LifeTrac II Part Sourcing: Difference between revisions

No edit summary |

m (Text replace - "openfarmtech.org/weblog" to "blog.opensourceecology.org") |

||

| (24 intermediate revisions by 3 users not shown) | |||

| Line 1: | Line 1: | ||

[http://blog.opensourceecology.org/2010/09/extreme-traction/ Update] as of Sep. 7, 2010: | |||

<html> | |||

<object width="500" height="310"><param name="allowfullscreen" value="true" /><param name="allowscriptaccess" value="always" /><param name="movie" value="http://vimeo.com/moogaloop.swf?clip_id=14718706&server=vimeo.com&show_title=1&show_byline=1&show_portrait=1&color=&fullscreen=1&autoplay=0&loop=0" /><embed src="http://vimeo.com/moogaloop.swf?clip_id=14718706&server=vimeo.com&show_title=1&show_byline=1&show_portrait=1&color=&fullscreen=1&autoplay=0&loop=0" type="application/x-shockwave-flash" allowfullscreen="true" allowscriptaccess="always" width="500" height="310"></embed></object><p><a href="http://vimeo.com/14718706">Extreme Traction</a> from <a href="http://vimeo.com/user2016419">Marcin Jakubowski</a> on <a href="http://vimeo.com">Vimeo</a>.</p> | |||

</html> | |||

Video of Tractor and Frame assembly in William's second month [[Dedicated Project Visits]] report: | Video of Tractor and Frame assembly in William's second month [[Dedicated Project Visits]] report: | ||

| Line 25: | Line 31: | ||

Rounds: | Rounds: | ||

*<span style="color:green">[4] 22", 27" or 28" × 1-7/8" axle shafts. | *<span style="color:green">[4] 22", 27" or 28" × 1-7/8" axle shafts. | ||

*<span style="color: | *<span style="color:green">[2] 56"×1-7/8" loader shafts. | ||

*<span style="color: | *<span style="color:green">[2] 100"×6"×3" 1/4" or 3/8"? tubes for front loader arms. | ||

*<span style="color: | *<span style="color:green">[2] 86"×6"×3" 1/4" or 3/8"? tubes for rear loader arms. | ||

*<span style="color: | *<span style="color:green">[2] 45"×6"×3" 1/4" or 3/8"? tubes to re-enforce loaders. | ||

*<span style="color: | *<span style="color:green">[8] 6"×4" 3/8" or 1/2" angle-iron to attach re-enforcing tunes to L-arms. | ||

*[44] 5"bolts+nuts + [88] washers to suit to attach re-enforcing tubes, angle-irons & H/cylinders to L-arms. | *[44] 5"bolts+nuts + [88] washers to suit to attach re-enforcing tubes, angle-irons & H/cylinders to L-arms. | ||

*<span style="color: | *<span style="color:green">[4] 4-1/2" 1-7/8" DOM to mount shafts through the frame. | ||

*<span style="color: | *<span style="color:green">[4] 3-1/2" 1-7/8" DOM to mount loader shafts to loader arms. | ||

*<span style="color: | *<span style="color:green">[8] thrust bearings - in the form of large washers with 1-7/8" hole to go between frame-shaft-DOM-mounts and loader arm mounts. | ||

*<span style="color:green">[4] 6" bushings/DOM to weld in gussets and wheel mounts. | *<span style="color:green">[4] 6" bushings/DOM to weld in gussets and wheel mounts. | ||

| Line 39: | Line 45: | ||

*<span style="color:green">[12] 10"×8"×0.5" steel plates to mount flange bearings and hydraulic motors to frame. | *<span style="color:green">[12] 10"×8"×0.5" steel plates to mount flange bearings and hydraulic motors to frame. | ||

*<span style="color: | *<span style="color:green">[4] 6"×8"×1/2" QA-plate to mount motors to QA-motor plate. | ||

*<span style="color: | *<span style="color:green">[2] 12"×12"×1/2" plate to mount H-cylinders to frame base. | ||

*<span style="color: | *<span style="color:green">[4] 12"×4"×1/2" plate to weld to H-cylinder base plates. | ||

*<span style="color:green">[16+] 1"diameter-hole nuts to weld into above plates. | *<span style="color:green">[16+] 1"diameter-hole nuts to weld into above plates. | ||

