Power Cube v16.09: Difference between revisions

(→BOM) |

(→Links) |

||

| (20 intermediate revisions by the same user not shown) | |||

| Line 1: | Line 1: | ||

=3D Image= | |||

3D Manipulable file in Sketchup: | |||

<html><iframe src="https://3dwarehouse.sketchup.com/embed.html?mid=ef39a7d5-911b-4618-a48a-1f5d09757489&width=580&height=326" frameborder="0" scrolling="no" marginheight="0" marginwidth="0" width="580" height="326" allowfullscreen></iframe></html> | |||

[https://3dwarehouse.sketchup.com/model.html?id=ef39a7d5-911b-4618-a48a-1f5d09757489 Download file in Sketchup] | |||

*Note: this needs to be converted from its proprietary Sketchup format into FreeCAD for editing, and WebGL for embedding. | |||

=Presentation= | |||

<html><iframe src="https://docs.google.com/presentation/d/1UhyjmUfqmBjtmrkWjp7wnR8B0_fDiOLnDJHXxFClVIE/embed?start=false&loop=false&delayms=3000#2" frameborder="0" width="960" height="569" allowfullscreen="true" mozallowfullscreen="true" webkitallowfullscreen="true"></iframe></html> | |||

[https://docs.google.com/presentation/d/1UhyjmUfqmBjtmrkWjp7wnR8B0_fDiOLnDJHXxFClVIE/edit edit] | |||

=Muffler= | |||

<html><iframe src="https://www.facebook.com/plugins/post.php?href=https%3A%2F%2Fwww.facebook.com%2Fmarcin.jakubowski.378%2Fposts%2F10208458707882399&width=500" width="500" height="683" style="border:none;overflow:hidden" scrolling="no" frameborder="0" allowTransparency="true"></iframe></html> | |||

=Design Review= | |||

Note: v16.09 denotes the month/year of active development on the Power Cube, according to OSE naming standards. | |||

<html><iframe width="560" height="315" src="https://www.youtube.com/embed/7xNk1_I_KQU" frameborder="0" allowfullscreen></iframe></html> | |||

=Design= | =Design= | ||

<html><iframe src="https://3dwarehouse.sketchup.com/embed.html?mid=ef39a7d5-911b-4618-a48a-1f5d09757489&width=580&height=326" frameborder="0" scrolling="no" marginheight="0" marginwidth="0" width="580" height="326" allowfullscreen></iframe></html> | <html><iframe src="https://3dwarehouse.sketchup.com/embed.html?mid=ef39a7d5-911b-4618-a48a-1f5d09757489&width=580&height=326" frameborder="0" scrolling="no" marginheight="0" marginwidth="0" width="580" height="326" allowfullscreen></iframe></html> | ||

[https://3dwarehouse.sketchup.com/model.html?id=ef39a7d5-911b-4618-a48a-1f5d09757489 Link to Google Warehouse] | [https://3dwarehouse.sketchup.com/model.html?id=ef39a7d5-911b-4618-a48a-1f5d09757489 Link to Google Warehouse] to download Sketchup file. | ||

'''Wanted: conversion to FreeCAD native format.''' | |||

=BOM= | =BOM= | ||

| Line 8: | Line 34: | ||

[https://docs.google.com/spreadsheets/d/1DxVZlZE0Ky5eLrOL2lcxCfL6yHJLP_iRlZApJ4uzfqM/edit#gid=0 edit] | [https://docs.google.com/spreadsheets/d/1DxVZlZE0Ky5eLrOL2lcxCfL6yHJLP_iRlZApJ4uzfqM/edit#gid=0 edit] | ||

<html><iframe src="https://docs.google.com/spreadsheets/d/1DxVZlZE0Ky5eLrOL2lcxCfL6yHJLP_iRlZApJ4uzfqM/pubhtml?widget=true&headers=false"></iframe></html> | <html><iframe src="https://docs.google.com/spreadsheets/d/1DxVZlZE0Ky5eLrOL2lcxCfL6yHJLP_iRlZApJ4uzfqM/pubhtml?widget=true&headers=false" width=1200 height=700></iframe></html> | ||

