Information: Difference between revisions

| (51 intermediate revisions by 2 users not shown) | |||

| Line 1: | Line 1: | ||

= | =Language: English= | ||

[[Image: speak.jpg]] | |||

Mathematics | [https://www.youtube.com/embed//36IBDpTRVNE Alphabet] | ||

[https://www.youtube.com/embed//BELlZKpi1Zs Alphabet with Words] | |||

Numbers | |||

Conversational | |||

Colours | |||

Directions | |||

Simple Tenses | |||

Advanced Tenses | |||

Advanced Sentence Structure and Vocabulary | |||

=Mathematics= | |||

What are Numbers | |||

=First Aid and Safety Procedures= | |||

[http://www.realsimple.com/work-life/first-aid-guide-10000001588661/index.html Common First Aid Guide] | |||

[http://www.youtube.com/watch?v=TyYG47xlnvo Hot Work and Explosive Gases] | |||

=Matter= | =Matter= | ||

| Line 19: | Line 45: | ||

Periodic Table of Elements | Periodic Table of Elements | ||

= | =Thermodynamics= | ||

=Electricity= | |||

Electrons have Electric Charge | Electrons have Electric Charge | ||

Voltage ( | [https://www.youtube.com/watch?v=F1p3fgbDnkY Voltage (electrical potential difference) and Current (electron movement)] | ||

[https://www.youtube.com/watch?v=YGvu9iqjJq4 Resistance] | |||

= | [https://www.youtube.com/watch?v=VPxdl1zpcC8 Electromagnetic Induction] | ||

Conductors | Conductors | ||

| Line 34: | Line 62: | ||

[https://www.youtube.com/watch?v=MCe1JXaLEwQ Semiconductor Basics] | [https://www.youtube.com/watch?v=MCe1JXaLEwQ Semiconductor Basics] | ||

Resistors | Resistors | ||

| Line 46: | Line 72: | ||

Integrated Circuits | Integrated Circuits | ||

[https://www.youtube.com/watch?v=gtAaZ2hFYTA&feature=related Wire Conductor Types and Forms] | [https://www.youtube.com/watch?v=gtAaZ2hFYTA&feature=related Wire Conductor Types and Forms] | ||

| Line 59: | Line 83: | ||

[https://www.youtube.com/watch?v=T-5dsaenRig&list=UUlV1gERweBmS9cZduCFiRsQ&index=5&feature=plcp Heat Shrink Tubing Basics] | [https://www.youtube.com/watch?v=T-5dsaenRig&list=UUlV1gERweBmS9cZduCFiRsQ&index=5&feature=plcp Heat Shrink Tubing Basics] | ||

*NiMH: Set power supply at 1.2V with current limit depending on the battery's capacity (ex. if 2500mAh, then set current limit at 2.5A). For multiple batteries, connect the batteries in parallel then set the current limit based on the battery set's capacity (ex. if 30,000mAh, then set current limit at 30A). Lower current limits are ok, but they will result in slower charge rates; higher current limits are situationally ok- if excessive current is channeled for too long a time, then the battery will overheat. | |||

General Guide | [http://www.ibselectronics.com/pdf/pa/walsin/smt_notes.pdf Surface Mount Assembly General Guide] | ||

http://www. | [http://www.onsemi.com/pub_link/Collateral/SOLDERRM-D.PDF Footprint Focused Surface Mounting] | ||

[http://www.google.com/url?sa=t&rct=j&q=&esrc=s&source=web&cd=1&ved=0CGIQFjAA&url=http%3A%2F%2Fdigital.ni.com%2Fpublic.nsf%2Fad0f282819902a1986256f79005462b1%2F7438e77138bddf1b86256f660008e9cc%2F%24FILE%2Flinear_versus_switching.pdf&ei=I1kjUKSFA-e9ywGZxICABw&usg=AFQjCNFjGASY-gy196KbKJ00UaAkiFV02A Linear vs Switched Mode Power Supply] | |||