*<span style="color: | *<span style="color:green">[1] 1/4" 4or5"×36" plate to mount Valves too. | ||

*<span style="color: | *<span style="color:green">[4] 10"×12"×3/8" plate to connect Rear H-cylinders to loader-arms. | ||

*<span style="color: | *<span style="color:green">[4] 8"×12"×3/8" plate to connect Front H-cylinders to loader-arms. | ||

*<span style="color:green">[4] 12×10×1/2" plates to make wheel mounts. | *<span style="color:green">[4] 12×10×1/2" plates to make wheel mounts. | ||

*<span style="color:green">[8] 4"×4"×1/2" plate cut diagonally to make [16] gussets. | *<span style="color:green">[8] 4"×4"×1/2" plate cut diagonally to make [16] gussets. | ||

*[4] × 32"diameter × 9" wheels. | *<span style="color:green">[4] × 32"diameter × 9" wheels. | ||

P.C. & Seat mounting metal: | |||

*<span style="color:green">[1] 144" 4×4" 1/4" thick angle Iron | |||

*<span style="color:green">[1] 88" 2×2" 1/4" angle iron | |||

*<span style="color:green">[1] 192"×4" 3/8" plate | |||

=Other= | =Other= | ||

| Line 60: | Line 72: | ||

*<span style="color:green">[40] 3/4x5-1/2", with [40] washers for one side and [40] metal lock nuts for the other side. For wheel plates & cylinder plates. | *<span style="color:green">[40] 3/4x5-1/2", with [40] washers for one side and [40] metal lock nuts for the other side. For wheel plates & cylinder plates. | ||

*<span style="color:green">[42] 3/4"x9" bolts, [80] washers, and [40] metal lock nuts. This is for the assembly of the main frame. | *<span style="color:green">[42] 3/4"x9" bolts, [80] washers, and [40] metal lock nuts. This is for the assembly of the main frame. | ||

*<span style="color:green">[16] 1/2"x2" bolts + [16] nylon lock nuts + [16] lock washers to suit. Motor attachment to motor interface plate. These could be 2" studs, as these are welded to the motor interface plate. | *<span style="color:green">[16] 1/2"x2" bolts + [16] nylon lock nuts + [16] lock washers to suit. Motor attachment to motor QA/interface plate. These could be 2" studs, as these are welded to the motor QA/interface plate. | ||

*<span style="color:green">[8] 3/4"x2" bolts for motor; [8] nuts to weld; [8] lock washers. Attachment of motor interface plate to frame. | *<span style="color:green">[8] 3/4"x2" bolts for motor; [8] nuts to weld; [8] lock washers. Attachment of motor interface plate to frame. | ||

*<span style="color:green">[32] 5/8"x2"bolts + [32] metal lock nuts, [32] lock washers to suit. Mounting of bearings to frame. | *<span style="color:green">[32] 5/8"x2"bolts + [32] metal lock nuts, [32] lock washers to suit. Mounting of bearings to frame. | ||

| Line 274: | Line 286: | ||

[[Image:lt2splineshaftmale.jpg|thumb|Spline shaft, male]] | [[Image:lt2splineshaftmale.jpg|thumb|Spline shaft, male]] | ||

=Total Weight= | |||

*Frame 4x4x1/4" square tubing - 1277 lb | |||

*Loader arms (2 sets), 3x6x3/8" tubing - 900 lb | |||

*Loader arm shafts, angles - 150 lb (even) | |||

*Loader arm cylinder mount plates (base (66lb) and top(80)) - 146 lb | |||

*Loader arm bottom eyes - 46 | |||

*Hydraulics, wheel bearings - 811 lb | |||

*Wheel mounting plates, gussets, tubes - 112 lb | |||

*Bearing and motor plates - 160 lb | |||

*Wheels - 200 lb | |||

*Wheel tracks (140 lb chain, 209 lb rebar (2.6 lb/ft for 1" rebar)) - 349 lb | |||

*Bolts - 75 lb | |||

*Pins - 30 lb | |||

*Power Cube (1) - 420 lb | |||

*Quick Attach Plates (2 sets) - 234 lb | |||

Total weight of tractor with 2 sets of loader arms, 1 small Power Cube, and wheel tracks 4910 lb dry weight, with 2 Power Cubes - 5330 lb. Weight of loader arms with cylinders and Quick Attach plates: 940 front, 900 back, for total of about 1840 lb. Weight of 2 Power Cube version with only front loader - 4430 lb. | |||

