Dorkmo Log: Difference between revisions

| Line 10: | Line 10: | ||

[[File:Lathe2.skp]] | [[File:Lathe2.skp]] | ||

[[Image:Lathe5.jpg|400px]] | |||

=Thursday 20, 2013= | =Thursday 20, 2013= | ||

Revision as of 23:27, 21 June 2013

Friday 21, 2013

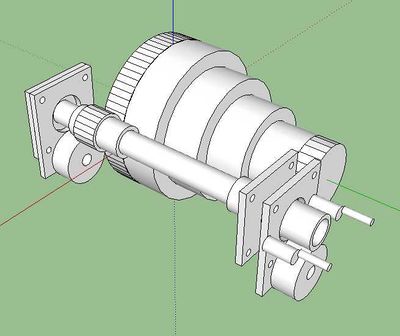

possible motor for lathe surplus center

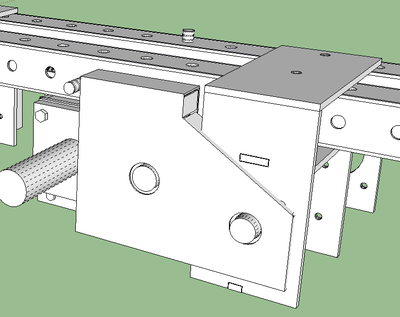

doing a draft with motor mount and threaded rods that tighten to base with some pieces that can c-clamp to base.

Thursday 20, 2013

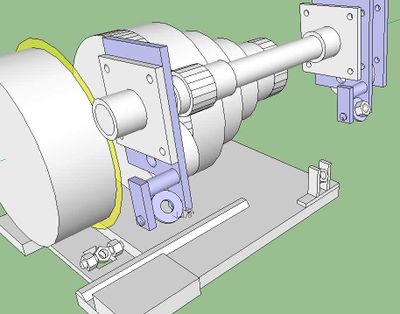

drew a rough sketchup of the lathe. going to redo motor mount. File:Lathe1.skp

found this sprocket openscad thing on thingiverse http://www.thingiverse.com/thing:7918

Tue Jun 18, 2013

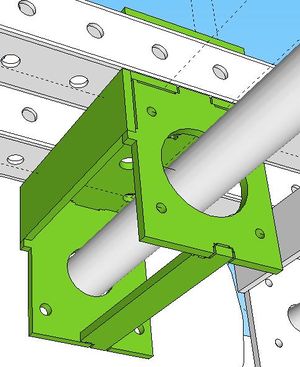

Download DXFs of the 6 parts here - these are 6.26 bolt spacing for these bearings - and DXFs have been corrected for 3/4" bolt holes, meaning 3/4" + 1/16" for CNC torch allowance. File:GeardownDXF.zip

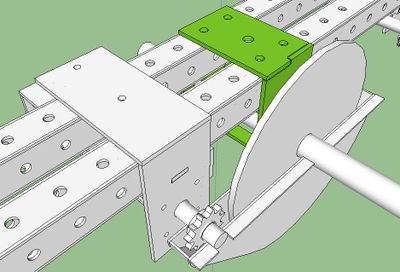

- went back to the basics and cut out intermedate shaft and using a quick attach module style mount.

- requires very large sprocket to achieve desired ratio

- need to change chain cover to accomidate flange bearing bolts sticking through.

DXF Files of Component Plates for Simple Geardown

Sat Jun 15, 2013

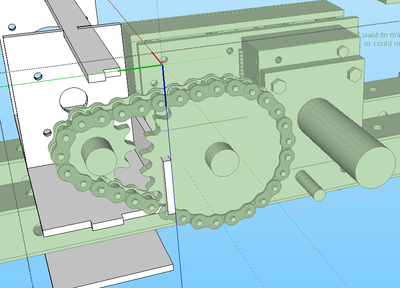

See also Geardown Concept. Download folder of Sketchup files- [1]

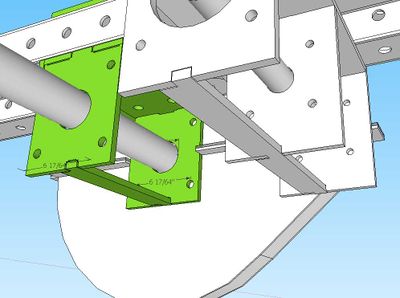

added some detail

- bolts for flange bearings

- had to shift some things around to account for tighter space

- added QD bushing for 1-7/8

- changed a couple mounting bolts to frame

June 8, 2013

Needs discussion of how size can be made more compact.

https://docs.google.com/file/d/0BwxMMqGvwTM-RjJxVGNUVm90aVU/edit?usp=sharing

added to the model a mount style with QA facing opposite direction from before

- shortened distance the 2-15/16 bearing hangs out

cleaned up some of the mounting and case holes

- not sure about where the best places are to have mount holes

June 7, 2013

https://docs.google.com/file/d/0BwxMMqGvwTM-N1piZlVIaGtqUXc/edit?usp=sharing

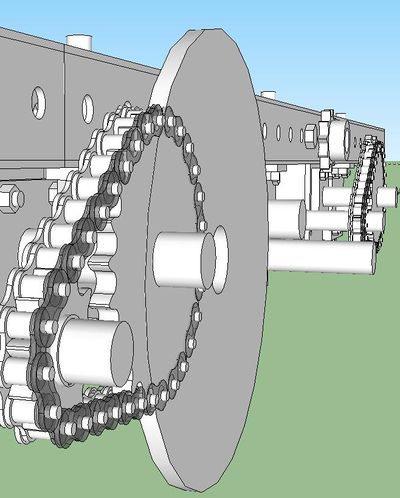

started modeling the chain and sprockets.

- looking for collisions

- taking up as much slack of chain in design as possible

June 1, 2013

Design Sprint - Dozer Geardown