Cut CEB Metal: Difference between revisions

Jump to navigation

Jump to search

(Created page with "Cut 10 pieces of 7/16"x6" heavy u-channel (this link should be filled with (1) a technical drawing from a library of any professional CAD package); (2) a real picture of the ...") |

|||

| (7 intermediate revisions by the same user not shown) | |||

| Line 1: | Line 1: | ||

Cut 10 pieces of [[7/16"x6" heavy u-channel]] (this link should be filled with (1) a technical drawing from a library of any professional CAD package); (2) a real picture of the material, (3) a real picture or video of someone cutting it (all of: abrasive, cold cut, band, plasma, or oxy torch) | =Frame= | ||

*Cut 10 pieces of [[7/16"x6" heavy u-channel]] (this link should be filled with (1) a technical drawing from a library of any professional CAD package); (2) a real picture of the material, (3) a real picture or video of someone cutting it (all of: abrasive, cold cut, band, plasma, or oxy torch) | |||

[[Image:3_cebfab.jpg|200px|Proto 1 - now frame is updated to 3/4" bolts and longer mid pieces.]] | |||

[[Image:3_cebfab.jpg|200px|Beta Release - updated frame.]] | |||

*6 inch heavy (7/16") u-channel - ( 20 ft ) | |||

[[Image:channel.jpg|thumb|Step 1. Torch or cold-cut channel to size]] | |||

Cut the following pieces out of the 6 inch heavy (7/16") u-channel steel: | |||

*A - 2 pieces, 44" | |||

*B - 2 pieces, 29" | |||

*C - 4 pieces, 21" | |||

*D - 2 pieces, 9" | |||

=Cylinder and Mounts= | |||

*3”x3”x1/2” (8) (cylinder mounts for both cylinders) | |||

*1” shaft, 6” long (main cylinder mount) | |||

*5 X 8 3000PSI Welded Cross-Tube Hydraulic Cylinder [http://stores.daltonhydraulic.com/-strse-530/Welded-Cross-dsh-Tube-Prince-Hydraulic/Detail.bok?category=Welded+Cross-Tube+Hydraulic+Cylinders%3A5+Inch+Bore Buy] | |||

===Step 2: Punch holes=== | |||

[[Image:punchedholes.jpg|thumb|Step 2]] | |||

*A - 1" from the tip of the edge, in the edges of 41 1/2" upright pieces at the following locations: 1", 5", 36.5", 40.5"(more to follow) | |||

*B - Four holes in each of the 28 3/4" pieces such that they are 19.4" apart on the long axis and 4"(?not sure) apart on the short axis. They should form a centred rectangle parallel to each of the 26" pieces. | |||

*C - Four holes in each of the 20 3/4" pieces such that they are 19.4" apart on the long axis and 4"(?not sure) apart on the short axis. They should form a centered rectangle parallel to each of the 18" pieces. | |||

*D - | |||

*E - | |||

===Step 3: Bolt pieces together=== | |||

[[Image:Framestanding.jpg|thumb| Step 3]] | |||

===Step 4: Prepare Hydraulic Cylinder=== | |||

== Diagram and video explantion == | |||

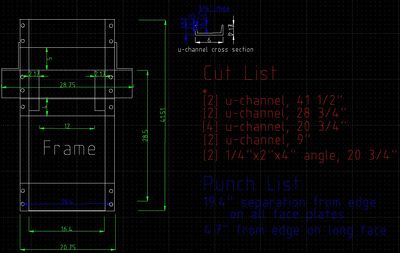

This diagram shows the pieces needed for the frame. Click to enlarge: | |||

[[Image:feflibframe.jpg|400px]] | |||

<html><embed src="http://blip.tv/play/AYHmjQYA" type="application/x-shockwave-flash" width="426" height="340" allowscriptaccess="always" allowfullscreen="true"></embed></html> | |||

*[4] 21" long - top and bottom of frame | *[4] 21" long - top and bottom of frame | ||

| Line 14: | Line 53: | ||

*[2] 1/4"x2" angle, 21" long - hopper closure | *[2] 1/4"x2" angle, 21" long - hopper closure | ||

*[2] 1/4"x2" angle - 7" long - hopper closure tab for cylinder alignment | *[2] 1/4"x2" angle - 7" long - hopper closure tab for cylinder alignment | ||

=Drawer= | |||

* | =Hopper= | ||

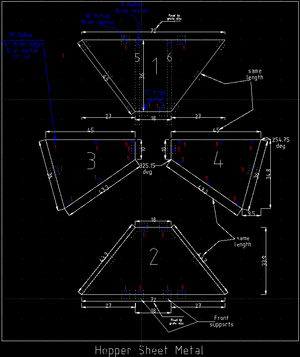

*Plasma cut sheet metal | |||

*Punch 3/4" holes in all 28 hinges, in center of rounded part | |||

*Punch holes in hopper sheet metal (all the blue holes, 3/4") | |||

[[Image:hopperfab.png|thumb]] | |||

*Bolt all hinges to sheet metal at the red locations marked "1" with 3/4" bolts | |||