=Development= | |||

Published the latest design in Sketchup below | |||

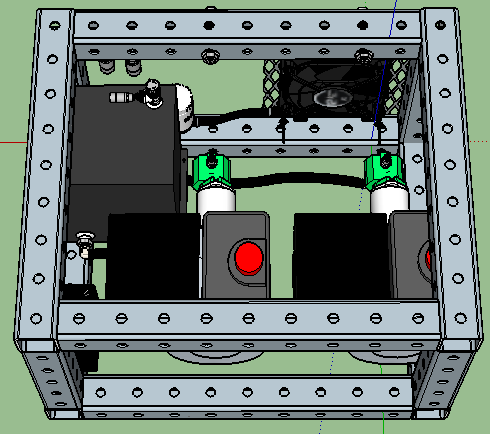

[[image:PC16.8.png|Power Cube 16.8|600px]] | |||

This design has had few updates lately. Here are the latest updates: | |||

Aug 2016: Twin 18HP engine design in the works - mostly complete, will be built in the September Power Cube workshop | |||

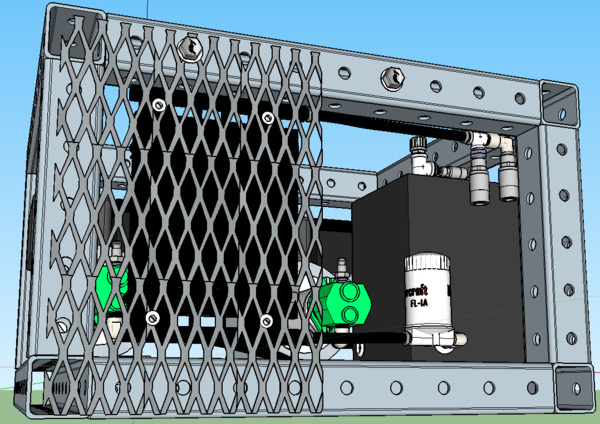

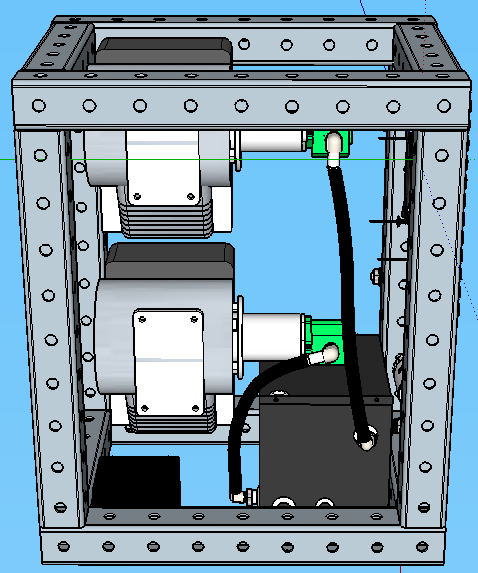

Snapshot: Hydraulic ports - 2 3/4" male outputs from the top of the pumps, 2 3/4" female returns and 1 1/4" low pressure return. | |||

[[Image:PC16.8HydraulicPorts.png Hydraulic Ports|600px]] | |||

Shapshot: Suction plumbing: Use 2 suction strainers and separate hoses to pumps, as reservoir ports are only 1 1/4" and these suction strainers are only rated at 8GPM each. | |||

[[Image:PC16.8SuctionPlumbing.png Suction Plumbing|600px]] | |||

==Question== | |||

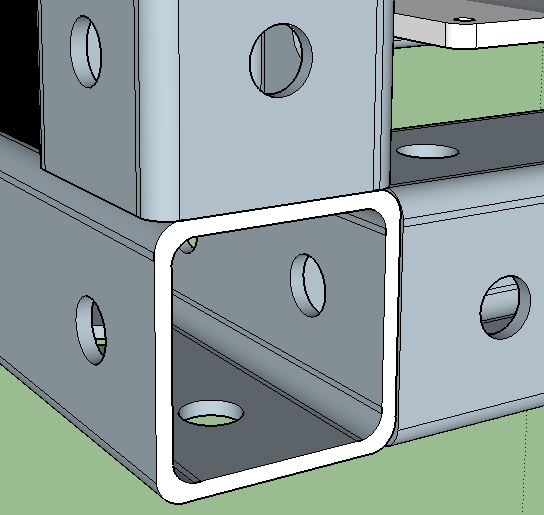

How should corners be formed and welded for optimal strength? Here is one image of a corner, with one of the horizontal members in the corner and the others welded to it: | |||

