OSE Shop 2011 Interface Plate: Difference between revisions

No edit summary |

No edit summary |

||

| (4 intermediate revisions by the same user not shown) | |||

| Line 1: | Line 1: | ||

{{Hint|Not clear what exactly this is but if 8'+, it's a standard columnar support for a large interior space, such as industrial. Not clear how many columns for the BOM or size of structure. Looks like a a 5x5 grid (26 columns)}} | |||

=About= | |||

[[File:InterfaceAssembly.png|800px]] | [[File:InterfaceAssembly.png|800px]] | ||

| Line 20: | Line 24: | ||

It may be possible to use rebar instead of tubing for the central link | It may be possible to use rebar instead of tubing for the central link | ||

=Review= | |||

*Instead of 6x6 tube, use 3/4" rebar welded to top and bottom plates | |||

*Sufficient for bottom plate to be a square 1/4"x12"x12" - because it's a monolithic column | |||

*Top plate - 1' may be sufficient - just enough to attach the beams | |||

*use 3/16"x2"x6" rectangular tubing, slit in half - to produce the u-brackets - no welding, just bandsaw | |||

*Torch a hole through top plate for conduit | |||

[[Category:OSE Shop]] | [[Category:OSE Shop]] | ||

Latest revision as of 05:52, 24 June 2024

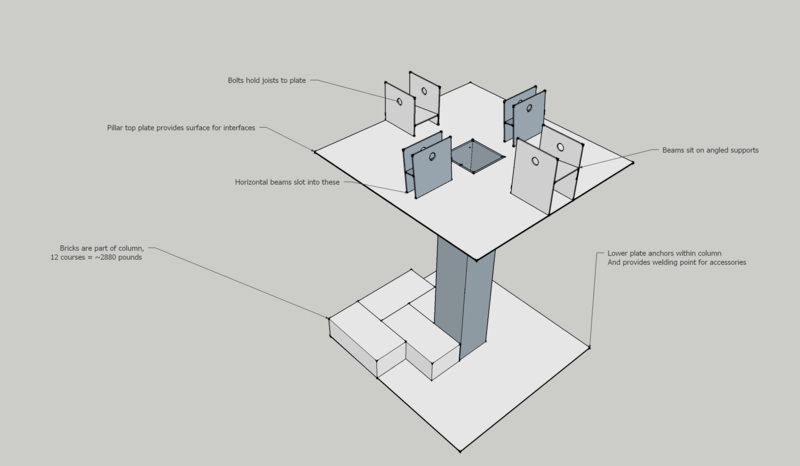

![]() Hint: Not clear what exactly this is but if 8'+, it's a standard columnar support for a large interior space, such as industrial. Not clear how many columns for the BOM or size of structure. Looks like a a 5x5 grid (26 columns)

Hint: Not clear what exactly this is but if 8'+, it's a standard columnar support for a large interior space, such as industrial. Not clear how many columns for the BOM or size of structure. Looks like a a 5x5 grid (26 columns)

About

This is made of steel and has over 12 feet of welding bead required to assemble each of them

There is a variant used at the roof peak, but it uses no unique parts.

The structures require 5 peak and up to 21 pitched assemblies. (6 for expanded storage)

That means material cost of the parts fabrication:

52 2.5'x2.5' steel plates 26 6"x6"x3' steel square tubing 104 angle plates 6x6x1/8" 104 beam plates 6x6x1/8" 52 angle support plates 1.5"x6"x1/8" 52 beam support plates 4.5"x6"x1/8" 312 linear welding feet

It may also be appropriate to weld the top plates on manually to match the vagrancies of CEB spacing

It may be possible to use rebar instead of tubing for the central link

Review

- Instead of 6x6 tube, use 3/4" rebar welded to top and bottom plates

- Sufficient for bottom plate to be a square 1/4"x12"x12" - because it's a monolithic column

- Top plate - 1' may be sufficient - just enough to attach the beams

- use 3/16"x2"x6" rectangular tubing, slit in half - to produce the u-brackets - no welding, just bandsaw

- Torch a hole through top plate for conduit