Civilization Systems Engineering: Difference between revisions

Tag: Reverted |

|||

| (13 intermediate revisions by the same user not shown) | |||

| Line 5: | Line 5: | ||

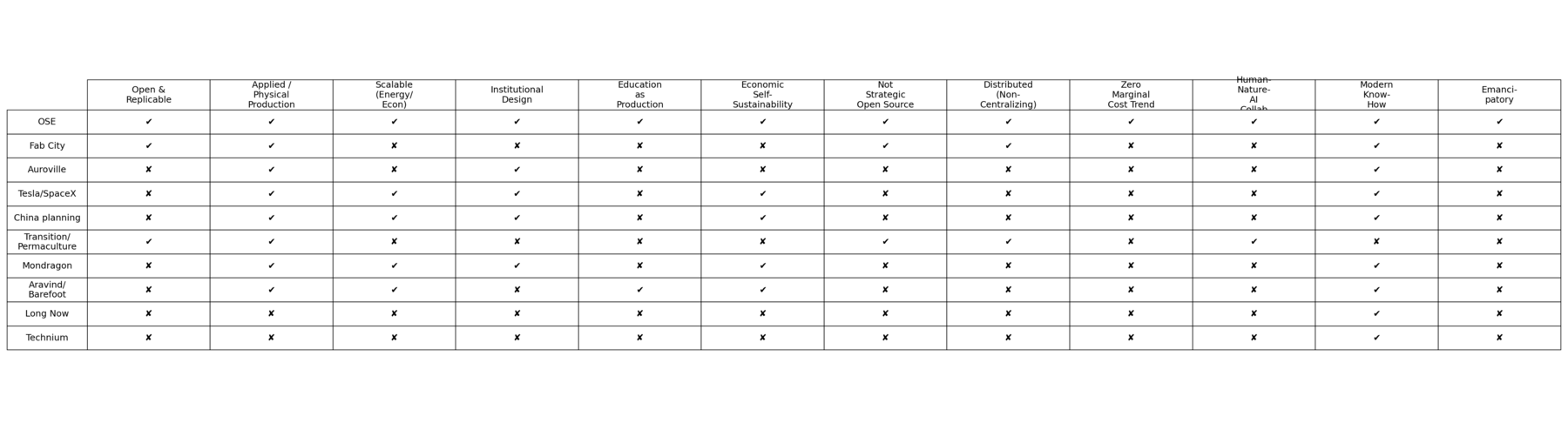

Take a look at a table of existing industry standards in the field - [https://chatgpt.com/share/696413d3-84e8-8010-a36d-506c23ec1f2e]: | Take a look at a table of existing industry standards in the field - [https://chatgpt.com/share/696413d3-84e8-8010-a36d-506c23ec1f2e]: | ||

[[File:civengineeringefforts.png| | [[File:civengineeringefforts.png|1800 px]] | ||

=Curriculum Development= | |||

Interesting discussion starts with Lean, goes into the Toyota Production System, and culminates with the Fermi Paradox. | |||

<html> <iframe src="https://docs.google.com/document/d/e/2PACX-1vTON0foe7tKeQKyIDXhOYpGFfGp7a3n0dkZNb9rjph5KvXwGrq7nCilszhQz6WCSlHemCSITHg2qllS/pub?embedded=true" height=500 width=800></iframe> </html> | |||

[https://docs.google.com/document/d/1aL2QWLRGkwHdb6ve6E_rp-yVkLBpMUEBavB7vOx_5Xw/edit?tab=t.0 edit] | |||

=Discussion= | =Discussion= | ||

Source - [https://chatgpt.com/share/ | Source - [https://chatgpt.com/share/69642560-0920-8010-8549-90a5f38e44c2] | ||