[[Image:PC16.8Corner.png Corner|600px]] | |||

Should the orientation be the same for all 8 corners? | |||

Should we employ any special grinding / welding procedures for the one weld where all three members meet? | |||

==Files== | |||

This is the 16.8 release. See file revision history for other versions. | |||

'''Bill Of Materials''' (BOM): [https://docs.google.com/spreadsheets/d/1DxVZlZE0Ky5eLrOL2lcxCfL6yHJLP_iRlZApJ4uzfqM/edit#gid=0 Power Cube BOM] | |||

* Duromax Engine Specs (with line drawings) [[File:DuromaxEngineSpecs.pdf]] | |||

'''Power Cube Working Document''': ["https://docs.google.com/spreadsheets/d/1DxVZlZE0Ky5eLrOL2lcxCfL6yHJLP_iRlZApJ4uzfqM/edit#gid=0"] | |||

'''Wiring Diagram''': [[File:PC16.8WiringDiagram.dia Wiring Diagram]] | |||

==Formulas== | |||

===Hydraulic Flow=== | |||

Pump displacement: 0.677 Cubic inches / Revolution (CIPR) | |||

Engine max speed: 3600 RPM | |||

Flow per engine/pump: 3600 * 0.677 / 231 = 10.55 GPM | |||

Total Flow: 21.1 GPM | |||

=Links= | |||

*[[Power Cube Design Guide]] | |||

*[[Power Cube]] | |||

Latest revision as of 08:51, 6 February 2021

3D Image

3D Manipulable file in Sketchup:

- Note: this needs to be converted from its proprietary Sketchup format into FreeCAD for editing, and WebGL for embedding.

Presentation

Muffler

Design Review

Note: v16.09 denotes the month/year of active development on the Power Cube, according to OSE naming standards.

Design

Link to Google Warehouse to download Sketchup file.

Wanted: conversion to FreeCAD native format.

BOM

Development

Published the latest design in Sketchup below

This design has had few updates lately. Here are the latest updates:

Aug 2016: Twin 18HP engine design in the works - mostly complete, will be built in the September Power Cube workshop

Snapshot: Hydraulic ports - 2 3/4" male outputs from the top of the pumps, 2 3/4" female returns and 1 1/4" low pressure return.

Shapshot: Suction plumbing: Use 2 suction strainers and separate hoses to pumps, as reservoir ports are only 1 1/4" and these suction strainers are only rated at 8GPM each.

Question

How should corners be formed and welded for optimal strength? Here is one image of a corner, with one of the horizontal members in the corner and the others welded to it:

Should the orientation be the same for all 8 corners?

Should we employ any special grinding / welding procedures for the one weld where all three members meet?

Files

This is the 16.8 release. See file revision history for other versions.

Bill Of Materials (BOM): Power Cube BOM

- Duromax Engine Specs (with line drawings) File:DuromaxEngineSpecs.pdf

Power Cube Working Document: ["https://docs.google.com/spreadsheets/d/1DxVZlZE0Ky5eLrOL2lcxCfL6yHJLP_iRlZApJ4uzfqM/edit#gid=0"]

Wiring Diagram: File:PC16.8WiringDiagram.dia Wiring Diagram

Formulas

Hydraulic Flow

Pump displacement: 0.677 Cubic inches / Revolution (CIPR) Engine max speed: 3600 RPM Flow per engine/pump: 3600 * 0.677 / 231 = 10.55 GPM Total Flow: 21.1 GPM