Turbine Fabrication: Difference between revisions

No edit summary |

No edit summary |

||

| (13 intermediate revisions by 2 users not shown) | |||

| Line 1: | Line 1: | ||

{{Category=Solar Turbine}} | |||

=General Fabrication Procedure= | |||

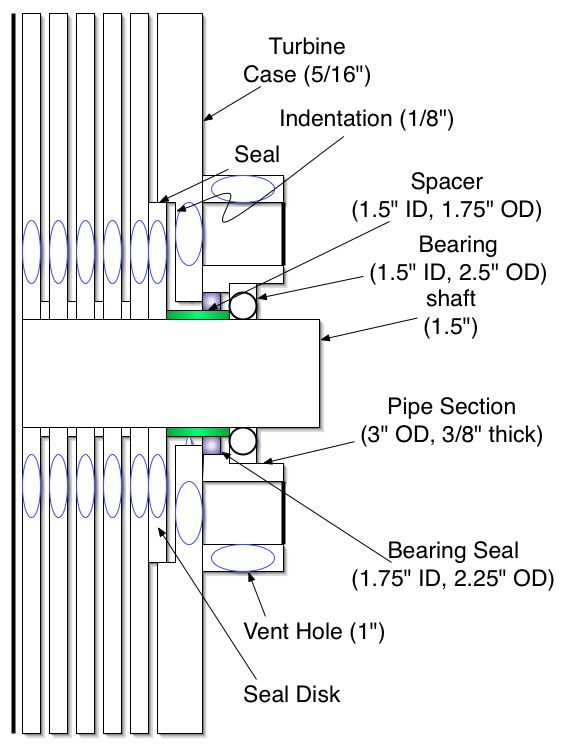

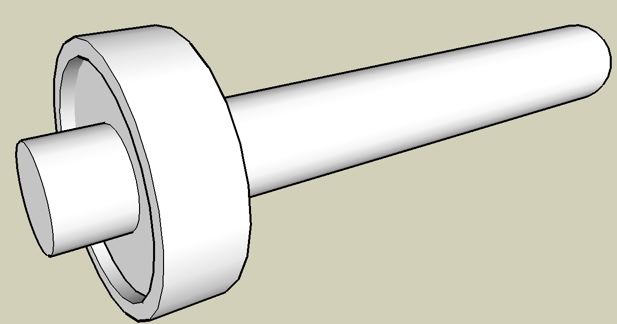

The turbine fabrication procedure starts with a 1.5” shaft. Sourcing: part # 8920K312 at [http://www.mcmaster.com/ McMaster Carr]. Cost: $15 | The turbine fabrication procedure starts with a 1.5” shaft. Sourcing: part # 8920K312 at [http://www.mcmaster.com/ McMaster Carr]. Cost: $15 | ||

