Cold Saw/Understand4: Difference between revisions

(→Vise) |

|||

| Line 4: | Line 4: | ||

The vise should be auto-centering such that the vise can accommodate angled cuts more effectively and facilitate the blade descent at the middle of the material width. | The vise should be auto-centering such that the vise can accommodate angled cuts more effectively and facilitate the blade descent at the middle of the material width. | ||

We set the blade slot depth to be deep enough so that the width of the cut is determined by the diameter of the blade and the diameter of the blade supports. | |||

=Diagram= | =Diagram= | ||

Revision as of 19:16, 26 June 2012

Vise

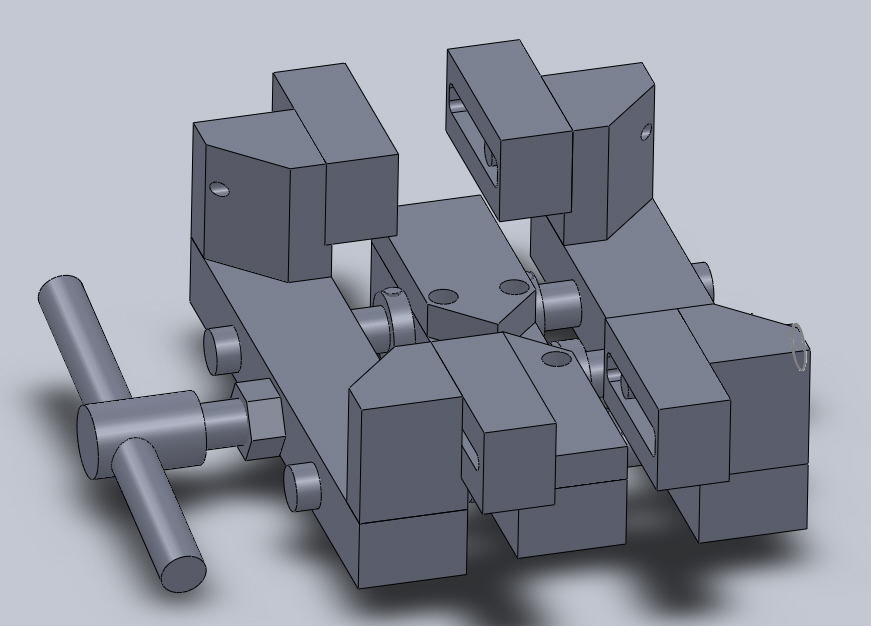

The vise holds the material to be cut.

The vise should be auto-centering such that the vise can accommodate angled cuts more effectively and facilitate the blade descent at the middle of the material width.

We set the blade slot depth to be deep enough so that the width of the cut is determined by the diameter of the blade and the diameter of the blade supports.

Diagram

Calculations

Dimensions

The mounting holes for the vise are 12mm diameter to fit the M12x1.75 screws used uniformly.

The vise shafts are 31.8mm diameter, the same diameter as in the rotation assembly.

The vise threaded rod is M30x3.5 to fit within 32mm diameter holes uniformly used for the vise shafts.

Depth of the blade slot is 25.4mm (20mm required for 350mm diameter blade, 115mm material width, and up to 45 degree cuts)