Solar Thermal Electrical Generation: Difference between revisions

No edit summary |

|||

| Line 5: | Line 5: | ||

Some of the highlights are shown in the description below | Some of the highlights are shown in the description below | ||

=Research Areas= | |||

Key developments involve: | |||

*Reflector structure optimization - lighweight, low-cost support structure is needed | |||

*Tracking system - accurate daily tracking is needed - [http://www.redrok.com/electron.htm#led3x RedRok] tracker may need improvement | |||

*Collector structure optimization - minimize reflective, conductive, emissivity losses | |||

*Steam engine development - digital fabrication molding, casting, and machining of modern steam engine | |||

*Steam cycle optimization of temperature, pressure, cooling, preheating, and energy regeneration regimes | |||

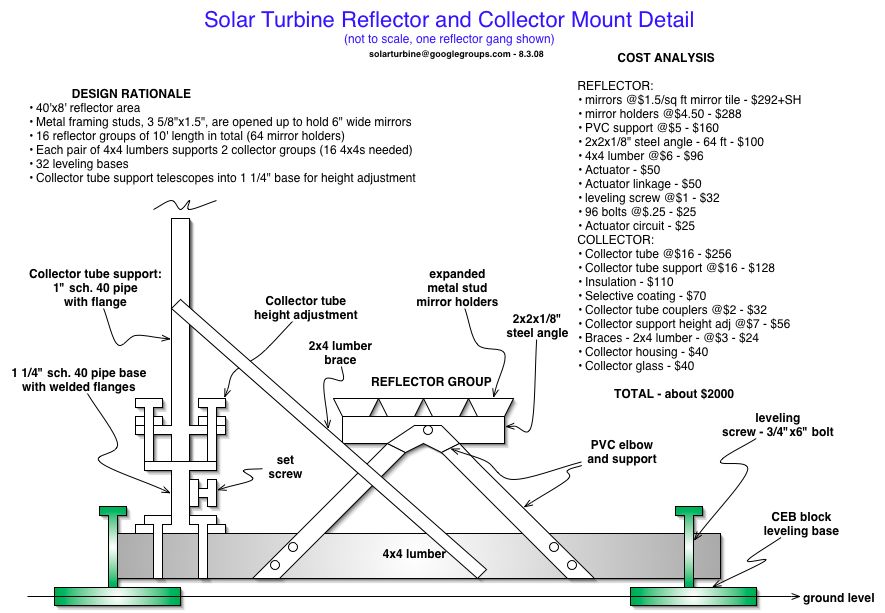

Based on the outcomes of the August prototype, we will continue. Presently, we need to procure a heat engine and test the fabrication procedure of collector/reflector structure to verify cost predictions of $1950 for a 30kW solar intercept system that generates between 500 and 3500 watts of electrical power. | |||

=Email Group= | =Email Group= | ||

| Line 48: | Line 58: | ||

[[Image:ganged_frame.jpg]] | [[Image:ganged_frame.jpg]] | ||

=Additional Information= | =Additional Information= | ||

See [[Solar_Turbine]] | See [[Solar_Turbine]] | ||

[[Categogy:Research_Topics]] | [[Categogy:Research_Topics]] | ||

Revision as of 15:37, 6 August 2008

Introduction

We are building a solar thermal concentrator electrical generation system prototype at Factor e Farm, starting in mid August. We have a Google group organized around this, and a development wiki here.

Some of the highlights are shown in the description below

Research Areas

Key developments involve:

- Reflector structure optimization - lighweight, low-cost support structure is needed

- Tracking system - accurate daily tracking is needed - RedRok tracker may need improvement

- Collector structure optimization - minimize reflective, conductive, emissivity losses

- Steam engine development - digital fabrication molding, casting, and machining of modern steam engine

- Steam cycle optimization of temperature, pressure, cooling, preheating, and energy regeneration regimes

Based on the outcomes of the August prototype, we will continue. Presently, we need to procure a heat engine and test the fabrication procedure of collector/reflector structure to verify cost predictions of $1950 for a 30kW solar intercept system that generates between 500 and 3500 watts of electrical power.

Email Group

Join the Solar Turbine email group

Introduction

We are building a replicable solar thermal concentrator electric power system - on the kW scale. The closest system that we found to our design is:

Source. We should identify and contact the designers.

