Torch Table Specifications: Difference between revisions

Jump to navigation

Jump to search

(New page: =General= *Consists largely of off-shelf components and stock steel profiles for structure *Materials cost of $1500 *1/16" accuracy over 8 feet *1/50" resolution *30 pounds of force on x ...) |

|||

| (One intermediate revision by the same user not shown) | |||

| Line 8: | Line 8: | ||

*Single side drive | *Single side drive | ||

*Simplest possible design for fabrication optimization | *Simplest possible design for fabrication optimization | ||

*Accepts oxyacetylene or plasma torch head | |||

=Images= | =Images= | ||

| Line 25: | Line 26: | ||

. | . | ||

[[Image:torchtablesimple4.jpg]] | [[Image:torchtablesimple4.jpg]] | ||

[[Category:Specifications]] | |||

Latest revision as of 21:11, 3 March 2009

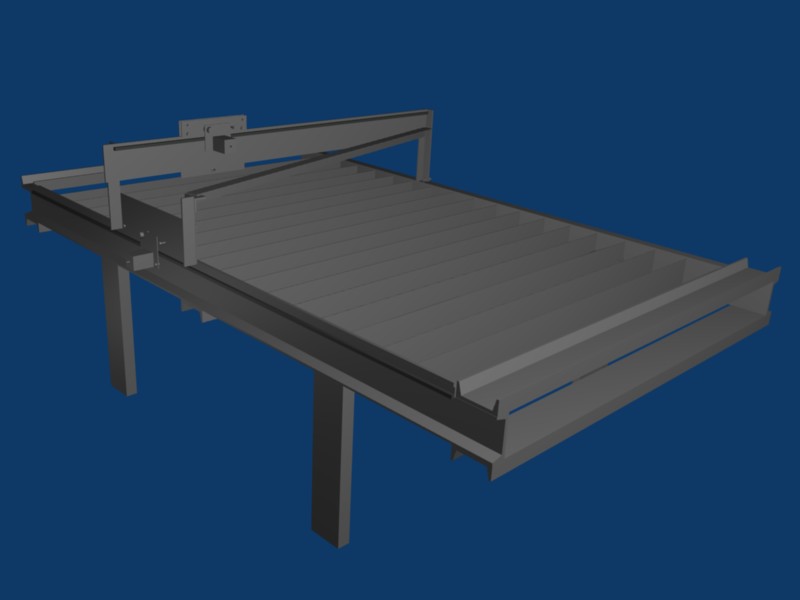

General

- Consists largely of off-shelf components and stock steel profiles for structure

