Don Log: Difference between revisions

Djacobsmeyer (talk | contribs) No edit summary |

Djacobsmeyer (talk | contribs) No edit summary |

||

| Line 1: | Line 1: | ||

= Mon Jan 27, 2020 = | = Mon Jan 27, 2020 = | ||

| Line 26: | Line 13: | ||

- The left/right & upper/lower coordinate settings are very relevant to how the plotter arranges itself on the print bed. | - The left/right & upper/lower coordinate settings are very relevant to how the plotter arranges itself on the print bed. | ||

- Speed settings could be increased as high as 150 mm/s. NOTE: these speeds over-ride the speed settings which can manually be set on the marlin controller. | - Speed settings could be increased as high as 150 mm/s. NOTE: these speeds over-ride the speed settings which can manually be set on the marlin controller. | ||

= Sun Jan 26, 2020 = | |||

== Startup Issues == | |||

After much troubleshooting Discovered that the Filament diameter size in the slicer files was set too low, which caused the extrusion feeder to feed to much material. We incorrectly adjusted the M92 variable to E425 thinking that would adjust the steps/mm, yet that made the problem worse. After we discovered this, setting the diameter to the proper 2.85mm size and the M92 to E100 corrected the problem. | |||

Known good gcode test file [[File:hollow10.gcode.zip]] | |||

Separate from this issue, I've discovered that there may be a subtle misalignment in the filament pipeline which causes a problem in the extruder assembly to clog or jam. | |||

== Process Improvement Research == | |||

There is an open source kanban board tool (https://wekan.github.io/) which already has a dockerfile for rapid easy deployment for local use or distributed use. This can be run on a RsPi as well. | |||

Revision as of 15:29, 28 January 2020

Mon Jan 27, 2020

Plotter

Discovered that the Inkscape plugin was already installed on OSE Linux.

Discussed with Marcin that the plotter attachment requires removing the extrusion assembly, yet using the bed level sensor still. That seemed unnecessary. We talked about simply modifying the existing cooling+sensor assembly to include an additional slot to insert a ~.75" plotter attachment directly to the extrusion assembly, preventing the need to change out print heads. File:ExtrCoolSensPlt.fcstd

Created standard plotter attachment with pen holder clip. Discovered my print settings had spiral fill enabled which prevented proper plotter attachment walls and overhang/ceiling to be printed.

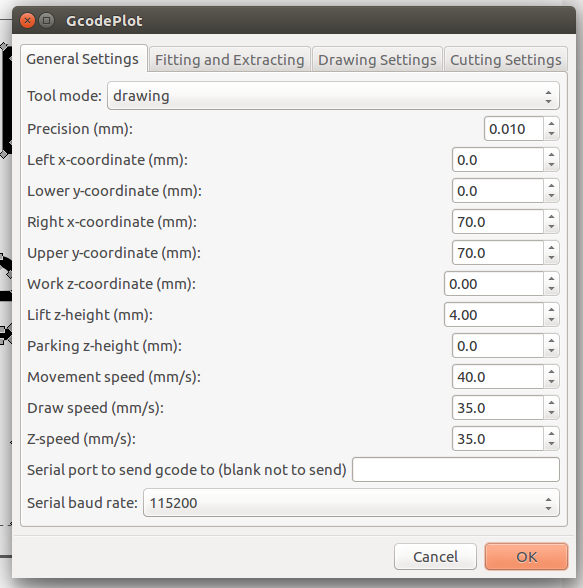

Inkscape has many setting to review when exporting (save as) to gcode.  The notable ones I reviewed are as follows:

- Precision setting should be set to 0.010 to correspond to the 10 microns of accuracy that the D3D printer is designed to achieve.

- The left/right & upper/lower coordinate settings are very relevant to how the plotter arranges itself on the print bed.

- Speed settings could be increased as high as 150 mm/s. NOTE: these speeds over-ride the speed settings which can manually be set on the marlin controller.

The notable ones I reviewed are as follows:

- Precision setting should be set to 0.010 to correspond to the 10 microns of accuracy that the D3D printer is designed to achieve.

- The left/right & upper/lower coordinate settings are very relevant to how the plotter arranges itself on the print bed.

- Speed settings could be increased as high as 150 mm/s. NOTE: these speeds over-ride the speed settings which can manually be set on the marlin controller.

Sun Jan 26, 2020

Startup Issues

After much troubleshooting Discovered that the Filament diameter size in the slicer files was set too low, which caused the extrusion feeder to feed to much material. We incorrectly adjusted the M92 variable to E425 thinking that would adjust the steps/mm, yet that made the problem worse. After we discovered this, setting the diameter to the proper 2.85mm size and the M92 to E100 corrected the problem.

Known good gcode test file File:Hollow10.gcode.zip

Separate from this issue, I've discovered that there may be a subtle misalignment in the filament pipeline which causes a problem in the extruder assembly to clog or jam.

Process Improvement Research

There is an open source kanban board tool (https://wekan.github.io/) which already has a dockerfile for rapid easy deployment for local use or distributed use. This can be run on a RsPi as well.