Kickstarter: Difference between revisions

No edit summary |

No edit summary |

||

| Line 4: | Line 4: | ||

See the progress to date: | See the progress to date: | ||

'''NEWS: | '''NEWS: We reached our goal on Nov. 3, 2011, and finished up at over $63k gross:''' | ||

[[Image:kickstarter2.jpg]] | [[Image:kickstarter2.jpg]] | ||

Revision as of 23:13, 1 December 2011

We are doing a Global Village Construction Set Kickstarter campaign to assist in the delivery of the OSE Christmas Gift to the World 2011.

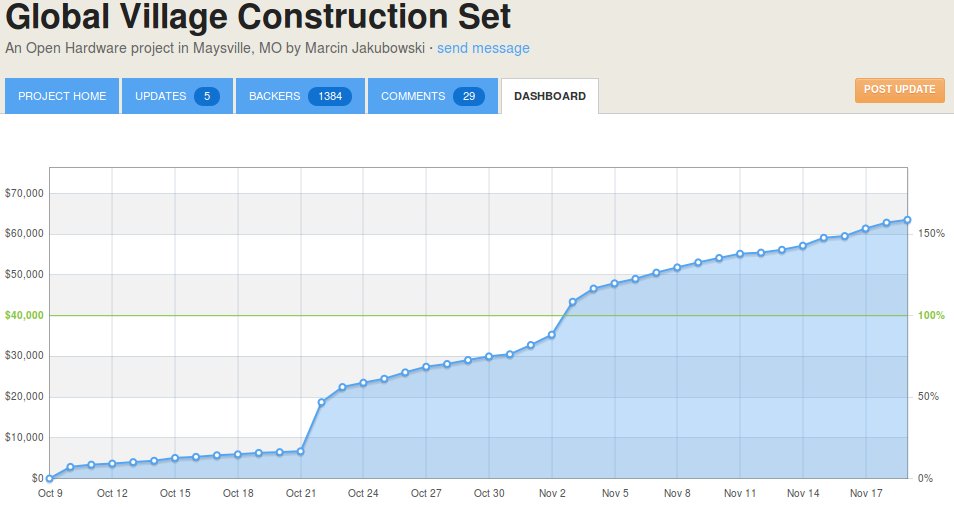

See the progress to date:

NEWS: We reached our goal on Nov. 3, 2011, and finished up at over $63k gross:

Here is our intro video script:

OSE - “THE LAST MILE” KICKSTARTER SCRIPT

Hi, I'm Marcin, founder of Open Source Ecology (caption: Dr. Marcin Jakubowski, PhD) - the network of farmers, engineers, and supporters building the Global Village Construction Set - a low-cost, high performance, open source DIY platform that allows for the easy fabrication of the 50 Industrial Machines that it takes to build a small, sustainable civilization with modern comforts.

So far, we've prototyped 8 of the 50 Machines - the tractor, compressed earth brick press, soil pulverizer, hydraulic power unit, walk-behind tractor, heavy duty drill press, 150 ton hole puncher, and CNC torch table. We've published the designs, instructions, and budgets on our wiki.

This year - we’ve greatly expanded our development team of technical advisors, CAD designers, fabricators, documentors, and wiki editors - and we’ve struck partnerships with existing open hardware projects like lasersaur, solarfire, and Detroit Fab Lab.

Next year, with help from the Kaufmann foundation, we’ll be developing the next 8 prototypes - The Open Source Microfactory - a set of powerful fabrication tools that enable the transformation of scrap metal into products of advanced civilization.

Before we focus on revolutionizing micro-scale fabrication, we’re dedicating our next push to going “the last mile” with the powerful construction toolset we’ve started - The Tractor, Brick Press, Pulverizer, and Power Cube - a highly integrated product ecology that can have enormous impact right now if we can follow through with the crucial, final stages - field testing, data collection, and full documentation - which will make replication a straightforward reality. And we need your help to do this...

To guarantee our most important deliverable - clear, usable instructions, we’ll be dedicating 1/2 of our kickstarter goal exclusively to documentation. We’re promising a published library of instructional materials that will include, for each machine, the design rationale, 3d CAD files, 2d fabrication drawings, exploded part diagrams, CAE analyses, machine-readable CAM files, circuit diagrams, control codes for automated devices, scaling calculations, the physics of why it works, A to Z instructional videos, and the performance and cost analysis comparison to industry standards. We’ll also provide a user manual that includes the operation, safety, maintenance, troubleshooting, and repair.

Before publishing these final results, we’ll need to put these tools through the most rigorous field test to date - the construction of 6 living units and a 3000 square foot fabrication facility here at Factor E Farm. We’ve already achieved the highest brick pressing rates of any open source model (slide: 16 bricks/minute, 5,000 bricks/day), and now we’re aiming to complete the package - by achieving $5 per square foot construction costs, while remaining within industry standard construction schedules. Our goal is to improve dramatically upon the efficiency of natural building - far surpassing the benchmarks of earthbag, cordwood, strawbale, cob, rammed earth, adobe, earthship, and papercrete techniques, while keeping the ecological footprint to bare minimums. We’ll publish a full energy accounting report, including embodied energy estimates for materials and the “joules per day” of both biological (slide: a human being) and electromechanical systems (slide: of the tractor).

As far as we know, this will be a global first - the highest embodied energy efficiencies, the highest construction efficiencies - at the lowest cost, with the least environmental impact. Our aim with This Last Mile is to lower the barriers to creating sustainable human settlements - by providing access to powerful, low-cost, open source tools that anyone can use for transforming their built environment. Help us go “the last mile” to make this happen. Thank you.