Open Source Induction Furnace Project: Difference between revisions

(→Resources and References: iw link format) |

|||

| Line 108: | Line 108: | ||

* [http://www.educypedia.be/electronics/electricityinduction.htm Educypedia: Induction-related Articles] | * [http://www.educypedia.be/electronics/electricityinduction.htm Educypedia: Induction-related Articles] | ||

* [[Appropedia: Induction Heating]] | * [[Appropedia: Induction Heating]] | ||

* [http://webpages.charter.net/dawill/tmoranwms/Elec_IndHeat7.html] Home made induction heater | |||

* [http://www.allaboutcircuits.com/ Allaboutcircuits: Articles on Electricity and Electronics] | * [http://www.allaboutcircuits.com/ Allaboutcircuits: Articles on Electricity and Electronics] | ||

* [http://www.freepatentsonline.com/3798344.html 1974 US Patent 3798344] Channel Type Induction Furnace (Many induction furnace patents are more than 20 years old, and therefore public domain.) | * [http://www.freepatentsonline.com/3798344.html 1974 US Patent 3798344] Channel Type Induction Furnace (Many induction furnace patents are more than 20 years old, and therefore public domain.) | ||

Revision as of 10:27, 20 July 2011

Main > Digital Fabrication > RepLab Tools > Induction furnace

Project management site: http://openpario.mime.oregonstate.edu/projects/osif

Introduction

The Open Source Induction Furnace Project seems to be the most promising way to implement the foundry. This project involves the design of:

- a high-power induction furnace circuit (between 20 and 50 kW), and

- the melting chamber proper.

Well, we could buy a turnkey system perhaps for $5k total used, and run it from the LifeTrac generator. The only disadvantage to this route is that if it breaks we’re dead-in-the-water – either with the impossibility of fixing closed-source technology, or a high repair bill. A single component which blows and is inaccessible for fixing could in principle turn a working power supply into worthless junk. Thus, it is worthwhile to tame this technology by open-sourcing the design.

Goals

To fulfill our foundry goals, The furnace should have the following characteristics:

- Induction furnace or any other technology that can do this within a budget of 20 kW of electric input, with minimal pollution

- Suitable for melting all metals and alloying

- 300 lb per hour steel melting furnace for casting

- 240 v ac, 20 kW power source available

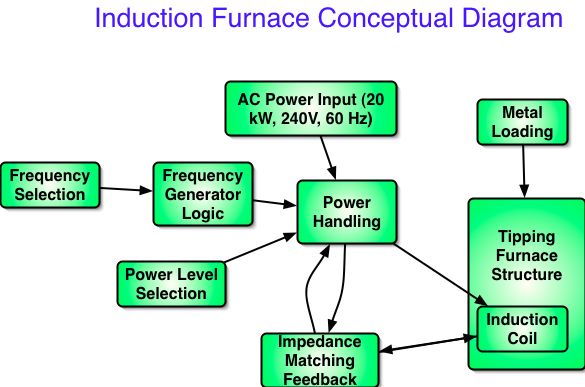

Conceptual Diagram

This is a conceptual diagram of the entire Induction Furnace system from the Global Village Construction Set. The furnace is powered by 20 kW of 240VAC electricity from the LifeTrac generator. The entire system includes the power electronics, induction coil, and heating vessel - into which metal for melting is inserted. This diagram intends to document the relationship of functional components in the induction furnace system, as a basis for technical development of components and their integration.

The electronics part should be adaptable to different metals and different metal melting coil geometries. Melting coils should also be modular, such that the power electronics can feed different coils. Basic functions include selection of heating frequencies, which are required for melting different metals or metal geometries. There should be a feedback in the electronics, where the amount of power given to the coil should match the quantity/geometry of metal being melted.

Details

The complete design should include all of the following:

Induction Furnace Circuit

- Scalable from 20 up to 50 kW in units of 1 or 5 kW

- Allows for power and frequency selection

- Power source may be either 1 or 3 phase electrical power

Heat Dissipation System

Specifications of a cooling or heat dissipation system.

Coil

- Modular, adaptable design specifications for primary coil windings

Melt Chamber

- Geometical design of melt chamber and basic power transfer calculations

- Should include provisions for loading and pouring

- Given our goals, which is best: a coreless or a channel induction furnace type [1] ?

