Drive mechanism selection: Difference between revisions

No edit summary |

|||

| Line 45: | Line 45: | ||

[[File:Bearing types.png|500]] | [[File:Bearing types.png|500]] | ||

Image source: https://www.machinedesign.com/learning-resources/whats-the-difference-between/article/21831901/whats-the-difference-between-bearings | Image source: https://www.machinedesign.com/learning-resources/whats-the-difference-between/article/21831901/whats-the-difference-between-bearings | ||

=Motors= | |||

A motor converts one form of energy into mechanical energy. | |||

==Summary== | |||

Servo motors are suitable for high speed and high acceleration requirements. The trade-off is a higher cost and complexity. | |||

Stepper motors are suitable for low speed and low acceleration requirements. | |||

DC motors are suitable for continuous rotation at high RPMs and constant torque across the motor’s speed range. | |||

==Stepper motors== | |||

'''Pros''' | |||

* High accuracy: A stepper motor enables rotational motion in incremental steps. This makes stepper motors suitable for applications that require precise motion. It also eliminates the need for an encoder (which is used to tell the motors precision.) | |||

* High torque at low speeds. | |||

* Relatively inexpensive and widely available. | |||

* Compact. | |||

* Easily controlled (can be controlled with micro controllers such as the ATmega chips that are readily available on Arduino development boards.) | |||

'''Cons''' | |||

* Speed limitations; loses most of their torque at high speeds, sometime up to 80%. | |||

* High vibrations levels and proneness to resonance issues. | |||

* Low efficiency; unlike DC motors, stepper motors constantly draw maximum current independent of load. | |||

* Produce high amounts of heat. | |||

* Can stall or lose position without a control loop. | |||

* Load limitations; might skip steps at high loads. | |||

'''Suitable applications''' | |||

* valve pilot stages for fluid control systems. | |||

* floppy disk drives | |||

* flatbed scanners | |||

* computer printers | |||

* plotters | |||

* slot machines | |||

* image scanners | |||

* compact disc drives | |||

* intelligent lighting | |||

* camera lenses | |||

* CNC machines and 3D printers. | |||

* Textile machines | |||

* Printing presses | |||

* Medical imaging machinery | |||

* Small robotics | |||

* Welding equipment | |||

==Servo motors== | |||

'''Pros''' | |||

* High accuracy; achieved by adding encoder to the system. | |||

* High speed; can maintain high torque at high speed (unlike stepper motors.) | |||

* High efficiency; 80–90% efficiency. | |||

* Does not suffer from vibration or resonance issues. | |||

* Low noise levels at high speeds. | |||

* Servo motors can work in AC or DC drive. | |||

'''Cons''' | |||

* May require an encoder and gearbox (which makes the system more expensive). | |||

* Requires more maintenance (if the system includes more parts) | |||

* Limited range of motion; positional rotation servos are limited to 180 degrees of motion. | |||

'''Suitable applications''' | |||

==Brushed DC Motors== | |||

'''Pros''' | |||

* aaa | |||

'''Cons''' | |||

* High maintenance requirements due to easily worn out as a result of continuous moving contact. | |||

* Speed limitations due to brush heating. | |||

==Brushless DC Motors== | |||

'''Pros''' | |||

* aaa | |||

'''Cons''' | |||

* Low maintenance requirements. | |||

* Some brushless motors are difficult to control and require a specialized regulator | |||

Revision as of 14:50, 24 May 2021

Linear motion

Linear motion is motion in a straight line. It is usually achieved by converting rotational motion to linear motion - such is the case for belt drives, ball screws, etc. but not for linear motors.