PDF - | PDF - [[File:From_Lean_to_Fermi_Paradox.pdf]] | ||

=Reading List | =Reading List - Civilization Systems Engineering = | ||

This reading list is designed as a foundation course in Civilization Systems Engineering. It starts with Lean and the Toyota Production System (how to build efficiently), expands to systems engineering and complex systems design (how to architect integrated systems), then moves into civilization history, political economy, ecology/energy constraints, and finally civilization longevity questions (including Fermi-paradox-relevant considerations) and open/distributed production models. | This reading list is designed as a foundation course in Civilization Systems Engineering. It starts with Lean and the Toyota Production System (how to build efficiently), expands to systems engineering and complex systems design (how to architect integrated systems), then moves into civilization history, political economy, ecology/energy constraints, and finally civilization longevity questions (including Fermi-paradox-relevant considerations) and open/distributed production models. | ||

| Line 78: | Line 85: | ||

# Explicitly connect the lineage to OSE’s understanding of designing “product ecologies and civilization architectures” that enable abundance and broad participation. | # Explicitly connect the lineage to OSE’s understanding of designing “product ecologies and civilization architectures” that enable abundance and broad participation. | ||

= | =Trasnscript= | ||

= Is there a book better than Eric Ries' ''The Lean Startup'' on the topic of lean? = | |||

Is there a book better than Eric Ries' The Lean Startup on the topic of lean? | |||

Yes — if your goal is to go | Yes — if your goal is to go beyond the high-level entrepreneurial framing of ''The Lean Startup'' and dive deeper into lean principles, history, culture, and practice, there are several books widely regarded as more substantive, foundational, or practical on lean thinking and implementation. | ||

and dive | |||

widely regarded as | Below are top recommended books depending on what aspect of “lean” you want to master: | ||

implementation | |||

Below are | == 1. Classic and Foundational Lean Thinking (Manufacturing & Management) == | ||

These books pre-date and in many ways underpin the Lean Startup approach — showing where the principles originally came from and how they scale to organizations. | |||

These books pre-date and | |||

the principles originally came from and how they scale to organizations. | === ''Lean Thinking: Banish Waste and Create Wealth in Your Corporation'' === | ||

* '''Authors:''' James P. Womack & Daniel T. Jones | |||

* '''Why it’s better (for lean principles):''' This is one of the most influential books on lean outside of Toyota, articulating the core lean principles like value definition, value stream mapping, flow, pull, and pursuit of perfection. | |||

* This book is broader and more prescriptive on enterprise-wide lean application than Ries’ startup focus. | |||

Toyota, articulating the | |||

pull, and pursuit of perfection. | === ''The Toyota Way: 14 Management Principles from the World’s Greatest Manufacturer'' === | ||

* '''Author:''' Jeffrey K. Liker | |||

startup focus. | * Explains Toyota’s management philosophy and culture, including kaizen, respect for people, long-term thinking, and continuous improvement. | ||

* Great if you want to understand why lean works beyond tools and metrics. | |||

=== ''The Machine That Changed the World'' === | |||

long-term thinking, and continuous improvement. | * '''Authors:''' James P. Womack, Daniel T. Jones, and Daniel Roos | ||

* A classic research-based history of Toyota’s development of lean production and its differentiation from craft and mass production systems. | |||

* It’s widely considered the definitive origin story of lean for manufacturing leaders. | |||

== 2. Practical Lean Implementation (Tools & Mindsets) == | |||

differentiation from craft and mass production systems. | |||

These focus less on high-level philosophy and more on day-to-day application and learning processes. | |||

=== ''Managing to Learn (A3 Thinking)'' === | |||

These focus less on high-level philosophy and more on | * '''Author:''' John Shook | ||

processes. | * Teaches the A3 problem-solving process — a foundational lean management method used by Toyota and lean practitioners globally. | ||

* Excellent if you want hands-on coaching tools and structured problem framing. | |||

by Toyota and lean practitioners globally. | === ''Toyota Way Fieldbook'' === | ||

* '''Authors:''' Jeffrey K. Liker & David Meier | |||

* A practical companion to ''The Toyota Way'', with tools, case studies, and detailed methods for applying TPS in your organization. | |||

=== ''Gemba Kaizen'' === | |||

for applying TPS in your organization. | * '''Author:''' Masaaki Imai | ||

* A classic on continuous improvement (kaizen) with actionable guidance from the shop floor up. | |||

