Solar Power Cube v17.10: Difference between revisions

Tom Griffing (talk | contribs) |

(Added a Category to the Page) |

||

| (46 intermediate revisions by 4 users not shown) | |||

| Line 1: | Line 1: | ||

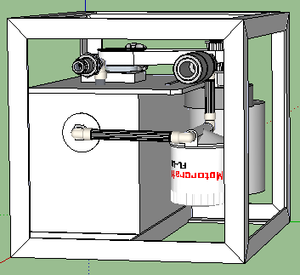

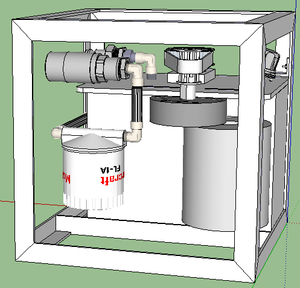

[[image:PC17.10.png|Solar Power Cube 17.10|300px]] | [[image:PC17.10.frontal.png|Solar Power Cube 17.10|300px]] | ||

[[image:PC17.10.profile.png|Solar Power Cube 17.10|300px]] | |||

The solar power cube is driven by a solar panel to pump hydraulic fluid with the initial purpose of powering an autonomous tractor for agricultural use. | The solar power cube is driven by a solar panel to pump hydraulic fluid with the initial purpose of powering an autonomous tractor for agricultural use. | ||

| Line 22: | Line 23: | ||

[http://www.solardesigntool.com/components/module-panel-solar/Hanwha-SolarOne/2921/HSL72P6-PC-1-290/specification-data-sheet.html;jsessionid=7BE62887354D7FE2C0A6800E360BB511 Hanwha Solar Panel] | [http://www.solardesigntool.com/components/module-panel-solar/Hanwha-SolarOne/2921/HSL72P6-PC-1-290/specification-data-sheet.html;jsessionid=7BE62887354D7FE2C0A6800E360BB511 Hanwha Solar Panel] | ||

===DC Motor | ===DC Motor=== | ||

[[Image:PC17.10-450W-DC-Motor-Gear.png 450W DC Motor|200px]] | [[Image:PC17.10-450W-DC-Motor-Gear.png 450W DC Motor|200px]] | ||

| Line 33: | Line 34: | ||

Current Type: DC | Current Type: DC | ||

Gear Ratio: 6.67:1 | Gear Ratio: 6.67:1 | ||

Shaft Diameter: | Shaft Diameter: 19mm (3/4"), threaded 7/16" x 16TPI, screws m4.5 x 15 | ||

Motor Body Diameter: 4 1/4" | |||

Motor Body Length: 5 1/4" | |||

Total Length: 8 1/4" | |||

Total Height: 5.65" | |||

Mount screw spacing: 4" x 2 1/4" | |||

Roller Diameter: 0.3in | |||

Roller Width: 0.16in | |||

Reversible | Reversible | ||

[http://www.ebay.com/itm/450W-36-V-DC-electric-motor-f-bicycle-bike-gokart-scooter-MY1020z-gear-reduction-/162291507158?hash=item25c953dfd6:g:J6YAAOSwiDFYNHRH EBAY MY1020z $67.05] | [http://www.ebay.com/itm/450W-36-V-DC-electric-motor-f-bicycle-bike-gokart-scooter-MY1020z-gear-reduction-/162291507158?hash=item25c953dfd6:g:J6YAAOSwiDFYNHRH EBAY MY1020z $67.05] ( [[Dead Link]] ) | ||

===Hydraulic Power Unit=== | ===Hydraulic Power Unit=== | ||

| Line 76: | Line 67: | ||

[[Image:PC17.10-Timig- | [[Image:PC17.10-Timig-Belt.png|100px]] | ||

===Hydraulic Motor (for reference)=== | ===Hydraulic Motor (for reference)=== | ||

[[Image:PC17.10-Hydr-Motor.png Hydraulic Motor|200px]] | [[Image:PC17.10-Hydr-Motor.png Hydraulic Motor|200px]] | ||