To achieve linear motion, consider the following solutions in relation to the factors that are relevant to your application.

| Application factors | Belt drives | Chain drives | Rack/Gear and pinion | Roller Pinon/rack | Leadscrews | Ballscrews | Linear Motors |

|---|---|---|---|---|---|---|---|

| Accuracy | Low | Low | Low-High | High | Low | Low-High | High |

| Backlash/Vibration | A consideration | A consideration | A consideration | Near Zero | A consideration | A consideration | Near Zero |

| Acceleration | Medium | Low | High | High | Low | Medium | High |

| Speed | Medium | Low | Medium | High | Low | Medium | High |

| Load capacity | Low | Medium | High | High | Low | High | Low |

| Length | Shorter | Shorter | Long | Long | Shorter | Shorter | Moderate |

| High wear and short life | A consideration | A consideration | A consideration | Long life | A consideration | A consideration | Long life |

| Maintenance | A consideration | A consideration | A consideration | Low to none | A consideration | A consideration | Low to none |

| Noise level | Medium | High | Medium | Low | High | Medium | Low |

| Dust and dirt emissions | High | High | Moderate | Low to none | Moderate | Moderate | Low to none |

Rotary motion

For applications with heavy loads and slow turning, such as rotation of a crane, slewing bearings are suitable.

For applications with several, or several thousand, rotations per minute, rolling bearings are suitable.

Rolling bearings

Main article: Bearing selection

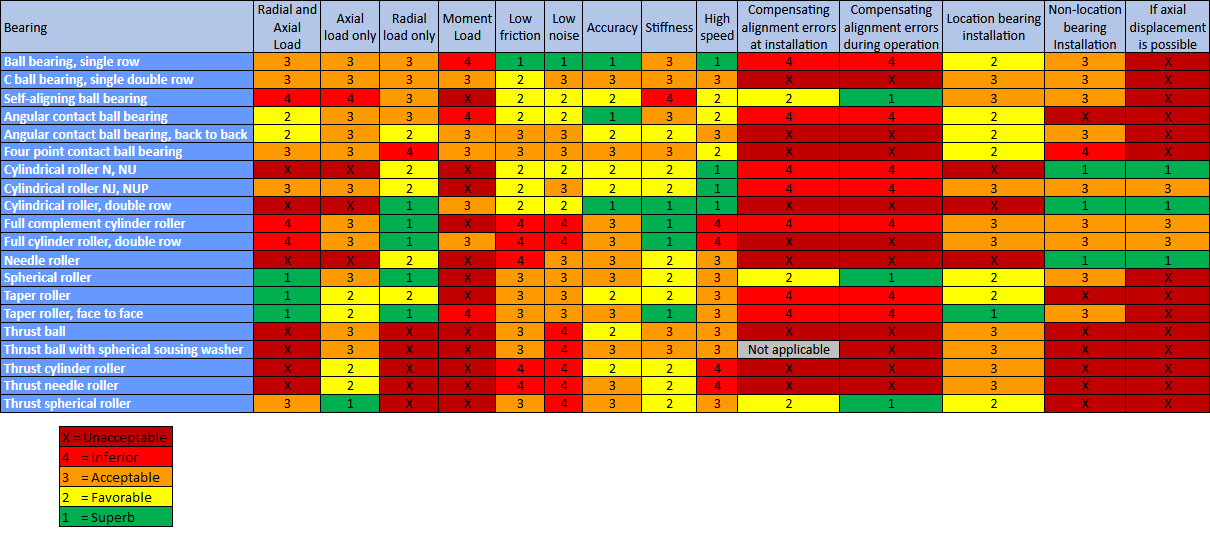

The table below shows level of suitability of different bearing types for different conditions.

This section is based on a table found in SKF handbooks and on the Engineers Edge website.