* Good for understanding how to root lean in everyday work practices. | |||

up. | == 3. Complementary Reads to Expand Lean Startup Thinking == | ||

If you liked the strategy and organizational focus of Ries’ work, but want complementary perspectives: | |||

If you liked the strategy and organizational focus of Ries’ work, but want | === ''Running Lean'' === | ||

perspectives | * '''Author:''' Ash Maurya | ||

* Takes Lean Startup concepts and turns them into a step-by-step execution playbook — more tactical than ''The Lean Startup''. | |||

=== ''Lean Analytics'' === | |||

tactical than The Lean Startup | * '''Authors:''' Alistair Croll & Benjamin Yoskovitz | ||

* Deep dive into data-driven experimentation and metrics — helpful if your work emphasizes measuring learning outcomes. | |||

=== ''The Startup Owner’s Manual'' === | |||

* '''Authors:''' Steve Blank & Bob Dorf | |||

* Not strictly “lean” but offers comprehensive customer development and business model validation frameworks aligned with lean thinking. | |||

== Which One Is “Better Than ''The Lean Startup''”? == | |||

validation | |||

'''For lean as a discipline (not just startup methodology):''' | |||

* ''Lean Thinking'' and ''The Toyota Way'' are often considered more fundamental than ''The Lean Startup''. | |||

'''For practical implementation:''' | |||

Lean Startup | * ''Managing to Learn'' or ''Toyota Way Fieldbook'' provide tools you can use today. | ||

'''For startup execution beyond theory:''' | |||

* ''Running Lean'' and ''Lean Analytics'' will give you hands-on methods and measures that some readers find more actionable than Ries’ narrative. | |||

some readers find more actionable than Ries’ narrative. | |||

== Recommended Reading Path (Progressive) == | |||

# ''Lean Thinking'' (foundation in lean principles) | |||

# ''The Toyota Way'' (culture + management) | |||

# ''Managing to Learn / Toyota Way Fieldbook'' (tools + practice) | |||

# ''Running Lean / Lean Analytics'' (startup execution focus) | |||

This sequence takes you from | |||

tools → startup execution | This sequence takes you from foundational philosophy → cultural understanding → practical tools → startup execution. | ||

If you tell me whether you care most about | If you tell me whether you care most about startup execution, enterprise transformation, or manufacturing operations, I can tailor a reading list with specific short summaries and order. | ||

How does the | = How does the Toyota method relate to flexible manufacturing discussed in ''The Second Industrial Divide''? Is the latter also a seminal book in the field of lean? = | ||

Divide? Is the latter also a seminal book in the field of lean? | |||

Your question goes to the heart of how “lean” emerged historically—and how it differs from (and | Your question goes to the heart of how “lean” emerged historically—and how it differs from (and overlaps with) “flexible manufacturing” as analyzed in ''The Second Industrial Divide''. | ||

overlaps with) “flexible manufacturing” as analyzed in | |||

Below is a precise framing. | Below is a precise framing. | ||

== 1. What ''The Second Industrial Divide'' Is Actually About == | |||

'''Book:''' ''The Second Industrial Divide: Possibilities for Prosperity'' | |||

The book is not a “lean” manual. It is a | '''Authors:''' Michael Piore & Charles Sabel (1984) | ||

that contrasts two paradigms: | |||

The book is not a “lean” manual. It is a political-economic and industrial organization theory that contrasts two paradigms: | |||

=== A. Mass Production (First Industrial Divide) === | |||

* Fordist, large-batch, dedicated machinery | |||

* Vertical integration | |||

* Low variety, high volume | |||

* Hierarchical control | |||

=== B. Flexible Specialization (Second Industrial Divide) === | |||

* Small-batch, high-variety production | |||

Piore and Sabel’s core claim: | * General-purpose machinery (CNC, modular tooling) | ||

* Skilled labor, craft-like problem solving | |||

and innovation-driven. | * Networked firms, regional clusters (e.g., Emilia-Romagna in Italy) | ||