=Cost= | |||

==Basic Structure== | |||

[[Image:LT-frame-BOM.jpg]] | |||

This is about a buck fifty per pound of the 2214 lb machine, or about the going price of tomatoes. That is without the PowerCube. If you use an off-shelf 18 hp engine – the price may be $1225 ($500 for 18 hp engine + $200 pump + $225 frame + $300 balance of system). The total is then $4808. | |||

==Front Loader== | |||

*Heavy duty front loader arm metal (3/8″x3″x6″ rectangular tube) – $500 | |||

*Cylinders – $600 | |||

*Control valve – $200 | |||

*Hoses – $100 | |||

*Couplers and fittings – $100 | |||

*Quick Attach plate – $150Cushion valve – $66 | |||

TOTAL FRONT LOADER COST – $1716 | |||

==Rear Loader== | |||

*Rear Loader Cylinders – $520 | |||

*Heavy duty rear loader arm metal (3/8″x3″x6″ rectangular tube)- $340 | |||

*Selector valve (4) – $180 | |||

*Quick attach plate – $150 | |||

*Cushion valve – $66 | |||

TOTAL REAR LOADER COST – $1256 | |||

==Steel Tracks== | |||

*Chain - 80 feet - $270 at $3.37/foot | |||

*Links - $28 | |||

*Rebar - 140' at $1.57/foot - $220 | |||

TOTAL for Wheel Tracks - $518 | |||

==Quick Attach Plates== | |||

[[Image:qaplates.jpg|thumb|Quick attach plate with levers.]] | |||

(See [http://openpario.mime.oregonstate.edu/projects/oselifetrac/documents Open Pario for design]) | |||

*[6]1"x5" pins (30") - $10 | |||

*[129"] 3/16"x3" sq tubing - $46 | |||

*[113"] 1/2"x3" flat - $34 | |||

*[6"] 1" DOM tubing - $15 | |||

*[24"] 1" rebar - $3 | |||

*[66"] 1/4"x2" flat - $6 | |||

*[6"] 1/2" rebar - $1 | |||

*[15"] 3/4" threaded rod - $3 | |||

*[8] 3/4" lock nuts - $1.60 | |||

*[2] 3/4" nuts - $0.40 | |||

MATERIALS FOR EACH QA PLATE - $124 | |||

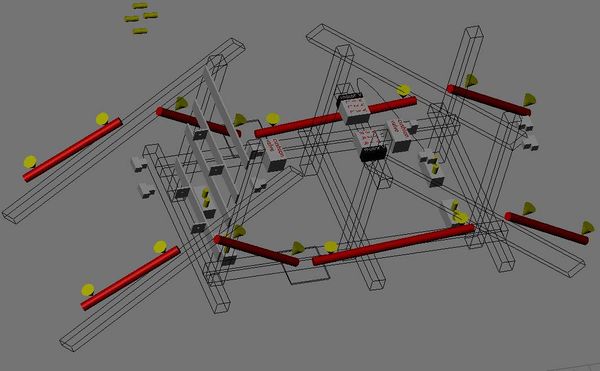

Overall cost for a dual loader tractor – wheel base of about 7×7 feet, designed to handle 3 Power Cubes, for a power limit up to approximately 150 hp – $6550 without the PowerCubes. Design is absolutely scalable, such that a half-size version – or MicroTrac, may be made – and it can be designed readily from our Blender model drawings. | |||

==Package Options== | |||

===Package 1=== | |||

*Basic 4 wheel drive tractor - $3583 | |||

*Tracks - $520 | |||

*Front loader with quick attach plate- $1840 (with quick attach plate) | |||

*Power Cube - $1236 for 18 hp | |||

Total cost is $7179 in materials. The 18 hp may be undersized, so we recommend 2 PowerCubes for 35 hp | |||