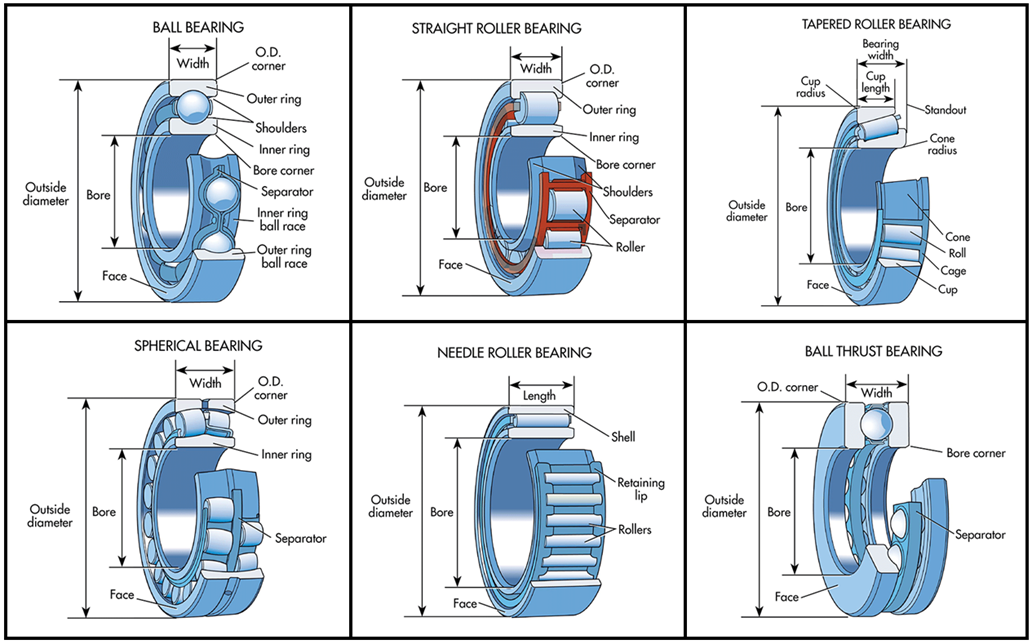

Image source: https://www.machinedesign.com/learning-resources/whats-the-difference-between/article/21831901/whats-the-difference-between-bearings

Image source: https://www.machinedesign.com/learning-resources/whats-the-difference-between/article/21831901/whats-the-difference-between-bearings

Motors

A motor converts one form of energy into mechanical energy.

Summary

Servo motors are suitable for high speed and high acceleration requirements. The trade-off is a higher cost and complexity. Stepper motors are suitable for low speed and low acceleration requirements. DC motors are suitable for continuous rotation at high RPMs and constant torque across the motor’s speed range.

Stepper motors

Pros

- High accuracy: A stepper motor enables rotational motion in incremental steps. This makes stepper motors suitable for applications that require precise motion. It also eliminates the need for an encoder (which is used to tell the motors precision.)

- High torque at low speeds.

- Relatively inexpensive and widely available.

- Compact.

- Easily controlled (can be controlled with micro controllers such as the ATmega chips that are readily available on Arduino development boards.)

Cons

- Speed limitations; loses most of their torque at high speeds, sometime up to 80%.

- High vibrations levels and proneness to resonance issues.

- Low efficiency; unlike DC motors, stepper motors constantly draw maximum current independent of load.

- Produce high amounts of heat.

- Can stall or lose position without a control loop.

- Load limitations; might skip steps at high loads.

Suitable applications

- valve pilot stages for fluid control systems.

- floppy disk drives

- flatbed scanners

- computer printers

- plotters

- slot machines

- image scanners

- compact disc drives

- intelligent lighting

- camera lenses

- CNC machines and 3D printers.

- Textile machines

- Printing presses

- Medical imaging machinery

- Small robotics

- Welding equipment

Servo motors

Pros

- High accuracy; achieved by adding encoder to the system.

- High speed; can maintain high torque at high speed (unlike stepper motors.)

- High efficiency; 80–90% efficiency.

- Does not suffer from vibration or resonance issues.

- Low noise levels at high speeds.

- Servo motors can work in AC or DC drive.

Cons

- May require an encoder and gearbox (which makes the system more expensive).

- Requires more maintenance (if the system includes more parts)

- Limited range of motion; positional rotation servos are limited to 180 degrees of motion.

Suitable applications

Brushed DC Motors

Pros

- aaa

Cons

- High maintenance requirements due to easily worn out as a result of continuous moving contact.

- Speed limitations due to brush heating.

Brushless DC Motors

Pros

- aaa

Cons

- Low maintenance requirements.

- Some brushless motors are difficult to control and require a specialized regulator