[[Image:Turbine_shaft.jpg]] | [[Image:Turbine_shaft.jpg]] | ||

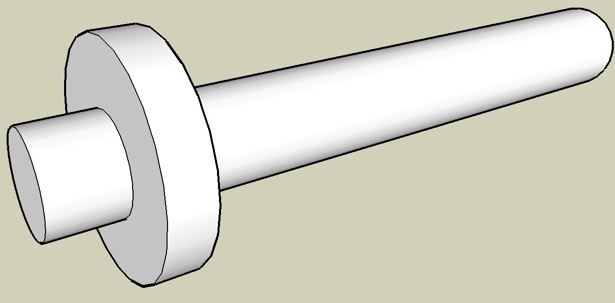

[[Image:Turbine_fab1.jpg]] | [[Image:Turbine_fab1.jpg]] | ||

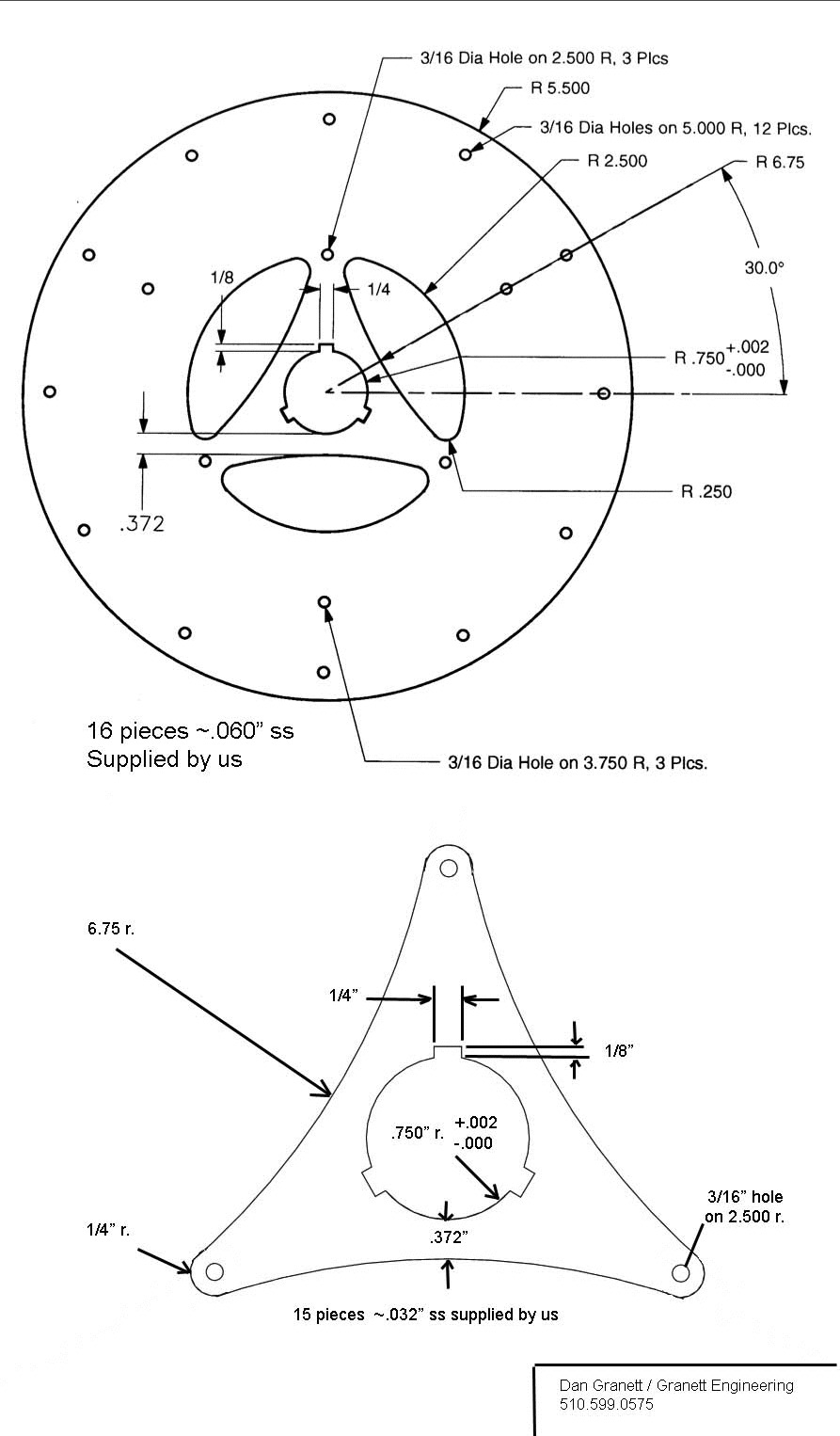

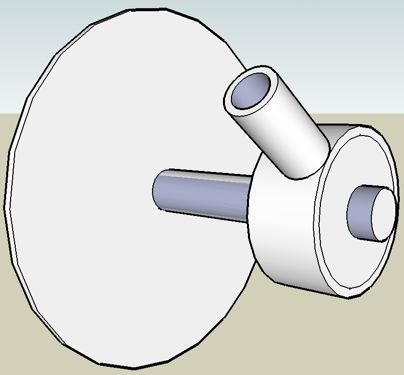

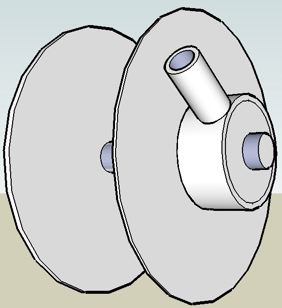

The turbine fabrication is almost wholly symmetrical for the two sides, except for the provisions for exhaust. The side with the exhaust has two features that the other side does not have: a main working gas seal and the exhaust manifold. Look at the picture of the exhaust end: | |||

