Drive mechanism selection: Difference between revisions

Jump to navigation

Jump to search

(Created page with "=Linear motion= To achieve motion in a straight line, consider the following solutions in relation to the factors that are relevant to your application. {| class="wikitable"...") |

|||

| Line 5: | Line 5: | ||

! Application factors !! Belt drives !! Chain drives !! Rack/Gear and pinion !! Roller Pinon/rack !! Leadscrews !! Ballscrews !! Linear Motors | ! Application factors !! Belt drives !! Chain drives !! Rack/Gear and pinion !! Roller Pinon/rack !! Leadscrews !! Ballscrews !! Linear Motors | ||

|- | |- | ||

| Accuracy || Low || Low || Low-High || High || Low || Low-High || High | | '''Accuracy''' || Low || Low || Low-High || High || Low || Low-High || High | ||

|- | |- | ||

| Backlash/Vibration || A consideration || A consideration || A consideration || Near Zero || A consideration || A consideration || Near Zero | | '''Backlash/Vibration''' || A consideration || A consideration || A consideration || Near Zero || A consideration || A consideration || Near Zero | ||

|- | |- | ||

| Acceleration || Medium || Low || High || High || Low || Medium || High | | '''Acceleration''' || Medium || Low || High || High || Low || Medium || High | ||

|- | |- | ||

| Speed || Medium || Low || Medium || High || Low || Medium || High | | '''Speed''' || Medium || Low || Medium || High || Low || Medium || High | ||

|- | |- | ||

| Load capacity || Low || Medium || High || High || Low || High || Low | | '''Load capacity''' || Low || Medium || High || High || Low || High || Low | ||

|- | |- | ||

| Length || Shorter || Shorter || Long || Long || Shorter || Shorter || Moderate | | '''Length''' || Shorter || Shorter || Long || Long || Shorter || Shorter || Moderate | ||

|- | |- | ||

| High wear and short life || A consideration || A consideration || A consideration || Long life || A consideration || A consideration || Long life | | '''High wear and short life''' || A consideration || A consideration || A consideration || Long life || A consideration || A consideration || Long life | ||

|- | |- | ||

| Maintenance || A consideration || A consideration || A consideration || Low to none || A consideration || A consideration || Low to none | | '''Maintenance''' || A consideration || A consideration || A consideration || Low to none || A consideration || A consideration || Low to none | ||

|- | |- | ||

| Noise level || Medium || High || Medium || Low || High || Medium || Low | | '''Noise level''' || Medium || High || Medium || Low || High || Medium || Low | ||

|- | |- | ||

| Dust and dirt emissions || High || High || Moderate || Low to none || Moderate || Moderate || Low to none | | '''Dust and dirt emissions''' || High || High || Moderate || Low to none || Moderate || Moderate || Low to none | ||

|} | |} | ||

Revision as of 15:30, 23 May 2021

Linear motion

To achieve motion in a straight line, consider the following solutions in relation to the factors that are relevant to your application.

| Application factors | Belt drives | Chain drives | Rack/Gear and pinion | Roller Pinon/rack | Leadscrews | Ballscrews | Linear Motors |

|---|---|---|---|---|---|---|---|

| Accuracy | Low | Low | Low-High | High | Low | Low-High | High |

| Backlash/Vibration | A consideration | A consideration | A consideration | Near Zero | A consideration | A consideration | Near Zero |

| Acceleration | Medium | Low | High | High | Low | Medium | High |

| Speed | Medium | Low | Medium | High | Low | Medium | High |

| Load capacity | Low | Medium | High | High | Low | High | Low |

| Length | Shorter | Shorter | Long | Long | Shorter | Shorter | Moderate |

| High wear and short life | A consideration | A consideration | A consideration | Long life | A consideration | A consideration | Long life |

| Maintenance | A consideration | A consideration | A consideration | Low to none | A consideration | A consideration | Low to none |

| Noise level | Medium | High | Medium | Low | High | Medium | Low |

| Dust and dirt emissions | High | High | Moderate | Low to none | Moderate | Moderate | Low to none |