* Rapid reconfiguration of production systems | |||

Piore and Sabel’s core claim: | |||

''Advanced capitalism does not have to be mass production; it can be flexible, decentralized, and innovation-driven.'' | |||

Toyota’s system—later labeled | |||

systematized in: | == 2. What the Toyota Production System (TPS) Is About == | ||

Toyota’s system—later labeled “lean”—was developed earlier (1950s–1970s) and systematized in: | |||

* ''The Machine That Changed the World'' (1990) | |||

* ''Lean Thinking'' (1996) | |||

* ''The Toyota Way'' (2004) | |||

Its defining characteristics: | Its defining characteristics: | ||

* '''Just-in-Time''': flow, pull, takt | |||

* '''Jidoka''': built-in quality, stop-the-line | |||

* '''Kaizen''': continuous improvement | |||

* '''Standardized work + respect for people''' | |||

* '''Relentless waste elimination (muda)''' | |||

TPS is not primarily about craft production or decentralization; it is about | |||

excellence | TPS is not primarily about craft production or decentralization; it is about systematic operational excellence at scale. | ||

== 3. How TPS Relates to “Flexible Manufacturing” == | |||

There is real overlap—but also fundamental differences. | There is real overlap—but also fundamental differences. | ||

Both reject Fordist rigidity:| Principle | === Where They Converge === | ||

|- | Both reject Fordist rigidity: | ||

| | |||

{| class="wikitable" | |||

| | ! Principle !! Toyota (Lean) !! Flexible Specialization | ||

|- | |||

| High product variety || Yes (mixed-model production) || Yes | |||

large system. | |- | ||

| Rapid changeover || SMED, quick tooling || CNC, modular tooling | |||

|- | |||

| Skilled workers || Problem-solving teams || Craft-like autonomy | |||

|- | |||

| Adaptability || Pull systems, takt || Small-batch reconfiguration | |||

|} | |||

Toyota proved that flexibility does not require small craft firms—it can be engineered into a large system. | |||

=== Where They Diverge === | |||

==== 1. Organizational Structure ==== | |||

'''Flexible Specialization:''' | |||

* Decentralized production | |||

* Networks of small and mid-sized firms | |||

* Regional clusters | |||

* Market-driven coordination | |||

'''Toyota / Lean:''' | |||

* Highly integrated supply chains | |||

Flexibility through | * Central coordination | ||

* Tight standardization | |||

Flexibility through | * Long-term supplier hierarchy | ||

==== 2. Nature of Flexibility ==== | |||

'''Flexible Specialization:''' | |||

Flexibility through general-purpose machines and skilled artisans adapting case-by-case. | |||

'''Toyota:''' | |||

- | Flexibility through standardized processes, takt, kanban, and engineered flow. | ||

==== 3. Strategic vs Operational Focus ==== | |||

''The Second Industrial Divide'' is macro-economic and institutional. | |||

TPS / Lean is micro-operational and process-centric. | |||

== 4. Is ''The Second Industrial Divide'' a Seminal Book in Lean? == | |||

'''Short answer:''' No—but it is seminal in industrial theory and advanced manufacturing strategy. | |||

It does not articulate: | |||

* Value streams | |||

* Flow vs batch | |||

* Pull systems | |||

* Waste categories | |||

* A3 problem solving | |||

* Kaizen culture | |||

Lean is a | Lean is a production philosophy and management system. | ||

''The Second Industrial Divide'' is a theory of industrial organization and political economy. | |||

== 5. Why It Is Still Important == | |||

For | |||

hardware, distributed manufacturing, swarm collaboration | For civilization-level production architectures, open hardware, distributed manufacturing, and swarm collaboration, ''The Second Industrial Divide'' is highly relevant because it: | ||

highly relevant because it: | # Legitimizes non-mass-production futures | ||

# Anticipates distributed, networked manufacturing | |||

# Frames manufacturing as an institutional design problem | |||

== 6. Bottom Line == | |||

* '''Toyota Production System = the operational foundation of lean.''' | |||

* '''The Second Industrial Divide = a foundational theory of flexible, post-Fordist industrial organization.''' | |||