[https://www.youtube.com/watch?v=5wRcj89U0Pc&list=PL1BFA1481F31F2E3F&index=6&feature=plpp_video&mkt_tok=3RkMMJWWfF9wsRolvqnNZKXonjHpfsX77e0uXqOwlMI%2F0ER3fOvrPUfGjI4ATsJkI%2FqLAzICFpZo2FFLE%2ByUfpM%3D Isolator 101] | |||

[https://www.youtube.com/watch?v=lW-Rstu-aWs&feature=BFa&list=PL1BFA1481F31F2E3F&mkt_tok=3RkMMJWWfF9wsRolvqnNZKXonjHpfsX77e0uXqOwlMI%2F0ER3fOvrPUfGjI4ATsJkI%2FqLAzICFpZo2FFLE%2ByUfpM%3D Selecting an Isolator] | |||

[https://www.youtube.com/watch?v=4enZfma0HVo&feature=BFa&list=PL1BFA1481F31F2E3F&mkt_tok=3RkMMJWWfF9wsRolvqnNZKXonjHpfsX77e0uXqOwlMI%2F0ER3fOvrPUfGjI4ATsJkI%2FqLAzICFpZo2FFLE%2ByUfpM%3D Qualifying an Isolator] | |||

[https://www.youtube.com/watch?v=kduK-ARoXe0&feature=BFa&list=PL1BFA1481F31F2E3F&mkt_tok=3RkMMJWWfF9wsRolvqnNZKXonjHpfsX77e0uXqOwlMI%2F0ER3fOvrPUfGjI4ATsJkI%2FqLAzICFpZo2FFLE%2ByUfpM%3D Isolator Tech Comparisons] | |||

=CNC= | |||

[http://www.5bears.com/cnc01.htm CNC Mill Technical Story] | |||

=Mechanics= | |||

[http://www.ajaxfast.com.au/downloads/Technical%20notehowmanythreads.pdf Thread Analysis] | |||

[http://littlemachineshop.com/Reference/TapDrillSizes.pdf Metric/Imperial Tap Drill Sizes] | |||

Do not use paint on friction mount applications (ex. bolts and nuts) | |||

When using sprocket and chain, ensure at least 180 degrees wrap around each sprocket. | |||

Keep in mind that sprocket chains stretch 5% | |||

Tap 1 layer not both out of 2 layers to be fastened | |||

Use big red emergency buttons | |||

Have designated failure points | |||

Have lubrication mechanisms | |||

=Hydraulics= | |||

[http://www.engineeringtoolbox.com/pvc-cpvc-pipes-dimensions-d_795.html PVC/CPVC Schedule Sizing Chart] | |||

[http://www.colder.com/Portals/0/Library/Resources/Literature/WhitePapers/Documents/Hose-barb-WhitePaper.pdf Hose Barbs] | |||

=Bacteria= | |||

[http://www.romwell.com/cookbook/guide/what_bacteria_need_to_grow.html Bacteria Growth Factors] | |||