45.6 cubic inch / revolution | |||

Max RPM: 150 | |||

Max fluid flow: 30 GPM | |||

==Calculations== | ==Calculations== | ||

| Line 89: | Line 80: | ||

===Power=== | ===Power=== | ||

Use max solar panel output (290 watts @ 36VDC) to power the motor and calculate motor torque. Then use this torque to calculate the corresponding pump RPM at its rated torque. | |||

The idea is to use the maximum power available from the solar panel to power the motor, then calculate the pulley ratio for delivering the rated torque to the hydraulic pump. The hydraulic flow from the pump will be less than the rated 2GPM, but will deliver the same pressure. | |||

Torque ( | Reference: | ||

Torque (ft-lb) = HP * 33000 / 2 * pi * RPM | |||

HP = Watts / (746 Watts/HP) | |||

HP = Torque * 2 * pi * RPM / 33000 =~ Torque * RPM / 5252 | |||

RPM = HP * 33000 / 2 * pi * Torque (ft-lb) | |||

Rated Solar panel output: | |||

Max Input from solar panel: 290 W or 290W / (746 W/HP) = 0.388 HP | |||

Motor Output: | |||

36V motor efficiency: 78%, so output power is: 0.388 HP * 78% / 100 motor/gearbox efficiency = 0.303 HP | |||

Pump Input: | |||

Torque at rated input (5HP and 3600 RPM): torque = 5 HP * 33000 / 2 * pi * 3600 = 7.29 ft-lb | |||

Solve for pump RPM: RPM = .303 HP * 33000 / 2 * pi * 7.29 ft-lb =~ 218 | |||

Pulley Ratio: | |||

RPM ratios of motor to pump input is: 450:218 (approx 2:1). This should be used to select pulleys for the motor and pump. | |||

===Hydraulic Fluid Flow=== | ===Hydraulic Fluid Flow=== | ||

Use pump specs to calculate displacement: | |||

RPM * CIPR = flow => CIPR = flow / rpm | |||

Pump CIPR = (2 GPM * 231 cu-in/gal) / 3600 = 0.128 | |||

Use displacement to calculate flow when driven by solar panel: | |||

0.128 CIPR * 218 RPM = | |||

PUMP CIPR: 2 GPM @ 3600 RPM = 2 GPM * 231 / 3600 = | |||

GPM from pump at 218 RPM: 0.128 GPM * 218 RPM / 231 cu-in/gal) = 0.12 GPM | |||

===Pulley and Belt Sizing=== | ===Pulley and Belt Sizing=== | ||

The RPM of the electric motor is 450 RPM | The RPM of the electric motor at 36VDC is 450 RPM and must drive the pulley on the hydraulic pump at 218 RPM, so the ratio of pulleys is 450:218 or roughly 2:1. | ||

The smaller pulley must accommodate the motor's 20 mm shaft, so its "OD" must be 20mm + 2 * 5mm to allow 5mm thickness to allow for a set screw. According to PolyBelt.com (http://polybelt.com/5mb.php), the smaller pulley must have at least 20 teeth. | |||

The motor shaft is 13/16" and the shaft on the pump is 1/2". Both pulleys must be machined for their respective shaft sizes and allow enough material for set screws. The smaller pulley requires an OD of about 30mm to allow for machining, making it a 20 tooth pulley. | |||

With motor pulley having 20 teeth, the 2:1 ratio yields 40 teeth for the pump pulley. The larger pulley goes on the pump and the smaller on the electric motor. | |||

Looking up the pulleys on the vendor webpage shows the following part pages: | |||

[http://shop.polybelt.com/36T5-20-2-Aluminum-20-Tooth-Pulley-P36T5-20-2A.htm 20 Tooth Pulley with flanges] | |||

[http://shop.polybelt.com/36T5-40-2-Aluminum-40-Tooth-Pulley-P36T5-40-2.htm 40 Tooth Pulley with flanges] | |||

