Parametric Sprocket: Difference between revisions

Jump to navigation

Jump to search

No edit summary |

|||

| (12 intermediate revisions by the same user not shown) | |||

| Line 1: | Line 1: | ||

*http://www.thingiverse.com/thing: | *Source: '''http://www.thingiverse.com/thing:7918''' | ||

*The | =How to Design a Sprocket for Bulldozer Drive= | ||

*The sprocket generator in OpenSCAD creates a proportionally correct sprocket. | |||

*How do we know how to scale it to match our specific case? | |||

*We first design the track. We settled on pin spacing of 3", and XXH 1.5" pipe (see [[Pipe Chart]]) for the roller, with 1" pins. Thus: roller = 1.9" OD (1.5" XXH pipe), pitch = 3" (based on geometry of pins: | |||

[[File:trackpad.png|200px]] | |||

*'''Ratio of 3/1.9=1.58. Ratio of pitch to the roller is constant. | |||

*Then we generate the sprocket using 5 parameters | |||

:*1 - Number of teeth | |||

:*2 - Roller (5 units) | |||

:*3 - Pitch - 1.58x the roller size as determined by our track geometry (looks sensible, and 3" pitch was selected as a convenient distance, and 1.9" OD roller was selected as a readily-available stock material | |||

:*4 - Thickness - that is the thickness of the plate material | |||

:*5 - Tolerance - play in the distance between rollers (pitch)? | |||

*To generate a correct sprocket, we can scale the resulting design in CAD - by superposing the track piece over the sprocket to make sure the track pieces fit in the valley-to-valley distance in the sprocket (which corresponds to the distance between rollers, or pitch) | |||

:*See the [[File:Sprocketgeo.dxf]] for how the track pieces fit into the sprocket (example shows a larger sprocket than an 8 tooth sprocket) | |||

=Bulldozer 2015 Usage= | |||

{{Hint|The bulldozer from 2015 used an 8 tooth sprocket, generated with sprocket(8,5,7.5,2,0.2); in the last line of the Editor}} | |||

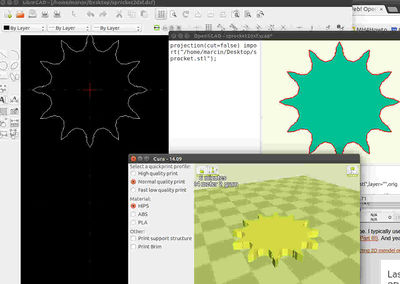

=Exporting DXFs from 3D Objects in OpenSCAD= | =Exporting DXFs from 3D Objects in OpenSCAD= | ||

| Line 11: | Line 28: | ||

:*Note: original srocket was generated using [[Parametric Sprocket Generator]] using sprocket(12,5,7.5,8,0.2); | :*Note: original srocket was generated using [[Parametric Sprocket Generator]] using sprocket(12,5,7.5,8,0.2); | ||

=Links= | |||

*Sprocket geometry for a correct sprocket pitch and roller diameter - example - [[File:sprocketgeo.dxf]] | |||

:*Uses [[Sprocket Generator]] | |||

[[Image:dxfexportex.jpg|400px]] | [[Image:dxfexportex.jpg|400px]] | ||

Latest revision as of 16:00, 25 December 2020

How to Design a Sprocket for Bulldozer Drive

- The sprocket generator in OpenSCAD creates a proportionally correct sprocket.

- How do we know how to scale it to match our specific case?

- We first design the track. We settled on pin spacing of 3", and XXH 1.5" pipe (see Pipe Chart) for the roller, with 1" pins. Thus: roller = 1.9" OD (1.5" XXH pipe), pitch = 3" (based on geometry of pins:

- Ratio of 3/1.9=1.58. Ratio of pitch to the roller is constant.

- Then we generate the sprocket using 5 parameters

- 1 - Number of teeth

- 2 - Roller (5 units)

- 3 - Pitch - 1.58x the roller size as determined by our track geometry (looks sensible, and 3" pitch was selected as a convenient distance, and 1.9" OD roller was selected as a readily-available stock material

- 4 - Thickness - that is the thickness of the plate material

- 5 - Tolerance - play in the distance between rollers (pitch)?

- To generate a correct sprocket, we can scale the resulting design in CAD - by superposing the track piece over the sprocket to make sure the track pieces fit in the valley-to-valley distance in the sprocket (which corresponds to the distance between rollers, or pitch)

- See the File:Sprocketgeo.dxf for how the track pieces fit into the sprocket (example shows a larger sprocket than an 8 tooth sprocket)

Bulldozer 2015 Usage

![]() Hint: The bulldozer from 2015 used an 8 tooth sprocket, generated with sprocket(8,5,7.5,2,0.2); in the last line of the Editor

Hint: The bulldozer from 2015 used an 8 tooth sprocket, generated with sprocket(8,5,7.5,2,0.2); in the last line of the Editor

Exporting DXFs from 3D Objects in OpenSCAD

- Exporting DXFs - [1] - essentially - load and flatten, then export DXF

- Note: stock Export DXF does not work for 3D files - they need to be projected first.

- To project - projection(cut=false) import("sprocket.stl"); STL file must exist in same directory

- Sample file for exercise in OpenSCAD - the sprocket STL and the .scad file that loads the STL and does a 2D projection. Note that the directory must be correct. File:Sprocketexample.zip

- Note: original srocket was generated using Parametric Sprocket Generator using sprocket(12,5,7.5,8,0.2);

Links

- Sprocket geometry for a correct sprocket pitch and roller diameter - example - File:Sprocketgeo.dxf

- Uses Sprocket Generator