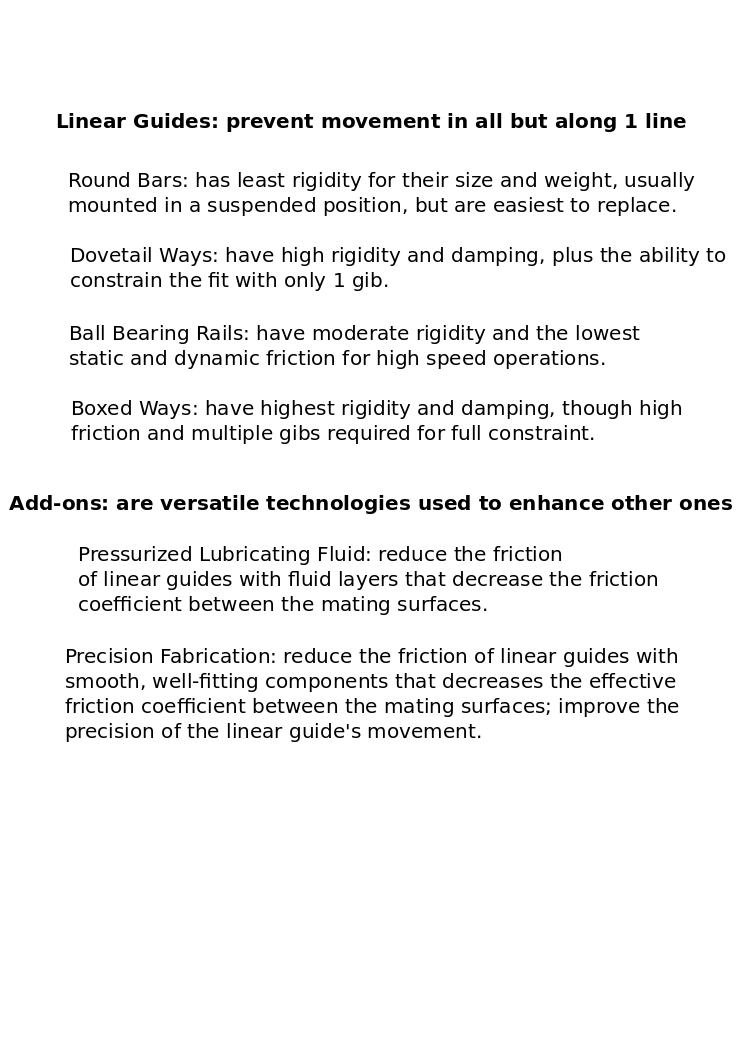

=Linear Guides= | |||

[[Image: linearguides.png]] | |||

=Box Ways vs Linear Ways= | |||

I have a friend who is the sole owner of a shop with 80+ highly modern CNC machines. In one area there are 5 or6 Haas VMC's. They're the only linear way machines in his shop, and they run nothing but aluminum. He specifically forbids the use of these machines for any other purpose, even if there's a backlog of steel parts and the linear way machines are idle. He says his experience has shown two choices for long term use of linear machines on tougher material. Either spend twice the cost per part on tooling that will protect the machine, or use more traditional tooling with the knowledge that you're significantly shortening the life of the machine. They did try the first approach on some parts for a few months around 5 years ago, and he said the numbers just proved his suspicion that the tooling cost would be excessive. On the other hand, the lesser cost of the Haas machines allows him to be more competitive on the aluminum parts than he would be if running the same parts on his high end box way mills. He told me one time one of the keys to making money is to always use a machine thats matched to the job, and not one that just happens to be cheaper or one that would be overkill and too expensive. Starting from his garage about 25 years ago doing work after he got home from his real job, he's in a 100,000 sq ft + shop today and debt free. When he talks about how to make money in the machining business, I always listen closely. | |||

=Dovetails= | |||

Dovetails are what they are. The different angles reflect different approaches to the problem of captivating linear bearing elements and obtaining the required function within a minimum number of machined surfaces. | |||

Another consideration is also minimizing the "stack height" of two or more free moving linear bearings that incorporate mechanical strength and stiff operation while providing space for axis drive elements like lead screws, rack and pinion, and the necessary gearing and linkage. | |||

Anyone who has peered in the guts of a later model Kearney and Trecker mill saddle will see a dazzling example of compact design. | |||

As for the "best" angle, apparently anything from 45 to 60 degrees works. We have over a century of experience with all kinds of fancy angles derived from this proposition or that theory. They all work showing us that design, execution, and materials is probably more important to a stiff, strong, durable dovetail slide than some special dovetail angle. | |||

Loads cantilevered off dovetail bearings in the pitch direction tend to spread them. 60 degree dovetails reflect more spreading force to the flanks than a shallower angle. Most DT slides are fully enveloped these days except for knee mills where the Lamb effect lurks to pounce on the man who tries to turn a turret mill into a jig borer. | |||

At one time or another I've made a couple of dozen dovetail slides from scratch usually with a 60 degree dovetail angle for these reasons only: | |||

On a planer: 1- it's an easier swivel for the planer slides - particularly if tool lift hoses or head interferances are a problem. 2- the inside corner is easier to cut, clean out, and relieve for hand scraping. 3 the clapper box angle isn't so tricky. | |||

On a mill: 1- the necessary cutters are stocked in the toolroom. 2- I don't have to swivel any heads. | |||