*Weld bottom hinges of ''hopper sheet 1'' to hopper mount plate | |||

*Weld top hinges of hopper sheet 1 to grate | |||

*Install hopper supports to hold hopper sheet 1, and bolt with the 2 bolts (1/2") | |||

*Weld hinges to hopper supports for sheet 2 | |||

*Weld hinges at base of sheets 2, 3, 4 | |||

*Weld hinges between sheets 3&1, 4&1, and between 2&3, and 2&4 | |||

*At this point, the entire hopper is erected. It remains to weld the remaining hinges to the grate. | |||

*Upon completing these steps, the 3/4" bolts can be replaced with 1/2" bolts for successive deconstruction and reconstruction of the hopper. | |||

=hopper supports= | |||

=shaker= | |||

=hopper interface plate= | |||

*[2] 3/4" pipe, 1" long - cylinder aligner | *[2] 3/4" pipe, 1" long - cylinder aligner | ||

*[2] u-channel, 3" - cylinder align | *[2] u-channel, 3" - cylinder align | ||

[[Category:Fabrication | [[Category:CEB Press Fabrication]] | ||

Latest revision as of 23:10, 3 July 2011

Frame

- Cut 10 pieces of 7/16"x6" heavy u-channel (this link should be filled with (1) a technical drawing from a library of any professional CAD package); (2) a real picture of the material, (3) a real picture or video of someone cutting it (all of: abrasive, cold cut, band, plasma, or oxy torch)

- 6 inch heavy (7/16") u-channel - ( 20 ft )

Cut the following pieces out of the 6 inch heavy (7/16") u-channel steel:

- A - 2 pieces, 44"

- B - 2 pieces, 29"

- C - 4 pieces, 21"

- D - 2 pieces, 9"

Cylinder and Mounts

- 3”x3”x1/2” (8) (cylinder mounts for both cylinders)

- 1” shaft, 6” long (main cylinder mount)

- 5 X 8 3000PSI Welded Cross-Tube Hydraulic Cylinder Buy

Step 2: Punch holes

- A - 1" from the tip of the edge, in the edges of 41 1/2" upright pieces at the following locations: 1", 5", 36.5", 40.5"(more to follow)

- B - Four holes in each of the 28 3/4" pieces such that they are 19.4" apart on the long axis and 4"(?not sure) apart on the short axis. They should form a centred rectangle parallel to each of the 26" pieces.

- C - Four holes in each of the 20 3/4" pieces such that they are 19.4" apart on the long axis and 4"(?not sure) apart on the short axis. They should form a centered rectangle parallel to each of the 18" pieces.

- D -

- E -

Step 3: Bolt pieces together

Step 4: Prepare Hydraulic Cylinder

Diagram and video explantion

This diagram shows the pieces needed for the frame. Click to enlarge:

- [4] 21" long - top and bottom of frame

- [2] 29" long - mid of frame

- [2] 10" long - compression chamber spacers

- [2] 42" long - frame sides - see Note on CEB Frame Height

- [2] 44" long - frame sides - see Note on CEB Frame Height

- [4] 6' long - arms

- [4] 4' long - legs

- [4] 6" long - 2.5"x3/16" square tubing - feet tubes

- [4] 10"x10"x1/4" flats - feet

- [2] 1/4"x2" angle, 21" long - hopper closure

- [2] 1/4"x2" angle - 7" long - hopper closure tab for cylinder alignment

Drawer

Hopper

- Plasma cut sheet metal

- Punch 3/4" holes in all 28 hinges, in center of rounded part

- Punch holes in hopper sheet metal (all the blue holes, 3/4")

- Bolt all hinges to sheet metal at the red locations marked "1" with 3/4" bolts

- Weld bottom hinges of hopper sheet 1 to hopper mount plate

- Weld top hinges of hopper sheet 1 to grate

- Install hopper supports to hold hopper sheet 1, and bolt with the 2 bolts (1/2")

- Weld hinges to hopper supports for sheet 2

- Weld hinges at base of sheets 2, 3, 4

- Weld hinges between sheets 3&1, 4&1, and between 2&3, and 2&4

- At this point, the entire hopper is erected. It remains to weld the remaining hinges to the grate.

- Upon completing these steps, the 3/4" bolts can be replaced with 1/2" bolts for successive deconstruction and reconstruction of the hopper.

hopper supports

shaker

hopper interface plate

- [2] 3/4" pipe, 1" long - cylinder aligner

- [2] u-channel, 3" - cylinder align