- channel: useful in the melting of lower melt temperature metals; less turbulence at the surface.

- coreless: stronger stirring

- Pouring: manual pouring methods are more suited to low volume production lines.

Crucible

- See: Crucibles for Induction Melting - Guidelines for Selection and Use: http://www.engineeredceramics.com/crucible.htm

Other Considerations

- Complete bill of materials

- Fabrication files for circuit and other components

- Sourcing information for components

- System design and process flow drawings

Notes

Benny

I just read that you plan to build up an induction furnace. That´s a an interesting and exciting plan.While reading the article some remarks came to my mind.

But before I want to introduce myself:

I am Benny from Germany, Hannover. I am diploma engineer for electrotechnology and working at the university. I am dealing with some induction heating/ melting applications like induction melting of glasses (that is possible!) and induction furnaces for cast iron.

Some remarks from my point of view:

- It is possible to build up a low cost furnace with the mentioned parameters.

- The frequency of 9,6 kHz is much to high. The efficiancy will be so bad, that it will be hardly possible to melt steel or iron. Due to the small penetration depth of about 2 mm with this frequency and this electrical resistance. So it needs a really small diameter of the crucible, and thats not helpful. Also the refractory material will be strained too much, so that a small lifetime is given. This will raise the cost for the operating.

- 50 Hz or 60 Hz is a better solution. And you can save the cost for the hf-converter.

- How much material do you want to cast at one time? The maximum, what i expect to be possible with 50 kW will be about 50 to 60 kg.

- What kind of raw material should be charged? It is important for the starting, because the initial density should not be too small (packing density). And the other question is, what kind of scrap it will be.

There are so many problems known with content of zinc (hot zinc dipped) and other materials. The lifetime of common refractory material is really small. And what is more important the security for the personal is not given without a strong exhaust system, due to the toxic steam. I expect this as a strong cost factor.

Power Supply

- 50 kW for $1600 - [2]

- 20 kw STC 3 phase 120 - 480V, also 1 phase - generator - $692 -[3]

- 50 kw STC 3 phase- $1300 - [4]

- LifeTrac 55 hp can produce 38 kW with this head

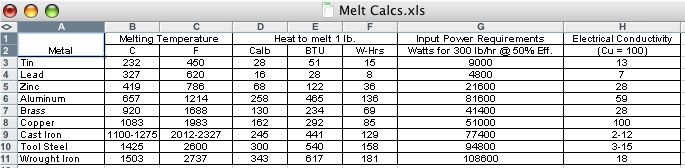

Melt Calculations

Wiki Links

Induction Furnace Request for Bids

External Links

Resources

- Articlesfactory: Furnace Selection

- Inductionheater.org

- Dansworkshop: Induction Heating

- Educypedia: Induction-related Articles

- Appropedia: Induction Heating

- [5] Home made induction heater

- Allaboutcircuits: Articles on Electricity and Electronics

- 1974 US Patent 3798344 Channel Type Induction Furnace (Many induction furnace patents are more than 20 years old, and therefore public domain.)

DIY Furnaces

- http://www.richieburnett.co.uk/indheat.html

- http://www.hvguy.4hv.org/ih/

- http://webpages.charter.net/dawill/tmoranwms/Elec_IndHeat1.html

- Achieved 10 kW; Induction Furnace Kit: http://webpages.charter.net/dawill/tmoranwms/Elec_IndHeat8.html

- http://www.dansworkshop.com/electricity-and-electronics/induction-heating.htm

Commercial

- Commercial induction furnace power supplies from Superior Induction - [6]

- EPRI works with induction - The EPRI Center for Materials Production at Carnegie Mellon, Pittsburgh, PA, 412-268-3243

- List of chinese induction furnace manufacturers

Forum Posts

- You can start your own discussions on our Open Source Induction Furnace Forum

- CNC Zone - Induction furnace topic: http://www.cnczone.com/forums/showthread.php?t=13545

- Metal Casting Zone - Furnace Info: http://www.metalcastingzone.com/metal-casting-forum/casting-furnaces

- Metal and Metallurgy engineering Forum: http://www.eng-tips.com/threadminder.cfm?pid=330&page=1

- Electronics and electricity: http://forum.allaboutcircuits.com/

- Electronics: http://www.electro-tech-online.com/

If you think there are missing or incorrect details here, please help correct that.