===Package 2=== | |||

*Basic 4 wheel drive tractor - $3583 | |||

*Tracks - $520 | |||

*Front loader with quick attach plate- $1840 | |||

*Quick Attach plate - $124 | |||

*Front loader bucket - $400 | |||

*2 Power Cubes - $2472 for 35 hp | |||

Total cost is $8815 in materials fpr 35 hp. | |||

===Package 3=== | |||

Now here’s the good part. We aim to develop the induction furnace within 2 years, with which we will be able to produce all tractor structure and components, minus the rubber parts, from scrap steel. This means that we will demonstrate how to build a tractor at the cost of scrap metal plus rubber, plus energy to run the induction furnace. This should be about $1k in materials such as hoses and hydraulic seals, plus labor. This indicates a possibility of closing the industrial divide between the developed and developing worlds. | |||

[[Category:LifeTrac II]] | [[Category:LifeTrac II]] | ||

Latest revision as of 17:25, 2 July 2013

Update as of Sep. 7, 2010:

Extreme Traction from Marcin Jakubowski on Vimeo.

Video of Tractor and Frame assembly in William's second month Dedicated Project Visits report:

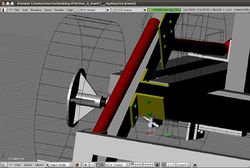

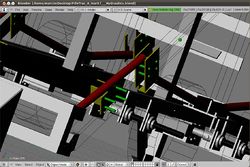

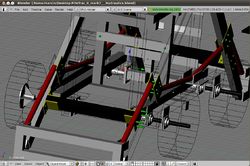

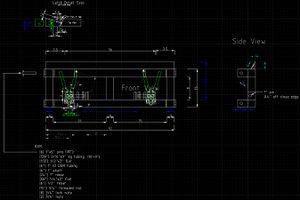

Download open source tractor 3D source code

Cut List

Square tube:

- 4 × 7'8"×4"×4" tubes for base.

- 3 × 5'×4"×4" under base tubes.

- 2 × 52"×4"×4" vertical chassis centre tubes.

- 2 × 55"×4"×4" vertical chassis tubes for front corners.

- 2 × 59"×4"×4" vertical chassis tubes for rear corners (PC mounting area).

- 2 × 84"×4"×4" top chassis tubes.

- 3 × 44"×4"×4" top chassis tubes.

Rounds:

- [4] 22", 27" or 28" × 1-7/8" axle shafts.

- [2] 56"×1-7/8" loader shafts.

- [2] 100"×6"×3" 1/4" or 3/8"? tubes for front loader arms.

- [2] 86"×6"×3" 1/4" or 3/8"? tubes for rear loader arms.

- [2] 45"×6"×3" 1/4" or 3/8"? tubes to re-enforce loaders.

- [8] 6"×4" 3/8" or 1/2" angle-iron to attach re-enforcing tunes to L-arms.

- [44] 5"bolts+nuts + [88] washers to suit to attach re-enforcing tubes, angle-irons & H/cylinders to L-arms.

- [4] 4-1/2" 1-7/8" DOM to mount shafts through the frame.

- [4] 3-1/2" 1-7/8" DOM to mount loader shafts to loader arms.

- [8] thrust bearings - in the form of large washers with 1-7/8" hole to go between frame-shaft-DOM-mounts and loader arm mounts.

- [4] 6" bushings/DOM to weld in gussets and wheel mounts.

Plate:

- [12] 10"×8"×0.5" steel plates to mount flange bearings and hydraulic motors to frame.

- [4] 6"×8"×1/2" QA-plate to mount motors to QA-motor plate.

- [2] 12"×12"×1/2" plate to mount H-cylinders to frame base.

- [4] 12"×4"×1/2" plate to weld to H-cylinder base plates.

- [16+] 1"diameter-hole nuts to weld into above plates.

- [1] 1/4" 4or5"×36" plate to mount Valves too.

- [4] 10"×12"×3/8" plate to connect Rear H-cylinders to loader-arms.

- [4] 8"×12"×3/8" plate to connect Front H-cylinders to loader-arms.

- [4] 12×10×1/2" plates to make wheel mounts.

- [8] 4"×4"×1/2" plate cut diagonally to make [16] gussets.

- [4] × 32"diameter × 9" wheels.

P.C. & Seat mounting metal:

- [1] 144" 4×4" 1/4" thick angle Iron

- [1] 88" 2×2" 1/4" angle iron

- [1] 192"×4" 3/8" plate

Other

- [16] thrust bearings - in the form of large washers with 1-7/8" hole.

