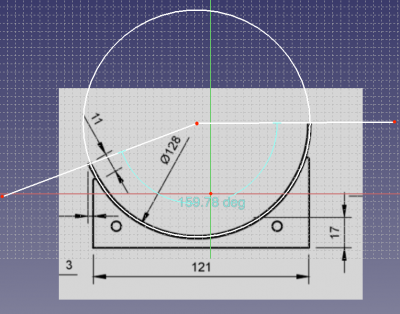

Screen

Shredder screen width based on angle - uses PDF of fabrication drawings imported into FreeCAD for tracing over

Source: File:Screen.fcstd

OSE Mod

See working team meeting -

The Precious Plastic shredder is great. By using 1" hex shaft and 1" hex bearings, we avoid machining the shaft ends. Using 3D printing, a hex coupler is obtained readily, printed at 100% infill.

The advantage of using hex for the coupler is not needing keyways or set screws, though these can be used for additional holding force.

If PLA is 7250 PSI, that is 1/5 of mild steel. Thus, a plastic coupler can readily do 1000s of lbs of shaft holding force. FOr example, on a 1" shaft, one can likely attain 15000 in lb of hold using a coupler with 3/4" walls. It is useful to use a coupler with a metal sleeve, using 2" schedule 40 pipe, with the coupler press fit inside of the sleeve for a metal-plastic composite coupler. The plastic walls in this case would be around .5".

Builds