* It is not a lean book, but it is one of the most important intellectual antecedents for distributed manufacturing and modular production systems. | |||

If your aim is operational excellence, Toyota/lean texts are primary. | |||

If your aim is civilizational manufacturing architectures, ''The Second Industrial Divide'' is core reading. | |||

= Additional Integrations: Civilizational Manufacturing Architectures = | |||

- | If we take your framing seriously—'''OSE = Lean (Toyota) + Flexible Specialization (''The Second Industrial Divide'')'''—then you are designing a civilizational manufacturing architecture. | ||

== Key Traditions OSE Builds Upon == | |||

* '''Carlota Perez – ''Technological Revolutions and Financial Capital''''' | |||

* '''Lewis Mumford – ''Technics and Civilization''''' | |||

* '''Yochai Benkler – ''The Wealth of Networks''''' | |||

* '''Jeremy Rifkin – ''The Zero Marginal Cost Society''''' | |||

* '''Stafford Beer – Cybernetics''' | |||

OSE uniquely operationalizes these in physical, open-source infrastructure. | |||

= Biophysical and Ecological Foundations = | |||

== Odum: Energy as the First Accounting System == | |||

* Energy hierarchy governs all systems | |||

* Emergy and the Maximum Power Principle | |||

== Industrial Ecology == | |||

Manufacturing as a material-energy metabolism. | |||

== Ecological Economics == | |||

Daly, Georgescu-Roegen: economy embedded in the biosphere. | |||

- | == Regenerative Design, Permaculture, Panarchy, Gaia Theory == | ||

Civilization as a living, adaptive system. | |||

= Civilization Engineering and the Fermi Paradox = | |||

== Historical and Systems Thinkers == | |||

* Yuval Noah Harari – institutional evolution | |||

* Jared Diamond – ecological constraints and collapse | |||

Industrial | * Joseph Tainter – diminishing returns on complexity | ||

* Vaclav Smil – energy regimes | |||

* Karl Polanyi – political economy | |||

* Jacques Ellul – technological autonomy | |||

* Buckminster Fuller – comprehensive design science | |||

* Donella Meadows – leverage points | |||

* Arnold Toynbee & Oswald Spengler – civilizational life cycles | |||

== Final Synthesis == | |||

** | '''A planetary-scale civilization engineering project designed to test whether intelligent species can redesign their production systems to become ecologically coherent, energetically positive, ethically governed, and institutionally adaptive—before self-termination.''' | ||

* | |||

Latest revision as of 23:32, 11 January 2026

Introduction

OSE is creating economies and civilizations based on integrated systems design. This falls within the field of Complex Systems Theory, and turns the field into practice.

Take a look at a table of existing industry standards in the field - [1]:

Curriculum Development

Interesting discussion starts with Lean, goes into the Toyota Production System, and culminates with the Fermi Paradox.

Discussion

Source - [2]

PDF - File:From Lean to Fermi Paradox.pdf

Reading List - Civilization Systems Engineering

This reading list is designed as a foundation course in Civilization Systems Engineering. It starts with Lean and the Toyota Production System (how to build efficiently), expands to systems engineering and complex systems design (how to architect integrated systems), then moves into civilization history, political economy, ecology/energy constraints, and finally civilization longevity questions (including Fermi-paradox-relevant considerations) and open/distributed production models.

Section 1 — Foundations of Efficient Production and Industrial Systems

These works establish the fundamentals of industrial process design and efficiency — a prerequisite for understanding civilization-scale production systems.

- Toyota Production System: Beyond Large-Scale Production — Taiichi Ohno

- Out of the Crisis — W. Edwards Deming

- The Machine That Changed the World — James P. Womack, Daniel T. Jones, Daniel Roos

- A Study of the Toyota Production System — Shigeo Shingo

Section 2 — Systems Engineering and Complex Systems Design

These texts bridge manufacturing practice to systems-level engineering — essential for making integrated civilization artifacts.