Design Drawings

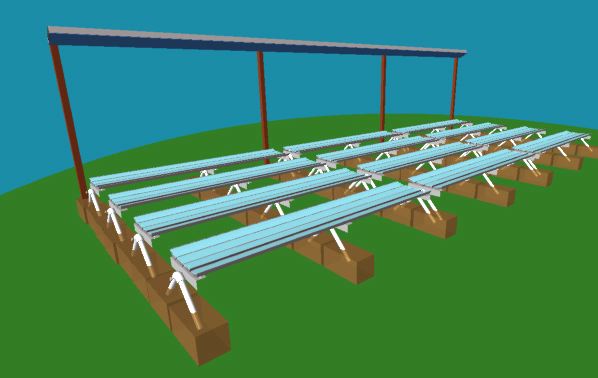

The site will be prepared by leveling with a tractor and blade. We are building on the conceptual drawings in Solar Concentrators and Solar_Concentrator_Technical_Drawings:

- Solar Concentrator Foundation - CEB posts are presently our first choice, but we may revert to lumber if technical difficulties arise

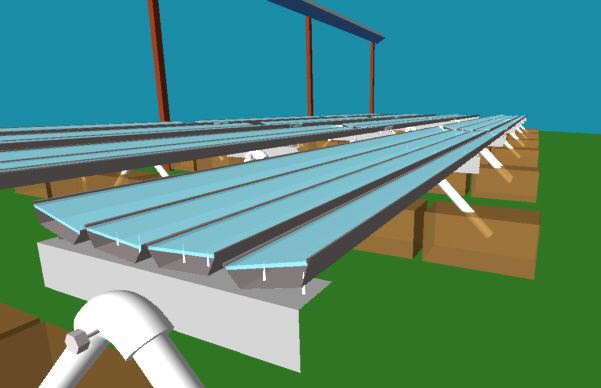

- Concentrator Structure - collector tube mounting, slat mounting, connecting posts together

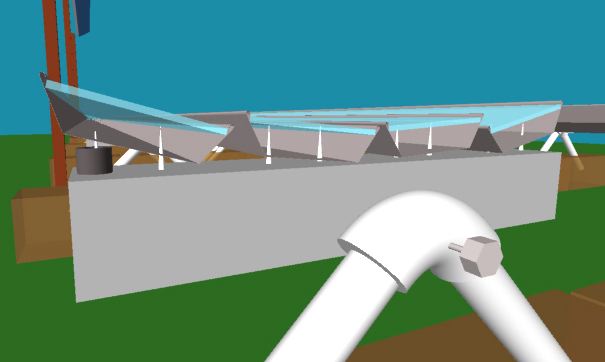

- Mirror Slats - rotation support bearing, bearing mounts, rod, slats, mechanical fasteners

- Tracking - sensor, actuator, gearing

- Solar Concentrator Tube - glazing, insulation and cover, tubing connection, attachment to support structure, alignment mechanism

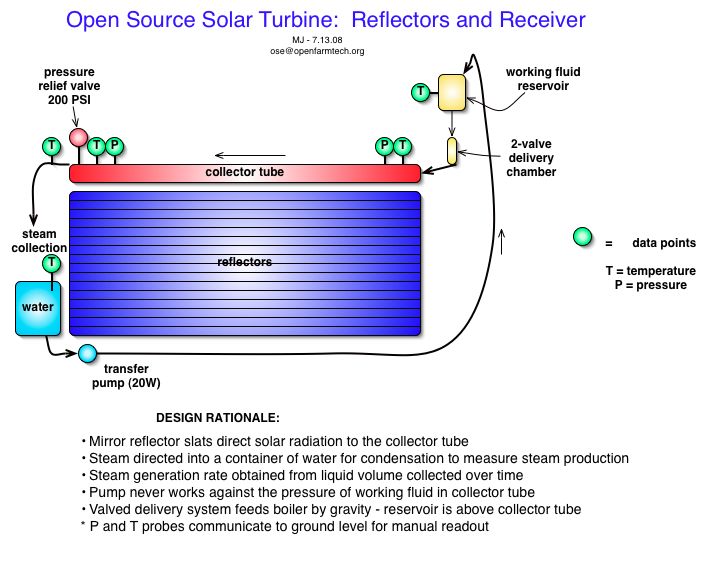

Reflectors, Collector, and Data Acquisition

Overview. Steam is our preferred choice due to its simplicity. I am not sure whether steam will yield the highest efficiency, but we can optimize this point by going to higher temperatures. Advantage: a sustainable resource. Disadvantage: freezes in winter

Updated Designs

Here is an updated proposition from Ben, end of July, 2008:

Marcin proposes the following implementation:

Additional Information

See Solar_Turbine