Find a bearing to fit the shaft. Sourcing: | [[Image:turbine_dimensions.jpg]] | ||

Both sides have bearings, spacers, seals, and clamping collar. Find a bearing to fit the shaft and slide it on the shaft. Sourcing: part 60355K84 at [http://www.mcmaster.com/] for $38 or [http://surpluscenter.com/item.asp?UID=2008021321021066&item=1-208-24-B&catname=] for $9, or [http://cgi.ebay.com/Lot-Of-2-Sealmaster-ER-24-1-1-2-Ball-Bearings-NIB_W0QQitemZ270167202025QQihZ017QQcategoryZ25284QQtcZphotoQQcmdZViewItemQQ_trksidZp1742.m153.l1262#ebayphotohosting Ebay] for $20 each. | |||

Also, find a spacer, with 1.5 inch ID and 1/8” wall. It is 1/4” long + width of seal (see seal design drawing). Sourcing: ______ Cost: | Also, find a spacer, with 1.5 inch ID and 1/8” wall. It is 1/4” long + width of seal (see seal design drawing). Sourcing: ______ Cost: | ||

Also, find a seal to match the spacer. 1.75” ID and 3” OD. | Also, find a seal to match the spacer. 1.75” ID and 3” OD. | ||

| Line 15: | Line 21: | ||

[[Image:Turbine_fab4.jpg]] | [[Image:Turbine_fab4.jpg]] | ||

Start with | Begin work on the other shaft end. Start with ball bearing. Sourcing: ____ . Cost: | ||

[[Image:Turbine_fab5.jpg]] | [[Image:Turbine_fab5.jpg]] | ||

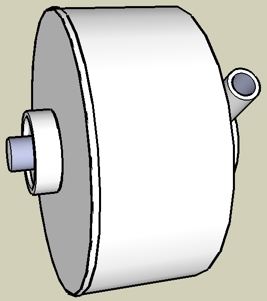

Begin work on the exhaust compartment. Use a larger pipe section to house the exhaust holes. Sourcing: ____ . Cost: | |||

[[Image:Turbine_fab6.jpg]] | [[Image:Turbine_fab6.jpg]] | ||

Cut out exhaust port and weld on an exhaust pipe. Sourcing: ____ . Cost: | |||

[[Image:Turbine_fab7.jpg]] | [[Image:Turbine_fab7.jpg]] | ||

Lathe out another end plate. Sourcing: ____ . Cost: | |||

[[Image:Turbine_fab8.jpg]] | [[Image:Turbine_fab8.jpg]] | ||

Install middle pipe section. Drill small holes into end plates to bind sections together. Use gasket sealing compound for vapor-tightness. Sourcing: ____ . Cost: | |||

[[Image:Turbine_fab9.jpg]] | [[Image:Turbine_fab9.jpg]] | ||

The disks may now be inserted onto the shaft. Locking collars and spacers must be accommodated, as well as seals. | |||

[[Image: | |||

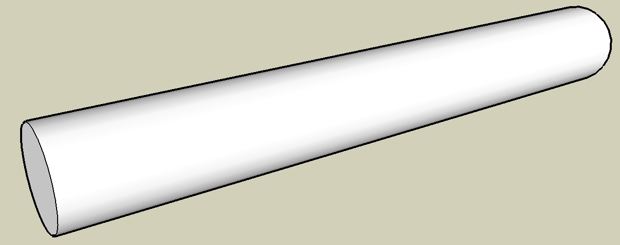

=Disks= | |||

Picture of disks, cut out by laser cutter: | |||

[[Image:disks_quote.jpg]] | |||

=Tolerances= | |||

[[Boundary Layer Turbine]] | |||

=Review and Comments= | |||

Submit your comments here. | |||

Latest revision as of 15:48, 15 February 2011

Main > Energy > Solar Power > Solar Turbine

General Fabrication Procedure

The turbine fabrication procedure starts with a 1.5” shaft. Sourcing: part # 8920K312 at McMaster Carr. Cost: $15