Bolts

Functionality list:

- [40] 3/4x5-1/2", with [40] washers for one side and [40] metal lock nuts for the other side. For wheel plates & cylinder plates.

- [42] 3/4"x9" bolts, [80] washers, and [40] metal lock nuts. This is for the assembly of the main frame.

- [16] 1/2"x2" bolts + [16] nylon lock nuts + [16] lock washers to suit. Motor attachment to motor QA/interface plate. These could be 2" studs, as these are welded to the motor QA/interface plate.

- [8] 3/4"x2" bolts for motor; [8] nuts to weld; [8] lock washers. Attachment of motor interface plate to frame.

- [32] 5/8"x2"bolts + [32] metal lock nuts, [32] lock washers to suit. Mounting of bearings to frame.

- [32] 9/16"x2" fine thread bolts, [32] washers, [32] nylon lock nuts. Attachment of wheel to wheel hub. Includes studs, nuts, and washers.

- [4] 3/4"x4.5" bolts; [8] nuts; [4] nylon lock nuts. Mounting of wheel bushings to wheel shafts.

TOTALS:

- [40] 3/4"x5.5" bolts

- [42] 3/4"x9" bolts

- [4] 3/4"x4.5" bolts

- [8] 3/4"x2" bolts

- [120] 3/4" washers

- [80] 3/4" metal lock nuts

- [16] 3/4" nuts

- [4] 3/4" nylon lock nuts

- [8] 3/4" lock washers

- [16] 1/2"x2" bolts

- [16] 1/2" nylon lock nuts

- [16] 1/2" lock washers

- [32] 5/8"x2" bolts

- [32] 5/8" metal lock nuts

- [32] 5/8" lock washers

- [32] 9/16"x2" bolts

- [32] 9/16" washers

- [32] 9/16" nylon lock nuts

Hydraulics

Note that the following list involves 2 loaders. For a simpler version, a single front loader is sufficient. Two loaders are used for extreme flexibility.

(download Blender file here)

(download Blender file here)

Main

Parts from Surplus Center:

Functionality list:

Note: Green indicates finalized shopping list from Surplus Center. Blue indicates list from McMaster Carr. Red is Dalton Hydralics. See Parts Sourcing for contact information.

- [8] 1-7/8" Flange Bearings - [1] or 2-1/2" Flange Bearings [2]

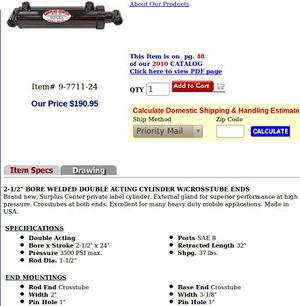

- [2] Front Loader cylinders - 36" - $174 - 48 5/8" retracted length - [3]

- [4] 3/8 NPTM x 1/2 NPTF 90 SWIVEL [4] for Front Loader Cylinders up to hose

- 4.9 square inch area at 2500 PSI implies 12000 lb of force for each cylinder

[0] Rear loader cylinders - [5][0] SAE 8M x 1/2 NPTF 90 SWIVEL [6] for Rear Loader Cylinders- [4] QA plate hydraulic cylinders

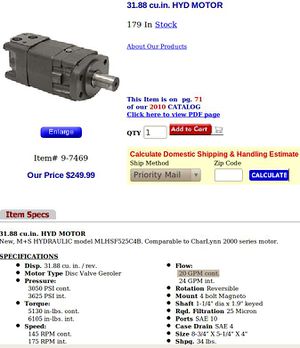

& 2 Rear Loader[7] [0] 3/8 NPTM x 1/2 NPTF 90 SWIVEL [8] for Q.A. Plate Cylinders- [4] Motors - [9]

- [2] 1-1/4 SHAFT COUPLER W 5/16" KEYWAY - [14]

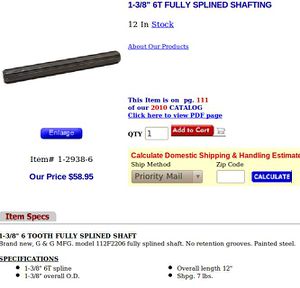

- [2] 1-3/8" 6T fully splined shafting - [15]

- [2] Female 1-3/8" 6T spline coupling - [16], $30 each

- [12] 1.875" double split shaft collars - [17]

