Solar Thermal Electrical Generation: Difference between revisions

No edit summary |

|||

| Line 3: | Line 3: | ||

We are building a solar thermal concentrator electrical generation system prototype at Factor e Farm, starting in mid August. We have a Google group organized around this, and a development wiki [http://openfarmtech.org/index.php?title=Solar_Turbine_Prototype_at_Factor_e_Farm here]. | We are building a solar thermal concentrator electrical generation system prototype at Factor e Farm, starting in mid August. We have a Google group organized around this, and a development wiki [http://openfarmtech.org/index.php?title=Solar_Turbine_Prototype_at_Factor_e_Farm here]. | ||

Some of the highlights are | Some of the highlights are shown in the description below | ||

(Linked from [[Solar_Turbine]]) | (Linked from [[Solar_Turbine]]) | ||

Revision as of 15:29, 6 August 2008

Introduction

We are building a solar thermal concentrator electrical generation system prototype at Factor e Farm, starting in mid August. We have a Google group organized around this, and a development wiki here.

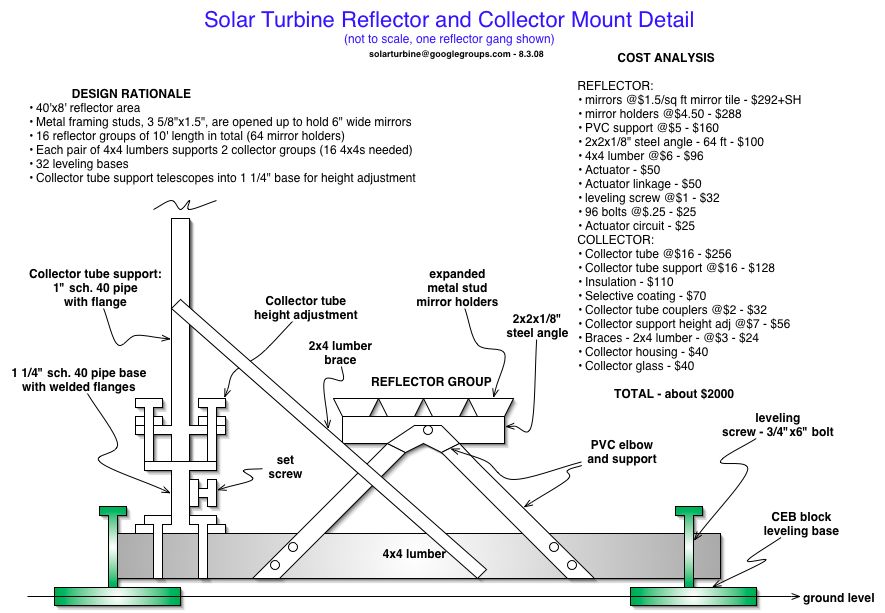

Some of the highlights are shown in the description below

(Linked from Solar_Turbine)

Email Group

Join the Solar Turbine email group

Introduction

We are building a replicable solar thermal concentrator electric power system - on the kW scale. The closest system that we found to our design is:

Source. We should identify and contact the designers.

Design Drawings

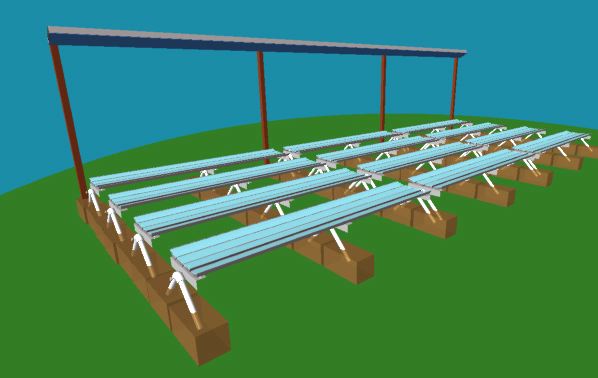

The site will be prepared by leveling with a tractor and blade. We are building on the conceptual drawings in Solar Concentrators and Solar_Concentrator_Technical_Drawings:

- Solar Concentrator Foundation - CEB posts are presently our first choice, but we may revert to lumber if technical difficulties arise

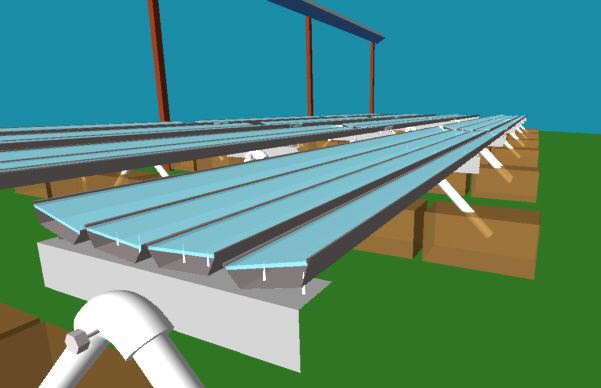

- Concentrator Structure - collector tube mounting, slat mounting, connecting posts together