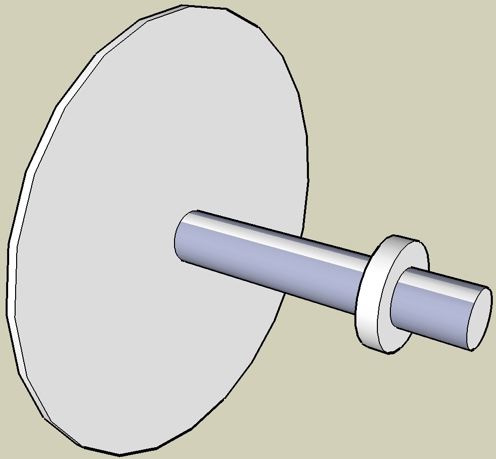

The turbine fabrication is almost wholly symmetrical for the two sides, except for the provisions for exhaust. The side with the exhaust has two features that the other side does not have: a main working gas seal and the exhaust manifold. Look at the picture of the exhaust end:

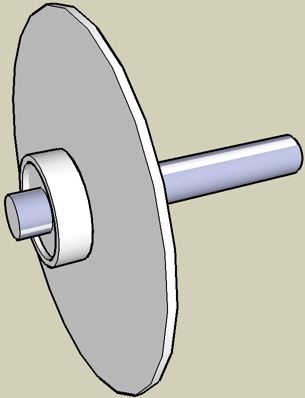

Both sides have bearings, spacers, seals, and clamping collar. Find a bearing to fit the shaft and slide it on the shaft. Sourcing: part 60355K84 at [1] for $38 or [2] for $9, or Ebay for $20 each.

Also, find a spacer, with 1.5 inch ID and 1/8” wall. It is 1/4” long + width of seal (see seal design drawing). Sourcing: ______ Cost:

Also, find a seal to match the spacer. 1.75” ID and 3” OD.

Find end pipe section to house the bearing, seal, and spacer. Sourcing: ____ . Cost:

Find 5/16” plate steel for end side of turbine. Sourcing: ____ . Cost:

Begin work on the other shaft end. Start with ball bearing. Sourcing: ____ . Cost:

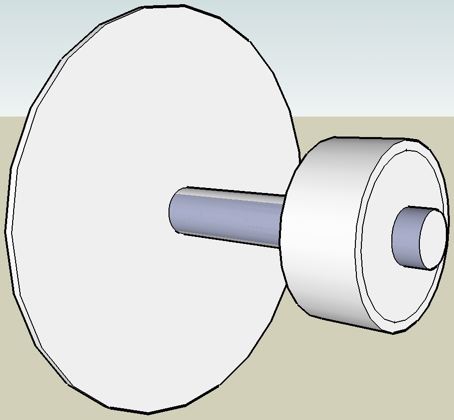

Begin work on the exhaust compartment. Use a larger pipe section to house the exhaust holes. Sourcing: ____ . Cost:

Begin work on the exhaust compartment. Use a larger pipe section to house the exhaust holes. Sourcing: ____ . Cost:

Cut out exhaust port and weld on an exhaust pipe. Sourcing: ____ . Cost:

Lathe out another end plate. Sourcing: ____ . Cost:

Install middle pipe section. Drill small holes into end plates to bind sections together. Use gasket sealing compound for vapor-tightness. Sourcing: ____ . Cost:

The disks may now be inserted onto the shaft. Locking collars and spacers must be accommodated, as well as seals.

Disks

Picture of disks, cut out by laser cutter:

Tolerances

Review and Comments

Submit your comments here.