Chris Bassett Log: Difference between revisions

(Created page with " == Summary: == This page is for the purpose of documenting the work done by Chris Bassett on the Open Source Ecology project CNC-torch table. Chris Bassett is a mechanical ...") |

No edit summary |

||

| Line 1: | Line 1: | ||

== '''Chris Bassett Log''' == | |||

== | |||

'''7/13/2013''' | '''7/13/2013''' | ||

Design Sprint. Set Goals to work out details of acetylene/oxygen controls between tanks and torch head (Gas Delivery System). Review mechanics of slider gantries on table in solidworks. | Design Sprint. Set Goals to work out details of acetylene/oxygen controls between tanks and torch head (Gas Delivery System). Review mechanics of slider gantries on table in solidworks for design considerations. | ||

== '''7/15/2013''' == | |||

'''7/15/2013''' | |||

Learned out to work GIT HUB to access file repositories. Need to download application. A tutorial can be found here: | Learned out to work GIT HUB to access file repositories. Need to download application. A tutorial can be found here: | ||

https://help.github.com/articles/fork-a-repo | https://help.github.com/articles/fork-a-repo | ||

The application can be found here: | The application can be found here: | ||

https://help.github.com/articles/set-up-git | https://help.github.com/articles/set-up-git | ||

| Line 27: | Line 16: | ||

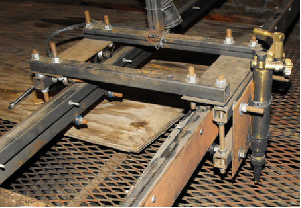

Will build upon prior torch mounting systems of hose clamps holding a modified torch head. | Will build upon prior torch mounting systems of hose clamps holding a modified torch head. | ||

Learned the stepper motors move the gantry using rack and pinions. | Learned the stepper motors move the gantry using rack and pinions. | ||

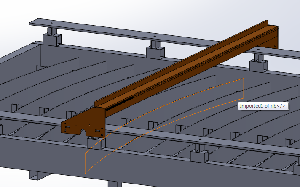

The prior flying gantry used two rails in parallel to stabilize rotation. From the model, v2 of the Torch the flying gantry will slide on one rail so some suitable bracking will need to happen. | The prior flying gantry used two rails in parallel to stabilize rotation. From the model, v2 of the Torch the flying gantry will slide on one rail so some suitable bracking will need to happen. | ||

[[File:gantry v1.jpg]] [[File:gantry v2.jpg]] Changes to consider in tool head design. | |||

Standards for oxy-acetylene systems: | Standards for oxy-acetylene systems: | ||

Revision as of 01:30, 16 July 2013

Chris Bassett Log

7/13/2013 Design Sprint. Set Goals to work out details of acetylene/oxygen controls between tanks and torch head (Gas Delivery System). Review mechanics of slider gantries on table in solidworks for design considerations.

7/15/2013

Learned out to work GIT HUB to access file repositories. Need to download application. A tutorial can be found here: https://help.github.com/articles/fork-a-repo

The application can be found here: https://help.github.com/articles/set-up-git

Checked that the solid works file loaded - successful. Will review in detail later

Researched Prior Work. Will build upon prior torch mounting systems of hose clamps holding a modified torch head. Learned the stepper motors move the gantry using rack and pinions.

The prior flying gantry used two rails in parallel to stabilize rotation. From the model, v2 of the Torch the flying gantry will slide on one rail so some suitable bracking will need to happen.

Changes to consider in tool head design.

Changes to consider in tool head design.

Standards for oxy-acetylene systems: Threading is 1/4 NPT, LH threading for acetylene connections. Valves should be "grease-less" for prevention of combustible contaminants

Solenoid For Cutting Oxygen Flow: http://www.mcmaster.com/#standard-brass-solenoid-valves/=nmzf4c