- Materials cost of $1500

- 1/16" accuracy over 8 feet

- 1/50" resolution

- 30 pounds of force on x and y axis

- Single side drive

- Simplest possible design for fabrication optimization

- Accepts oxyacetylene or plasma torch head

Images

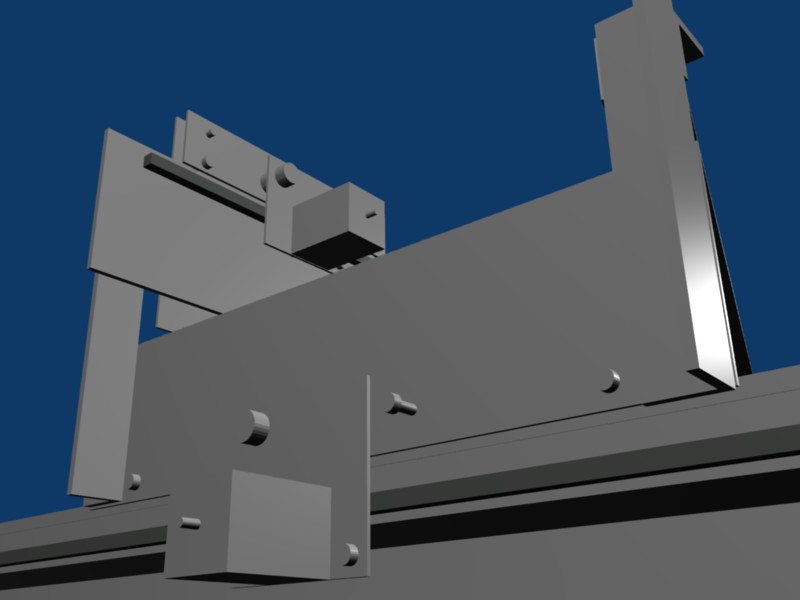

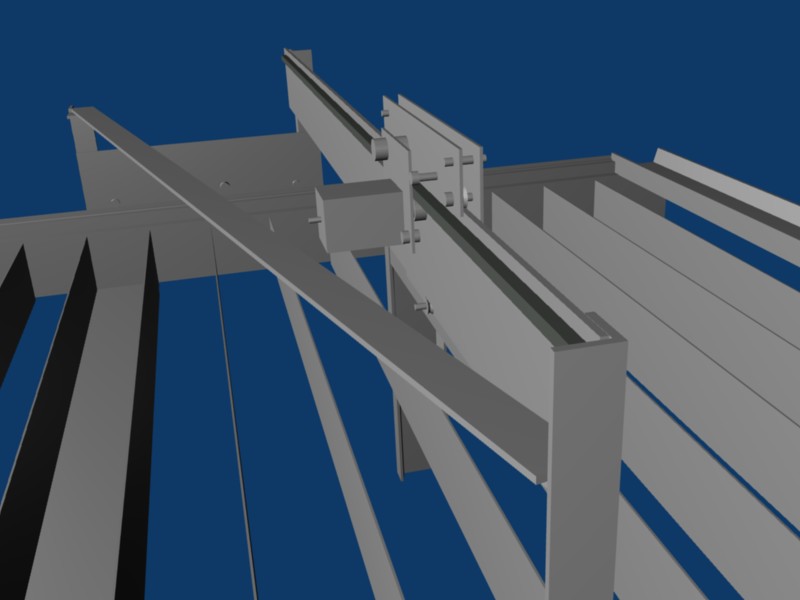

X Axis Detail

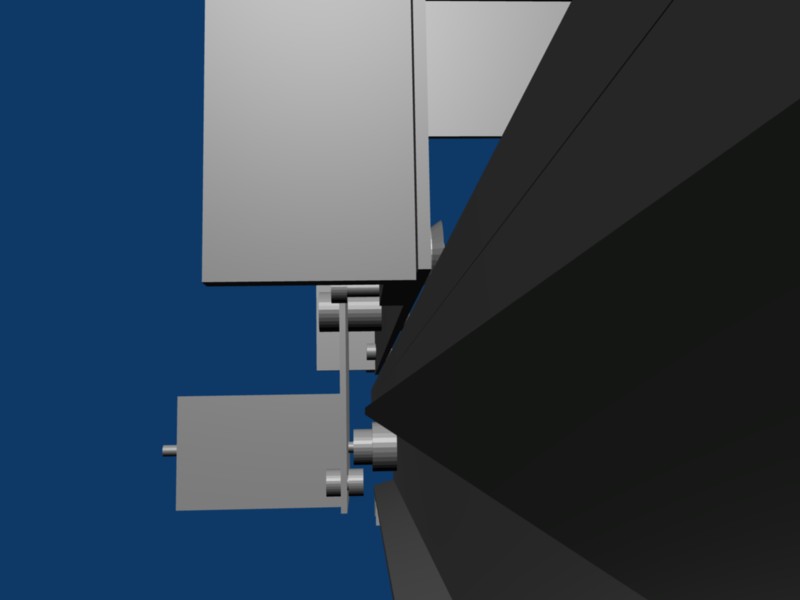

Note a 1 1/4 inch square cold-rolled rail, to which a gear rack is attached. A small angle holds the roller cam on top of the cold-rolled rail.

Gear rack is attached to cold rolled rail. Spring tensioning of stepper motor plate is used. Stepper motor plate is attached to the gantry through a bearing to allow rotation, for spring tensioning

.