- got 10 double split

- got 2 single split - [18]

- [1] 1/2" male QC tip, which already have female part [19]

Valves

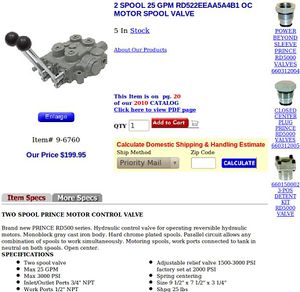

- [1] 3-spool motor valve, 25 gpm - [20], $288

- [4] 1/2" Quick Couplers [21] - for motor valve work ports

- [4] 1/2" NPT M to NPT M 90deg Elbow for Motor Valve working ports [22] - for 2 sets of work ports to wheel motors

- [4] 3/4" NPT quick couplers - Dalton Hydraulics - 2 for in/out, 2 for auxiliary work ports

- [2] 1/2 NPT hex nipples [23]-for auxiliary pair of motor valve work ports

- [2] 3/4 NPT hex nips [24] - in and out of valve

- [2] 3/4 NPT to 1/2 NPT bushing [25] - auxiliary work ports

OSE Danfoss Black 2 Spool

- [4] SAE 8M TO 1/2" NPTM CONNECTOR for working ports [26]

- [6] 1/2" NPT QUICK COUPLER F/F S20-4 [27]

- [1] SAE 10 PLUG for OSE BLACK 2 Spool [28]

- [2] SAE 10M TO 1/2" NPT CONNECTOR [29]

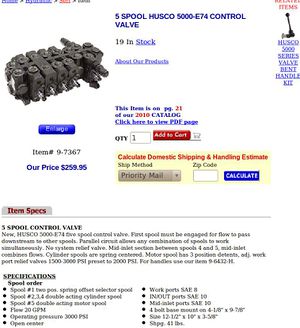

3 Spool Husco

- [1] 3/4" NPT quick couplers - Dalton Hydraulics - 1 pair for inlet

- [1] 3/4" NPT nip - [30] - for inlet

- [3] 1/2" nip for return cross [31]

- [1] 1/2"-1/4" bushing - to accept case drain return [32]

- [2] quick coupler pairs for return line - [33]

- Pipe cross fitting on the return line to accommodate case drain return - [34]

[1] SAE 12 M to NPT 3/4 M Connector [35][1] SAE 10M TO 1/2" NPT CONNECTOR [36][1] 1/2 X 1/2 X 1/2 NPTF TEE [37]

2 Spool Prince Valve

[1] 3/4" Quick Coupler for outlet (already included in central 3-spool motor valve)- [2] 3/4" NPT nip for inlet/outlet - [38]

- [1] 3/4" NPT tee (already have these) for inlet

- [2] 3/4" to 1/2" bushings - [39]

- [1] 1/2" NPT male elbow - [40]

- [2] 1/2" quick coupler pairs - [41]

Cushion Valves

- [2] 1/2 NPT 30 GPM 1500-3000 PSI HYD CUSHION VALVES - [42]

- [4] 1/2" male QC tips to plug into valves, which already have female QCs [43]

- [2] 1/2 NPTM x 1/2 NPTF swivel [44] for cushion valve to mount tees, for separating to right and left cylinders; only one swivel needed per cushion valve

- [4] 1/2" nip - [45] - going from between swivel and tee.

- [4] NPTF Tee [46]- 4 for loaders only, not QA plates

Power Cube

- Note: pump is already obtained

- [1] Coupler half, 5/8" - $10

- [1] Coupler half, 1" - $10

- [1] Solid spider - $14

[1] Breather cap - [47] - $8- [1] 3/4 NPT coupling - found at big box hardware stores

- [1] Suction strainer, 2" to 1-1/4" - [48] - $23

- Use for dual Power Cubes

- [1] Use 2" coupler from bix box store to thread into Power Cube frame

- [1] Pressure relief for power cube bypass- [49]

- [1] 20 GPM return Line Filter - [50]

- [1] 3/4" NPT Swivel for return line filter going into frame - [51]

- [2] 3/4" NPT hex nip on both sides of filter - [52]

- [1] 1"-3/4" NPT reducer bushing for frame receptacle for return filter - [53]

- [1] 3/4" quick coupler for return line to filter

- [2] 1/2" quick couplers for main power lines

Hoses:

- [1] 2 foot hose from pump outlet to return line filter - [54]

- [2] 10 foot hoses, already have these - [55]

Pressure Bypass:

- [1] 1/2" NPT Bypass valve - [56]

- [3] 1/2" Quick couplers - 1 complete for tee near pump, one going from return filter to tee, and male tip for return line. This gives one extra female quick coupler left over. This set of 3 QCs does not cover hoses going from and to the PowerCube.