In practice: 60 degree dovetails are easier to clean and maintain the wipers than smaller angles. | |||

So mostly it's minimizing time and materials. | |||

=Materials= | |||

[http://www.artsautomotive.com/publications/8-automotive/86-welding-beginner-guide-to-aluminum Aluminum Welding Tips] | |||

=Cutting= | |||

[http://www.diamondbladeselect.com/knowledge/a-comparison-table-of-different-high-speed-steel-hss-grade-standards/ High Speed Steel Grade Standards] | |||

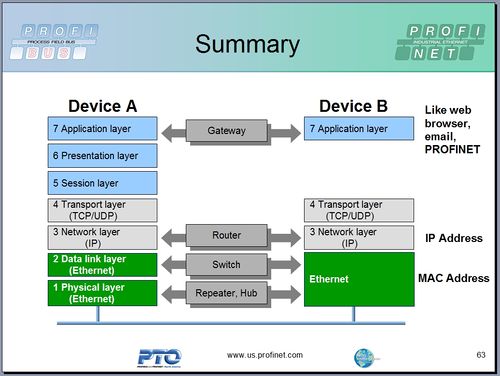

=Telecommunications= | |||

[[File: ISOTelCom.jpg|500px]] | |||

=Documentation= | =Documentation= | ||

[http://opensourceecology.org/wiki/Information | [[Documentation]] | ||

[http://opensourceecology.org/wiki/Technical_Blogging_Standards Technical Blogging Standards and Procedure] | |||

=Open Tech Organizations= | |||

[[Image: techorg.jpg|200px]] | |||

[http://opensourceecology.org/wiki/Open_Organizations Awesome Open Tech Organizations in the Universe!] | |||

=Repositories= | |||

[[Image: repository.jpg|200px]] | |||

[http://opensourceecology.org/wiki/Repositories Databases of Cool Files and Information!] | |||

=Encyclopedia= | =Encyclopedia= | ||

| Line 92: | Line 211: | ||

=News= | =News= | ||

[[News Websites]] | |||

=Documentation Strategy= | =Documentation Strategy= | ||

[[Documentation Strategy]] | |||

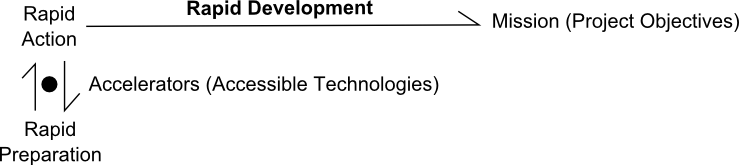

=Development= | |||

[[Image: rapiddevelopment.png]] | |||

---- | |||

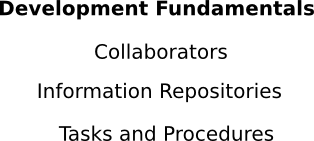

[[Image: devchecks.png]] | |||

---- | |||

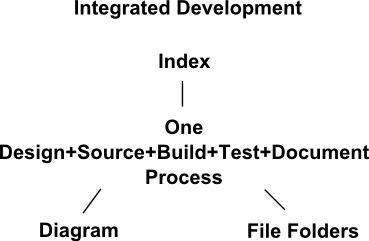

[[Image: integdev.png]] | |||

Latest revision as of 22:15, 15 August 2012

Language: English

Numbers

Conversational

Colours

Directions

Simple Tenses

Advanced Tenses

Advanced Sentence Structure and Vocabulary

Mathematics

What are Numbers

First Aid and Safety Procedures

Matter

Matter is Made of Atoms

Atoms have Protons, Neutrons, and Electrons

Chemistry

Atoms Bond Together

Periodic Table of Elements

Thermodynamics

Electricity

Electrons have Electric Charge

Voltage (electrical potential difference) and Current (electron movement)

Conductors

Insulators

Resistors

Capacitors

Inductors

Transistors

Integrated Circuits

Wire Conductor Types and Forms

- NiMH: Set power supply at 1.2V with current limit depending on the battery's capacity (ex. if 2500mAh, then set current limit at 2.5A). For multiple batteries, connect the batteries in parallel then set the current limit based on the battery set's capacity (ex. if 30,000mAh, then set current limit at 30A). Lower current limits are ok, but they will result in slower charge rates; higher current limits are situationally ok- if excessive current is channeled for too long a time, then the battery will overheat.