- Systems Engineering Principles and Practice — Alexander Kossiakoff, William Sweet

- The Engineering Design of Systems: Models and Methods — Dennis M. Buede

- The Art of Systems Architecting — Mark W. Maier

- Business Dynamics — John D. Sterman

Section 3 — Foundations of Civilization Theory and Technological History

These interpret how technology, production, and organization shape civilizations.

- Technics and Civilization — Lewis Mumford

- The Myth of the Machine — Lewis Mumford

- Guns, Germs, and Steel — Jared Diamond

- Sapiens: A Brief History of Humankind — Yuval Noah Harari

Section 4 — Political Economy, Institutions, and Societal Structures

To engineer civilization systems, one must understand economic and political constraints.

- The Great Transformation — Karl Polanyi

- Institutions, Institutional Change, and Economic Performance — Douglass North

- Seeing Like a State — James C. Scott

- Governing the Commons — Elinor Ostrom

Section 5 — Ecological and Biophysical Constraints

Civilizations are bounded by energy and ecological constraints; these texts make those limits explicit.

- Energy and Civilization — Vaclav Smil

- Steady-State Economics — Herman Daly

- The Collapse of Complex Societies — Joseph Tainter

- Environment, Power, and Society — Howard T. Odum

Section 6 — Civilization Fate and Long-Term Trajectories

These works expand to civilization-scale evolution and potential trajectories, including Fermi-paradox-relevant ideas.

- The Sustainability Solution to the Fermi Paradox — Jacob Haqq-Misra, Seth Baum

- Normal Accidents: Living with High-Risk Technologies — Charles Perrow

- Manifold (series) — Stephen Baxter

- Engines of Creation — K. Eric Drexler

Section 7 — Open, Distributed Production and Future Civilizations

For a forward look at how open production and networked civilization models might work.

- The Wealth of Networks — Yochai Benkler

- Fab: The Coming Revolution on Your Desktop — Neil Gershenfeld

- The Zero Marginal Cost Society — Jeremy Rifkin

- Operating Manual for Spaceship Earth — R. Buckminster Fuller

Next Steps (Planned)

- Synthesize into a foundation course narrative: why each book matters, and how the ideas build on one another.

- Convert the list into modules with learning objectives, discussion prompts, and OSE-specific application exercises.

- Explicitly connect the lineage to OSE’s understanding of designing “product ecologies and civilization architectures” that enable abundance and broad participation.

Trasnscript

Is there a book better than Eric Ries' The Lean Startup on the topic of lean?

Yes — if your goal is to go beyond the high-level entrepreneurial framing of The Lean Startup and dive deeper into lean principles, history, culture, and practice, there are several books widely regarded as more substantive, foundational, or practical on lean thinking and implementation.

Below are top recommended books depending on what aspect of “lean” you want to master:

1. Classic and Foundational Lean Thinking (Manufacturing & Management)

These books pre-date and in many ways underpin the Lean Startup approach — showing where the principles originally came from and how they scale to organizations.

Lean Thinking: Banish Waste and Create Wealth in Your Corporation

- Authors: James P. Womack & Daniel T. Jones

- Why it’s better (for lean principles): This is one of the most influential books on lean outside of Toyota, articulating the core lean principles like value definition, value stream mapping, flow, pull, and pursuit of perfection.

- This book is broader and more prescriptive on enterprise-wide lean application than Ries’ startup focus.

The Toyota Way: 14 Management Principles from the World’s Greatest Manufacturer

- Author: Jeffrey K. Liker

- Explains Toyota’s management philosophy and culture, including kaizen, respect for people, long-term thinking, and continuous improvement.

- Great if you want to understand why lean works beyond tools and metrics.

The Machine That Changed the World

- Authors: James P. Womack, Daniel T. Jones, and Daniel Roos

- A classic research-based history of Toyota’s development of lean production and its differentiation from craft and mass production systems.

- It’s widely considered the definitive origin story of lean for manufacturing leaders.

2. Practical Lean Implementation (Tools & Mindsets)

These focus less on high-level philosophy and more on day-to-day application and learning processes.