- [4] 1/2" NPTF hex nip for one and other side of tee, on both tees - [57]

- [2] 1/2" NPTF tee - from outlet of pump to pressure bypass, and from bypass valve into return line filter - [58]

Hoses

Between Motor Valves & Motors

- [4] 1/2" X 36" 1/2 NPTM X 1/2 NPTM 3000 PSI HYD HOSE for in/out of the valves [59]

- [4] 1/2" X 36" 1/2 NPTM X 1/2 NPTM 3000 PSI HYD HOSE for in/out of front motors [60]

- [4] 1/2 X 1/2 X 1/2 NPTF TEE [61]

- [4] 1/2" X 48" 1/2 NPTM X 1/2 NPTM 3000 PSI HYD HOSE for rear motors [62]

Motor Case Drains

- [2] 1/4" X 72" NPTM 2750 PSI HYD HOSE to run parallel with tractor sides [63]

- [1] 1/4" X 30" NPTM 2750 PSI HYD HOSE from Tee to Tee in return hose [64]

- [1] 1/4" X 36" NPTM 2750 PSI HYD HOSE to Rear Motors [65]

- [3] 1/4 X 1/4 X 1/4 NPTF TEE [66]

- [3] 1/4 NPT hex nipples [67]

- [4] 1/4" NPT quick couplers are already with the motors

Front Loader

- [2] 1/2" X 12" 1/2 NPTM X 1/2 NPTM 3000 PSI HYD HOSE from Valves to Cushion [68]

- [2] 1/2" X 36" 1/2 NPTM X 1/2 NPTM 3000 PSI HYD HOSE for left front loader cylinder [69]

- [1] 1/2" X 48" 1/2 NPTM X 1/2 NPTM 3000 PSI HYD HOSE for right front loader cylinder [70]

- [1] 1/2" X 60" 1/2 NPTM X 1/2 NPTM 3000 PSI HYD HOSE for right front loader cylinder [71]

Front loader QA Cylinder Hoses

- [4] 3/8" NPTM x 1/2" NPTF swivel - [72] - swivels for QA cylinders

- [2] 1/2" nips - going from cylinder swivels to tees - [73]

- [2] 1/2" NPTF tees - from cylinder to hoses - [74]

- [2] male QC tips - for plugging into control valves - [75]

- [2] 1/2" X 48" NPTM 3000 PSI HYD HOSE [76]

- [1] 1/2" X 120" NPTM 3000 PSI HYD HOSE [77]

- [1] 1/2" X 144" NPTM 3000 PSI HYD HOSE [78]

Rear Loader Hoses

- [2] 1/2" X 12" 1/2 NPTM X 1/2 NPTM 3000 PSI HYD HOSE to Cushion Valve [79]

- [1] 1/2" X 60" 1/2 NPTM X 1/2 NPTM 3000 PSI HYD HOSE [80]

- [1] 1/2" X 96" 1/2 NPTM X 1/2 NPTM 3000 PSI HYD HOSE [81]

- [1] 1/2" X 84" 1/2 NPTM X 1/2 NPTM 3000 PSI HYD HOSE [82]

- [1] 1/2" X 120" 1/2 NPTM X 1/2 NPTM 3000 PSI HYD HOSE [83]

Rear loader Q.A. Cylinder Hoses

- [4] 3/8" NPTM x 1/2" NPTF swivel - [84] - swivels for QA cylinders

- [2] 1/2" nips - going from cylinder swivels to tees - [85]

- [2] 1/2" NPTF tees - from cylinder to hoses - [86]

- [2] male QC tips - for plugging into control valves - [87]

- [2] 1/2" X 48" NPTM 3000 PSI HYD HOSE [88]

- [1] 1/2" X 120" NPTM 3000 PSI HYD HOSE [89]

- [1] 1/2" X 144" NPTM 3000 PSI HYD HOSE [90]