Surface Mount Assembly General Guide

Footprint Focused Surface Mounting

Linear vs Switched Mode Power Supply

CNC

Mechanics

Metric/Imperial Tap Drill Sizes

Do not use paint on friction mount applications (ex. bolts and nuts)

When using sprocket and chain, ensure at least 180 degrees wrap around each sprocket.

Keep in mind that sprocket chains stretch 5%

Tap 1 layer not both out of 2 layers to be fastened

Use big red emergency buttons

Have designated failure points

Have lubrication mechanisms

Hydraulics

PVC/CPVC Schedule Sizing Chart

Bacteria

Linear Guides

Box Ways vs Linear Ways

I have a friend who is the sole owner of a shop with 80+ highly modern CNC machines. In one area there are 5 or6 Haas VMC's. They're the only linear way machines in his shop, and they run nothing but aluminum. He specifically forbids the use of these machines for any other purpose, even if there's a backlog of steel parts and the linear way machines are idle. He says his experience has shown two choices for long term use of linear machines on tougher material. Either spend twice the cost per part on tooling that will protect the machine, or use more traditional tooling with the knowledge that you're significantly shortening the life of the machine. They did try the first approach on some parts for a few months around 5 years ago, and he said the numbers just proved his suspicion that the tooling cost would be excessive. On the other hand, the lesser cost of the Haas machines allows him to be more competitive on the aluminum parts than he would be if running the same parts on his high end box way mills. He told me one time one of the keys to making money is to always use a machine thats matched to the job, and not one that just happens to be cheaper or one that would be overkill and too expensive. Starting from his garage about 25 years ago doing work after he got home from his real job, he's in a 100,000 sq ft + shop today and debt free. When he talks about how to make money in the machining business, I always listen closely.

Dovetails

Dovetails are what they are. The different angles reflect different approaches to the problem of captivating linear bearing elements and obtaining the required function within a minimum number of machined surfaces.

Another consideration is also minimizing the "stack height" of two or more free moving linear bearings that incorporate mechanical strength and stiff operation while providing space for axis drive elements like lead screws, rack and pinion, and the necessary gearing and linkage.

Anyone who has peered in the guts of a later model Kearney and Trecker mill saddle will see a dazzling example of compact design.

As for the "best" angle, apparently anything from 45 to 60 degrees works. We have over a century of experience with all kinds of fancy angles derived from this proposition or that theory. They all work showing us that design, execution, and materials is probably more important to a stiff, strong, durable dovetail slide than some special dovetail angle.

Loads cantilevered off dovetail bearings in the pitch direction tend to spread them. 60 degree dovetails reflect more spreading force to the flanks than a shallower angle. Most DT slides are fully enveloped these days except for knee mills where the Lamb effect lurks to pounce on the man who tries to turn a turret mill into a jig borer.

At one time or another I've made a couple of dozen dovetail slides from scratch usually with a 60 degree dovetail angle for these reasons only:

On a planer: 1- it's an easier swivel for the planer slides - particularly if tool lift hoses or head interferances are a problem. 2- the inside corner is easier to cut, clean out, and relieve for hand scraping. 3 the clapper box angle isn't so tricky.

On a mill: 1- the necessary cutters are stocked in the toolroom. 2- I don't have to swivel any heads.

In practice: 60 degree dovetails are easier to clean and maintain the wipers than smaller angles.

So mostly it's minimizing time and materials.

Materials

Cutting

High Speed Steel Grade Standards

Telecommunications

Documentation

Technical Blogging Standards and Procedure

Open Tech Organizations

Awesome Open Tech Organizations in the Universe!

Repositories

Databases of Cool Files and Information!

Encyclopedia

Wikipedia: Free Online Encyclopedia

https://en.wikipedia.org/wiki/Main_Page

Lesson-based Education

Khan Academy

Udacity