Vegetable Oil Production: Difference between revisions

m (made flow chart larger) |

|||

| (5 intermediate revisions by the same user not shown) | |||

| Line 1: | Line 1: | ||

[[File:Canola Oil and Seeds.jpg|thumb|500px|right|One kilogram of canola seeds — the amount in the plastic bag — makes the amount of oil that’s in this flask. The seeds come from pods like the ones in this dried bouquet.]] | |||

== Overview == | == Overview == | ||

OSE principles suggest minimal use of petroleum products, which often means the substitution of locally produced vegetable oils. Oil crops are also likely to be grown for edible cooking oils. In either case, appropriately-scaled oil processing technology is required. | OSE principles suggest minimal use of petroleum products, which often means the substitution of locally produced vegetable oils. Oil crops are also likely to be grown for edible cooking oils. In either case, appropriately-scaled oil processing technology is required. | ||

| Line 6: | Line 8: | ||

* Cooking oil | * Cooking oil | ||

* [[Hydraulic_Fluid |Hydraulic fluid]] | * [[Hydraulic_Fluid |Hydraulic fluid]] | ||

* Motor fuel ([[Biodiesel]]) | * Motor fuel, as in ([[Biodiesel]]) and [[Pure plant oil as fuel]] | ||

* Lubricating oil (e.g. [http://www.hort.purdue.edu/newcrop/proceedings1999/v4-247.html][http://www.hort.purdue.edu/newcrop/ncnu02/v5-029.html]) | * Lubricating oil (e.g. [http://www.hort.purdue.edu/newcrop/proceedings1999/v4-247.html][http://www.hort.purdue.edu/newcrop/ncnu02/v5-029.html]) | ||

* Paints/coatings | * Paints/coatings | ||

| Line 12: | Line 14: | ||

== Crops == | == Crops == | ||

* Canola (modified rapeseed)[[http://www.hort.purdue.edu/newcrop/nexus/Brassica_rapeseed_nex.html]] | * Canola (modified rapeseed)[[http://www.hort.purdue.edu/newcrop/nexus/Brassica_rapeseed_nex.html]] | ||

* Soybean | * Soybean | ||

* Sunflower[http://www.hort.purdue.edu/newcrop/nexus/Helianthus_annuus_nex.html] | * [[Sunflower]][http://www.hort.purdue.edu/newcrop/nexus/Helianthus_annuus_nex.html] | ||

* Flax (Linseed) | * Flax (Linseed) | ||

== Processes == | == Processes == | ||

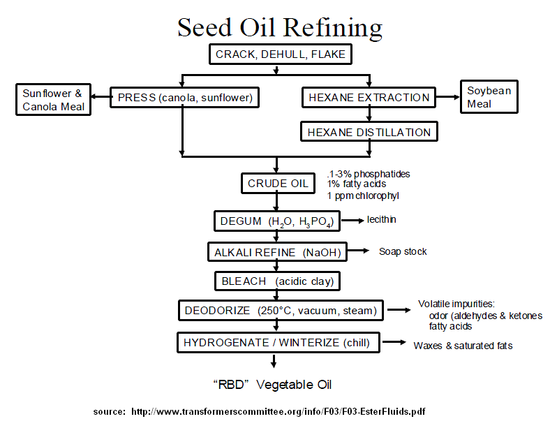

[[File:oilseed_refining.png |thumb]] [[File:Hydraulic_cage_press.png |thumb|An open-frame hydraulic cage press which could be re-implemented with the CEB]] | [[File:oilseed_refining.png|thumb|550px|right]] | ||

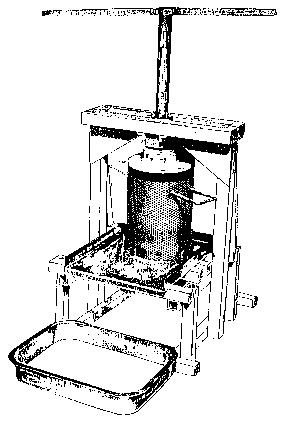

[[File:Hydraulic_cage_press.png |thumb|An open-frame hydraulic cage press which could be re-implemented with the CEB]] | |||

[http://www.cyberlipid.org/oilseed2008.pdf Small scale processing paper] from ATTRA | [http://www.cyberlipid.org/oilseed2008.pdf Small scale processing paper] from ATTRA | ||

| Line 33: | Line 35: | ||

[http://www.aseanfood.info/Articles/11023786.pdf Separating Oil from Aqueous Extraction Fractions of Soybean] examines the use of aqueous (basic) sodium hydroxide solutions for extraction of oil from soybeans processed with different means. A sodium hydroxide mixture is found to be 80-90% efficient but processing to lyse cells is key to a high yield. Lipid droplets are also complexed with lipid binding proteins (oleosin) which can complicate downstream processing. | [http://www.aseanfood.info/Articles/11023786.pdf Separating Oil from Aqueous Extraction Fractions of Soybean] examines the use of aqueous (basic) sodium hydroxide solutions for extraction of oil from soybeans processed with different means. A sodium hydroxide mixture is found to be 80-90% efficient but processing to lyse cells is key to a high yield. Lipid droplets are also complexed with lipid binding proteins (oleosin) which can complicate downstream processing. | ||

[[File:Cage press.png|thumb|500px|left|Bridge press (NRI design).]] | |||

[[Category: Food_and_Agriculture]] | [[Category: Food_and_Agriculture]] | ||

[[Category:Energy]] | |||

[[Category:Biofuel]] | |||

Latest revision as of 00:55, 25 August 2016

Overview

OSE principles suggest minimal use of petroleum products, which often means the substitution of locally produced vegetable oils. Oil crops are also likely to be grown for edible cooking oils. In either case, appropriately-scaled oil processing technology is required.

Applications

- Cooking oil

- Hydraulic fluid

- Motor fuel, as in (Biodiesel) and Pure plant oil as fuel

- Lubricating oil (e.g. [1][2])

- Paints/coatings

- Electrical dielectric fluid [3],(IEEE tutorial)

Crops

Processes

Small scale processing paper from ATTRA

Oilseed pressing on Appropedia

Description of conventional Refined/Bleached/Deodorized(RBD) process in this patent application

The cage press method of expressing oil involves loading seed into a squeezing compartment, applying at least 500psi (higher pressures, up to thousands of psi, improve extraction efficiency) to crush seed and express the liquid oil, then removing the remaining solid oilcake. It seems that with appropriate simple modifications (a perforated pusher block above the moving press foot) the CEB Press could perform this function very effectively.

Separating Oil from Aqueous Extraction Fractions of Soybean examines the use of aqueous (basic) sodium hydroxide solutions for extraction of oil from soybeans processed with different means. A sodium hydroxide mixture is found to be 80-90% efficient but processing to lyse cells is key to a high yield. Lipid droplets are also complexed with lipid binding proteins (oleosin) which can complicate downstream processing.