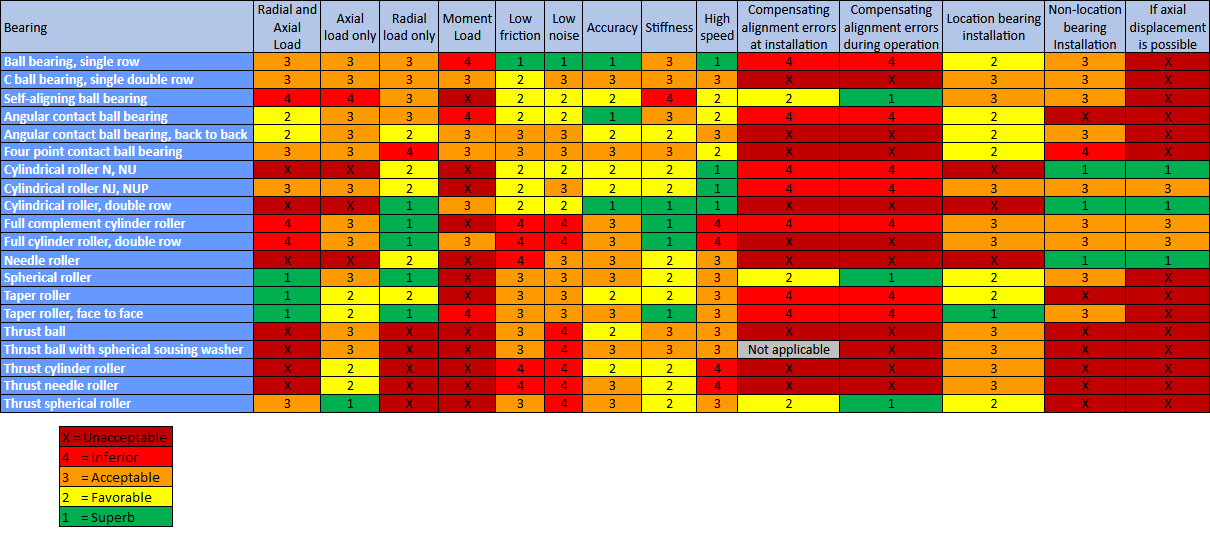

Rotary motion

For applications with heavy loads and slow turning, such as rotation of a crane, slewing bearings are suitable.

For applications with several, or several thousand, rotations per minute, rolling bearings are suitable.

Rolling bearings

Main article: Bearing selection

The table below shows level of suitability of different bearing types for different conditions.

This section is based on a table found in SKF handbooks and on the Engineers Edge website.

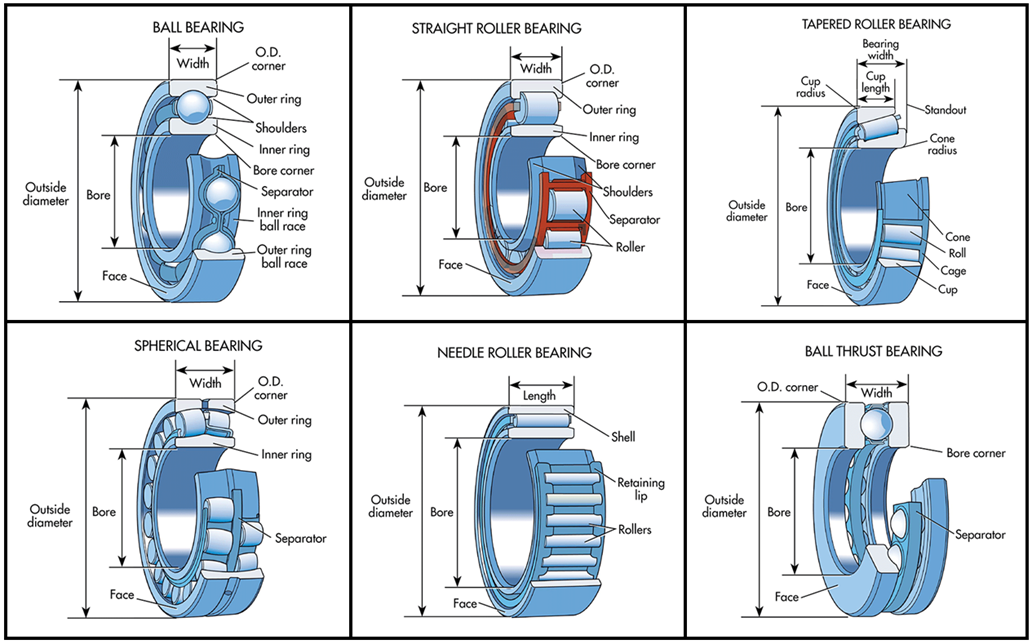

Image source: https://www.machinedesign.com/learning-resources/whats-the-difference-between/article/21831901/whats-the-difference-between-bearings

Image source: https://www.machinedesign.com/learning-resources/whats-the-difference-between/article/21831901/whats-the-difference-between-bearings