They don't seem to carry a 20 tooth pulley without the flanges, so we can purchase the bar stock instead, which we can cut and machine to our specs: | |||

[http://shop.polybelt.com/T5-20-Pulley-Bar-Stock-Aluminum-PBT5-20-160A.htm 20 Tooth Pulley Bar Stock] | |||

This will be better for the smaller pulley, as we need more height to make up for the sort motor shaft. | |||

Calculate pulley diameters: | |||

Diameter = Pitch * #teeth / pi | |||

Motor pulley dia: 5mm * 20 / pi = 31.83mm | |||

Pump pulley dia: 5mm * 40 / pi = 63.66mm | |||

The approximate distance between shaft centers is 4.625" (117mm) | |||

The "formal" calculation of belt length with different size pulleys is rather complex, but as our pulleys are close and we have an adjustment, we can use a simple approximation for the belt length (d = 117mm): | |||

pi * (d1 + d2)/2 + 2 * d = pi * (31.83mm + 63.66mm)/2 + 2 * 117mm = 384mm (15.11") | |||

#teeth = 384mm / 5 mm/tooth = 76.8 or about 77 teeth | |||

Looking it up on vendor page, the nearest larger size has 78 teeth (part #B25T5/390FPS): | |||

[http://shop.polybelt.com/25T5-390-Polyurethane-Steel-Timing-Belt-78-Tooth-B25T5-390FPS.htm 25T5/390 Polyurethane Steel Timing Belt 78 Tooth] | |||

==Power Cube Working Document== | ==Power Cube Working Document== | ||

<html><iframe src="https://docs.google.com/spreadsheets/d/1KNVP2O3KogC6jyxMuRALWTxrYjyCJ4ChjeZsJVdqHsg/ | <html><iframe src="https://docs.google.com/spreadsheets/d/1KNVP2O3KogC6jyxMuRALWTxrYjyCJ4ChjeZsJVdqHsg/edit?usp=sharing" height=500 width=500></iframe></html> | ||

["https://docs.google.com/spreadsheets/d/1KNVP2O3KogC6jyxMuRALWTxrYjyCJ4ChjeZsJVdqHsg/edit#gid=1"] | ["https://docs.google.com/spreadsheets/d/1KNVP2O3KogC6jyxMuRALWTxrYjyCJ4ChjeZsJVdqHsg/edit#gid=1"] | ||

=Discussion= | |||

EBay has pulleys, but I don’t see bar stock: | |||

https://www.ebay.com/itm/36T5-40-2-T5-Aluminium-Precision-Timing-Belt-Pulley-25mm-Wide-x-40-Tooth-/201616982777?epid=1089974188&hash=item2ef14f02f9:g:3BMAAOSwzJ5Xen8D | |||

We could keep the pulley ratios and go with 21 tooth bar and 42 tooth pulley - which are both in stock: | |||

http://shop.polybelt.com/T5-21-Pulley-Bar-Stock-Aluminum-PBT5-21-160A.htm | |||

http://shop.polybelt.com/36T5-42-2-Aluminum-42-Tooth-Pulley-P36T5-42-2A.htm | |||

Of course, we would have to re-calculate the belt length: | |||

pi * (d1 + d2)/2 + 2 * d = pi * (32.7mm + 66mm)/2 + 2 * 117mm = 389mm (15.3") | |||

#teeth = 384mm / 5 mm/tooth = 77.8 or about 78 teeth | |||

Strangely, this is the same part number (the previous one was oversized a bit): | |||

http://shop.polybelt.com/25T5-390-Polyurethane-Steel-Timing-Belt-78-Tooth-B25T5-390FPS.htm | |||

==12 Volt Auxilary Power== | |||

*need to convert solr panel's 36V to 12V to use for solenoids and arduino | |||

===Golf Cart Converter=== | |||

*https://www.amazon.com/JahyShow%C2%AE-Voltage-Reducer-Converter-Waterproof/dp/B01H8314J2/ | |||

===Charge Controller=== | |||

==Files== | |||

[[file:Solar_Power_Cube_V1.0.skp]] | |||

[[file:Solar_Power_Cube_V1.0_BOM.pdf]] | |||

[[Category: Dead Links]] [[Category: Power Cube]] | |||

Latest revision as of 22:55, 5 November 2022

The solar power cube is driven by a solar panel to pump hydraulic fluid with the initial purpose of powering an autonomous tractor for agricultural use.