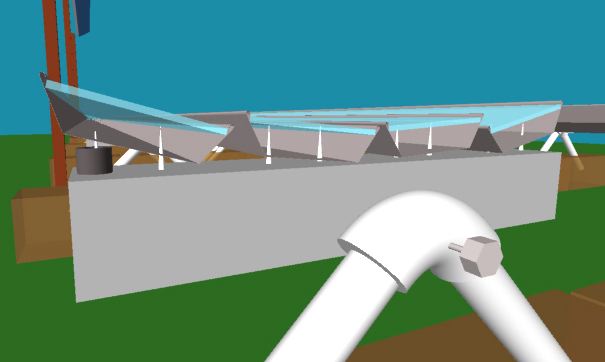

- Mirror Slats - rotation support bearing, bearing mounts, rod, slats, mechanical fasteners

- Tracking - sensor, actuator, gearing

- Solar Concentrator Tube - glazing, insulation and cover, tubing connection, attachment to support structure, alignment mechanism

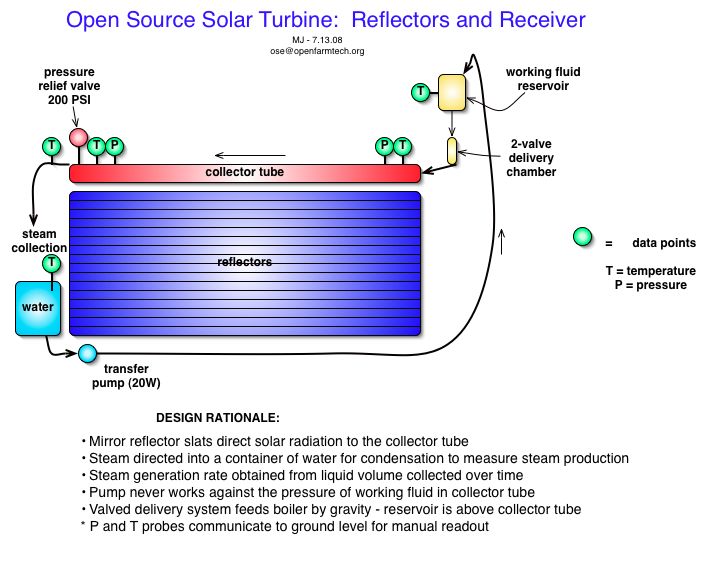

Reflectors, Collector, and Data Acquisition

Overview. Steam is our preferred choice due to its simplicity. I am not sure whether steam will yield the highest efficiency, but we can optimize this point by going to higher temperatures. Advantage: a sustainable resource. Disadvantage: freezes in winter

Updated Designs

Here is an updated proposition from Ben, end of July, 2008:

Marcin proposes the following implementation:

Part Sourcing Information

Here are some prices that I found out. Please submit others:

- Mirror

- $291 plus shipping - for 360 pieces of 12x10" tile - [1]

- Menards has mirror tile at $1.5/sq ft

- Aluminized Mylar - $40 - for thin 1 mil - [2]

- Mirror holders - steel studs, which can be opened up to the 6" width of the mirrors to be held - are structurally sound and relatively inexpensive

- Menards has 3 5/8"x1 1/2" steel studs, 10 foot long, for $4.50

- Others?

- Selective solar coating - $70/gallon from Solec

- Foundation

- CEB block & 6 tons of gravel - gravel for $150

- 4x4s may be utilized with Ben's updated design - [3]

- Collector tube:

- 16 10 foot sections of 1" galvanized pipe - $16 each, $256

- 8 more of the above for collector tube supports - $128

- Insulation - [4] - $110

- Other:

- Bearings for reflector slats - $30 for 100 at vxb.com, need 160 for total of $60

- 10' of 1/2" Electric Mechanical Tube, galvanized steel - $2.89 at Menards, need 16, total of $48

- 3/8" rod, 6', $10 at McMaster Carr, Part # 9120K64, need 26, total of $260

- 107 sq ft of gauge 18 steel sheet, $2/sq ft at 7.11.08 prices - $214

Background Calculations

It is extremely useful - in order to gain an appreciation of the power available from solar energy - to go through the basic calculations of power yields from our system, and to compare those yields to the energy obtainable from sustainably-harvested biomass energy. See these notes here.