Managing to Learn (A3 Thinking)

- Author: John Shook

- Teaches the A3 problem-solving process — a foundational lean management method used by Toyota and lean practitioners globally.

- Excellent if you want hands-on coaching tools and structured problem framing.

Toyota Way Fieldbook

- Authors: Jeffrey K. Liker & David Meier

- A practical companion to The Toyota Way, with tools, case studies, and detailed methods for applying TPS in your organization.

Gemba Kaizen

- Author: Masaaki Imai

- A classic on continuous improvement (kaizen) with actionable guidance from the shop floor up.

- Good for understanding how to root lean in everyday work practices.

3. Complementary Reads to Expand Lean Startup Thinking

If you liked the strategy and organizational focus of Ries’ work, but want complementary perspectives:

Running Lean

- Author: Ash Maurya

- Takes Lean Startup concepts and turns them into a step-by-step execution playbook — more tactical than The Lean Startup.

Lean Analytics

- Authors: Alistair Croll & Benjamin Yoskovitz

- Deep dive into data-driven experimentation and metrics — helpful if your work emphasizes measuring learning outcomes.

The Startup Owner’s Manual

- Authors: Steve Blank & Bob Dorf

- Not strictly “lean” but offers comprehensive customer development and business model validation frameworks aligned with lean thinking.

Which One Is “Better Than The Lean Startup”?

For lean as a discipline (not just startup methodology):

- Lean Thinking and The Toyota Way are often considered more fundamental than The Lean Startup.

For practical implementation:

- Managing to Learn or Toyota Way Fieldbook provide tools you can use today.

For startup execution beyond theory:

- Running Lean and Lean Analytics will give you hands-on methods and measures that some readers find more actionable than Ries’ narrative.

Recommended Reading Path (Progressive)

- Lean Thinking (foundation in lean principles)

- The Toyota Way (culture + management)

- Managing to Learn / Toyota Way Fieldbook (tools + practice)

- Running Lean / Lean Analytics (startup execution focus)

This sequence takes you from foundational philosophy → cultural understanding → practical tools → startup execution.

If you tell me whether you care most about startup execution, enterprise transformation, or manufacturing operations, I can tailor a reading list with specific short summaries and order.

How does the Toyota method relate to flexible manufacturing discussed in The Second Industrial Divide? Is the latter also a seminal book in the field of lean?

Your question goes to the heart of how “lean” emerged historically—and how it differs from (and overlaps with) “flexible manufacturing” as analyzed in The Second Industrial Divide.

Below is a precise framing.

1. What The Second Industrial Divide Is Actually About

Book: The Second Industrial Divide: Possibilities for Prosperity Authors: Michael Piore & Charles Sabel (1984)

The book is not a “lean” manual. It is a political-economic and industrial organization theory that contrasts two paradigms:

A. Mass Production (First Industrial Divide)

- Fordist, large-batch, dedicated machinery

- Vertical integration

- Low variety, high volume

- Hierarchical control

B. Flexible Specialization (Second Industrial Divide)

- Small-batch, high-variety production

- General-purpose machinery (CNC, modular tooling)

- Skilled labor, craft-like problem solving

- Networked firms, regional clusters (e.g., Emilia-Romagna in Italy)

- Rapid reconfiguration of production systems

Piore and Sabel’s core claim: Advanced capitalism does not have to be mass production; it can be flexible, decentralized, and innovation-driven.

2. What the Toyota Production System (TPS) Is About

Toyota’s system—later labeled “lean”—was developed earlier (1950s–1970s) and systematized in:

- The Machine That Changed the World (1990)

- Lean Thinking (1996)

- The Toyota Way (2004)

Its defining characteristics:

- Just-in-Time: flow, pull, takt

- Jidoka: built-in quality, stop-the-line

- Kaizen: continuous improvement

- Standardized work + respect for people

- Relentless waste elimination (muda)

TPS is not primarily about craft production or decentralization; it is about systematic operational excellence at scale.