Specifications

Solar Panel

STC Power Rating 290W PTC Power Rating 263.07W 1 STC Power per unit of area 13.8W/ft2 (148.2W/m2) Peak Efficiency 14.82% Power Tolerances -3%/+3% Number of Cells 72 Nominal Voltage not applicable Imp 8.02A Vmp 36.4V Dimensions: 77.6in (1,972mm) x 39.1in (992mm) x 1.6in (40mm) Weight: 50.7lb (23kg) Hanwha Solar Panel

DC Motor

450W 36 V DC electric motor MY1020z gear reduction Input Voltage: 36 V Base RPM: 450 Wires: 12 Gauge Efficiency: 78% Full Load Amps: 16 Current Type: DC Gear Ratio: 6.67:1 Shaft Diameter: 19mm (3/4"), threaded 7/16" x 16TPI, screws m4.5 x 15 Motor Body Diameter: 4 1/4" Motor Body Length: 5 1/4" Total Length: 8 1/4" Total Height: 5.65" Mount screw spacing: 4" x 2 1/4" Roller Diameter: 0.3in Roller Width: 0.16in Reversible EBAY MY1020z $67.05 ( Dead Link )

Hydraulic Power Unit

Power 5 HP 3600 RPM Flow 2 GPM max. Pressure 2500 PSI max. Reservoir 1.1 gallons Shaft 1/2" dia. x 7/8" w/keyway Rotation CW Ports 3/8" NPT pressure Return 3/8" & 3/4" NPT Orientation Vertical Size 10" x 10" x 10" Shpg. 13 lbs. Surplus Center Hydraulic Power Unit $109.95

Timing Belt and Pulleys

Hydraulic Motor (for reference)

45.6 cubic inch / revolution Max RPM: 150 Max fluid flow: 30 GPM

Calculations

Power

Use max solar panel output (290 watts @ 36VDC) to power the motor and calculate motor torque. Then use this torque to calculate the corresponding pump RPM at its rated torque.

The idea is to use the maximum power available from the solar panel to power the motor, then calculate the pulley ratio for delivering the rated torque to the hydraulic pump. The hydraulic flow from the pump will be less than the rated 2GPM, but will deliver the same pressure.

Reference:

Torque (ft-lb) = HP * 33000 / 2 * pi * RPM HP = Watts / (746 Watts/HP) HP = Torque * 2 * pi * RPM / 33000 =~ Torque * RPM / 5252 RPM = HP * 33000 / 2 * pi * Torque (ft-lb)

Rated Solar panel output:

Max Input from solar panel: 290 W or 290W / (746 W/HP) = 0.388 HP

Motor Output:

36V motor efficiency: 78%, so output power is: 0.388 HP * 78% / 100 motor/gearbox efficiency = 0.303 HP

Pump Input:

Torque at rated input (5HP and 3600 RPM): torque = 5 HP * 33000 / 2 * pi * 3600 = 7.29 ft-lb Solve for pump RPM: RPM = .303 HP * 33000 / 2 * pi * 7.29 ft-lb =~ 218

Pulley Ratio:

RPM ratios of motor to pump input is: 450:218 (approx 2:1). This should be used to select pulleys for the motor and pump.