Seat

- [1] Tractor Seat [91]

|

Total Weight

- Frame 4x4x1/4" square tubing - 1277 lb

- Loader arms (2 sets), 3x6x3/8" tubing - 900 lb

- Loader arm shafts, angles - 150 lb (even)

- Loader arm cylinder mount plates (base (66lb) and top(80)) - 146 lb

- Loader arm bottom eyes - 46

- Hydraulics, wheel bearings - 811 lb

- Wheel mounting plates, gussets, tubes - 112 lb

- Bearing and motor plates - 160 lb

- Wheels - 200 lb

- Wheel tracks (140 lb chain, 209 lb rebar (2.6 lb/ft for 1" rebar)) - 349 lb

- Bolts - 75 lb

- Pins - 30 lb

- Power Cube (1) - 420 lb

- Quick Attach Plates (2 sets) - 234 lb

Total weight of tractor with 2 sets of loader arms, 1 small Power Cube, and wheel tracks 4910 lb dry weight, with 2 Power Cubes - 5330 lb. Weight of loader arms with cylinders and Quick Attach plates: 940 front, 900 back, for total of about 1840 lb. Weight of 2 Power Cube version with only front loader - 4430 lb.

Cost

Basic Structure

This is about a buck fifty per pound of the 2214 lb machine, or about the going price of tomatoes. That is without the PowerCube. If you use an off-shelf 18 hp engine – the price may be $1225 ($500 for 18 hp engine + $200 pump + $225 frame + $300 balance of system). The total is then $4808.

Front Loader

- Heavy duty front loader arm metal (3/8″x3″x6″ rectangular tube) – $500

- Cylinders – $600

- Control valve – $200

- Hoses – $100

- Couplers and fittings – $100

- Quick Attach plate – $150Cushion valve – $66

TOTAL FRONT LOADER COST – $1716

Rear Loader

- Rear Loader Cylinders – $520

- Heavy duty rear loader arm metal (3/8″x3″x6″ rectangular tube)- $340

- Selector valve (4) – $180

- Quick attach plate – $150

- Cushion valve – $66

TOTAL REAR LOADER COST – $1256

Steel Tracks

- Chain - 80 feet - $270 at $3.37/foot

- Links - $28

- Rebar - 140' at $1.57/foot - $220

TOTAL for Wheel Tracks - $518

Quick Attach Plates

(See Open Pario for design)

- [6]1"x5" pins (30") - $10

- [129"] 3/16"x3" sq tubing - $46

- [113"] 1/2"x3" flat - $34

- [6"] 1" DOM tubing - $15

- [24"] 1" rebar - $3

- [66"] 1/4"x2" flat - $6

- [6"] 1/2" rebar - $1

- [15"] 3/4" threaded rod - $3

- [8] 3/4" lock nuts - $1.60

- [2] 3/4" nuts - $0.40

MATERIALS FOR EACH QA PLATE - $124

Overall cost for a dual loader tractor – wheel base of about 7×7 feet, designed to handle 3 Power Cubes, for a power limit up to approximately 150 hp – $6550 without the PowerCubes. Design is absolutely scalable, such that a half-size version – or MicroTrac, may be made – and it can be designed readily from our Blender model drawings.

Package Options

Package 1

- Basic 4 wheel drive tractor - $3583

- Tracks - $520

- Front loader with quick attach plate- $1840 (with quick attach plate)

- Power Cube - $1236 for 18 hp

Total cost is $7179 in materials. The 18 hp may be undersized, so we recommend 2 PowerCubes for 35 hp

Package 2

- Basic 4 wheel drive tractor - $3583

- Tracks - $520

- Front loader with quick attach plate- $1840

- Quick Attach plate - $124

- Front loader bucket - $400

- 2 Power Cubes - $2472 for 35 hp

Total cost is $8815 in materials fpr 35 hp.

Package 3

Now here’s the good part. We aim to develop the induction furnace within 2 years, with which we will be able to produce all tractor structure and components, minus the rubber parts, from scrap steel. This means that we will demonstrate how to build a tractor at the cost of scrap metal plus rubber, plus energy to run the induction furnace. This should be about $1k in materials such as hoses and hydraulic seals, plus labor. This indicates a possibility of closing the industrial divide between the developed and developing worlds.