3. How TPS Relates to “Flexible Manufacturing”

There is real overlap—but also fundamental differences.

Where They Converge

Both reject Fordist rigidity:

| Principle | Toyota (Lean) | Flexible Specialization |

|---|---|---|

| High product variety | Yes (mixed-model production) | Yes |

| Rapid changeover | SMED, quick tooling | CNC, modular tooling |

| Skilled workers | Problem-solving teams | Craft-like autonomy |

| Adaptability | Pull systems, takt | Small-batch reconfiguration |

Toyota proved that flexibility does not require small craft firms—it can be engineered into a large system.

Where They Diverge

1. Organizational Structure

Flexible Specialization:

- Decentralized production

- Networks of small and mid-sized firms

- Regional clusters

- Market-driven coordination

Toyota / Lean:

- Highly integrated supply chains

- Central coordination

- Tight standardization

- Long-term supplier hierarchy

2. Nature of Flexibility

Flexible Specialization: Flexibility through general-purpose machines and skilled artisans adapting case-by-case.

Toyota: Flexibility through standardized processes, takt, kanban, and engineered flow.

3. Strategic vs Operational Focus

The Second Industrial Divide is macro-economic and institutional. TPS / Lean is micro-operational and process-centric.

4. Is The Second Industrial Divide a Seminal Book in Lean?

Short answer: No—but it is seminal in industrial theory and advanced manufacturing strategy.

It does not articulate:

- Value streams

- Flow vs batch

- Pull systems

- Waste categories

- A3 problem solving

- Kaizen culture

Lean is a production philosophy and management system. The Second Industrial Divide is a theory of industrial organization and political economy.

5. Why It Is Still Important

For civilization-level production architectures, open hardware, distributed manufacturing, and swarm collaboration, The Second Industrial Divide is highly relevant because it:

- Legitimizes non-mass-production futures

- Anticipates distributed, networked manufacturing

- Frames manufacturing as an institutional design problem

6. Bottom Line

- Toyota Production System = the operational foundation of lean.

- The Second Industrial Divide = a foundational theory of flexible, post-Fordist industrial organization.

- It is not a lean book, but it is one of the most important intellectual antecedents for distributed manufacturing and modular production systems.

If your aim is operational excellence, Toyota/lean texts are primary. If your aim is civilizational manufacturing architectures, The Second Industrial Divide is core reading.

Additional Integrations: Civilizational Manufacturing Architectures

If we take your framing seriously—OSE = Lean (Toyota) + Flexible Specialization (The Second Industrial Divide)—then you are designing a civilizational manufacturing architecture.

Key Traditions OSE Builds Upon

- Carlota Perez – Technological Revolutions and Financial Capital

- Lewis Mumford – Technics and Civilization

- Yochai Benkler – The Wealth of Networks

- Jeremy Rifkin – The Zero Marginal Cost Society

- Stafford Beer – Cybernetics

OSE uniquely operationalizes these in physical, open-source infrastructure.

Biophysical and Ecological Foundations

Odum: Energy as the First Accounting System

- Energy hierarchy governs all systems

- Emergy and the Maximum Power Principle

Industrial Ecology

Manufacturing as a material-energy metabolism.

Ecological Economics

Daly, Georgescu-Roegen: economy embedded in the biosphere.

Regenerative Design, Permaculture, Panarchy, Gaia Theory

Civilization as a living, adaptive system.

Civilization Engineering and the Fermi Paradox

Historical and Systems Thinkers

- Yuval Noah Harari – institutional evolution

- Jared Diamond – ecological constraints and collapse

- Joseph Tainter – diminishing returns on complexity

- Vaclav Smil – energy regimes

- Karl Polanyi – political economy

- Jacques Ellul – technological autonomy

- Buckminster Fuller – comprehensive design science

- Donella Meadows – leverage points

- Arnold Toynbee & Oswald Spengler – civilizational life cycles

Final Synthesis

A planetary-scale civilization engineering project designed to test whether intelligent species can redesign their production systems to become ecologically coherent, energetically positive, ethically governed, and institutionally adaptive—before self-termination.