Hydraulic Fluid Flow

Use pump specs to calculate displacement:

RPM * CIPR = flow => CIPR = flow / rpm Pump CIPR = (2 GPM * 231 cu-in/gal) / 3600 = 0.128

Use displacement to calculate flow when driven by solar panel:

0.128 CIPR * 218 RPM =

PUMP CIPR: 2 GPM @ 3600 RPM = 2 GPM * 231 / 3600 = GPM from pump at 218 RPM: 0.128 GPM * 218 RPM / 231 cu-in/gal) = 0.12 GPM

Pulley and Belt Sizing

The RPM of the electric motor at 36VDC is 450 RPM and must drive the pulley on the hydraulic pump at 218 RPM, so the ratio of pulleys is 450:218 or roughly 2:1.

The smaller pulley must accommodate the motor's 20 mm shaft, so its "OD" must be 20mm + 2 * 5mm to allow 5mm thickness to allow for a set screw. According to PolyBelt.com (http://polybelt.com/5mb.php), the smaller pulley must have at least 20 teeth.

The motor shaft is 13/16" and the shaft on the pump is 1/2". Both pulleys must be machined for their respective shaft sizes and allow enough material for set screws. The smaller pulley requires an OD of about 30mm to allow for machining, making it a 20 tooth pulley.

With motor pulley having 20 teeth, the 2:1 ratio yields 40 teeth for the pump pulley. The larger pulley goes on the pump and the smaller on the electric motor.

Looking up the pulleys on the vendor webpage shows the following part pages:

20 Tooth Pulley with flanges 40 Tooth Pulley with flanges

They don't seem to carry a 20 tooth pulley without the flanges, so we can purchase the bar stock instead, which we can cut and machine to our specs:

20 Tooth Pulley Bar Stock

This will be better for the smaller pulley, as we need more height to make up for the sort motor shaft.

Calculate pulley diameters:

Diameter = Pitch * #teeth / pi Motor pulley dia: 5mm * 20 / pi = 31.83mm Pump pulley dia: 5mm * 40 / pi = 63.66mm

The approximate distance between shaft centers is 4.625" (117mm)

The "formal" calculation of belt length with different size pulleys is rather complex, but as our pulleys are close and we have an adjustment, we can use a simple approximation for the belt length (d = 117mm):

pi * (d1 + d2)/2 + 2 * d = pi * (31.83mm + 63.66mm)/2 + 2 * 117mm = 384mm (15.11") #teeth = 384mm / 5 mm/tooth = 76.8 or about 77 teeth

Looking it up on vendor page, the nearest larger size has 78 teeth (part #B25T5/390FPS):

25T5/390 Polyurethane Steel Timing Belt 78 Tooth

Power Cube Working Document

["https://docs.google.com/spreadsheets/d/1KNVP2O3KogC6jyxMuRALWTxrYjyCJ4ChjeZsJVdqHsg/edit#gid=1"]

Discussion

EBay has pulleys, but I don’t see bar stock:

We could keep the pulley ratios and go with 21 tooth bar and 42 tooth pulley - which are both in stock:

http://shop.polybelt.com/T5-21-Pulley-Bar-Stock-Aluminum-PBT5-21-160A.htm http://shop.polybelt.com/36T5-42-2-Aluminum-42-Tooth-Pulley-P36T5-42-2A.htm

Of course, we would have to re-calculate the belt length:

pi * (d1 + d2)/2 + 2 * d = pi * (32.7mm + 66mm)/2 + 2 * 117mm = 389mm (15.3")

#teeth = 384mm / 5 mm/tooth = 77.8 or about 78 teeth

Strangely, this is the same part number (the previous one was oversized a bit): http://shop.polybelt.com/25T5-390-Polyurethane-Steel-Timing-Belt-78-Tooth-B25T5-390FPS.htm

12 Volt Auxilary Power

- need to convert solr panel's 36V to 12V to use for solenoids and arduino

Golf Cart Converter

Charge Controller

Files

File:Solar Power Cube V1.0.skp File:Solar Power Cube V1.0 BOM.pdf