Micro Power Cube: Difference between revisions

Tom Griffing (talk | contribs) |

Tom Griffing (talk | contribs) (→Design) |

||

| Line 98: | Line 98: | ||

I've done a Sketchup of the initial design, for reference. Any feedback would be appreciated. | I've done a Sketchup of the initial design, for reference. Any feedback would be appreciated. | ||

[ | [[Image:SmallPowerCube.jpg Small Power Cube]] | ||

Revision as of 13:49, 28 March 2014

Communications

From Stefan:

I remember mentioning "brushless outrunners". A cheap source is Hobbyking (They also have US warehouses but it's not immediately obvious how to order from them):

http://hobbyking.com/hobbyking/store/__517__59__Electric_Motors-Outrunners_by_size.html

These motors have no mechanical commutator and need a driver:

http://hobbyking.com/hobbyking/store/__61__182__Speed_Controllers-All_Speed_Controllers.html

These RC drivers are controlled like any RC servo which means you can use the Arduino servo example to get started.

Tom Griffing

Marcin Feedback

Tom,

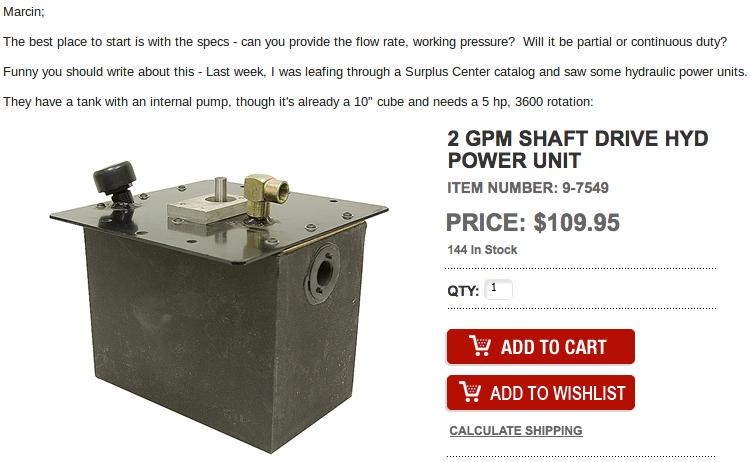

It appears that the industry standard is dunking the hydraulic pump right in the reservoir. How Clever!

You are right about requirements. Here they are:

- Audience: the hacker in a hackerspace who wants to add hydraulic power to their skillset, or the custom fabricator or any producer looking for a small hydraulic power solution.

- External electric source

- Entire assembly is one cubic foot or less

- Weight is under 25 lbs

- May be used for powering LifeTrac and in shearing 1"x8" slabs of mild steel with an Ironworker machine.

- GPM - 1

- Reservoir - 1 gallon

For the elite hacker crowd, I think making this thing as small as possible would make it not only more manageable but also less intimidating.

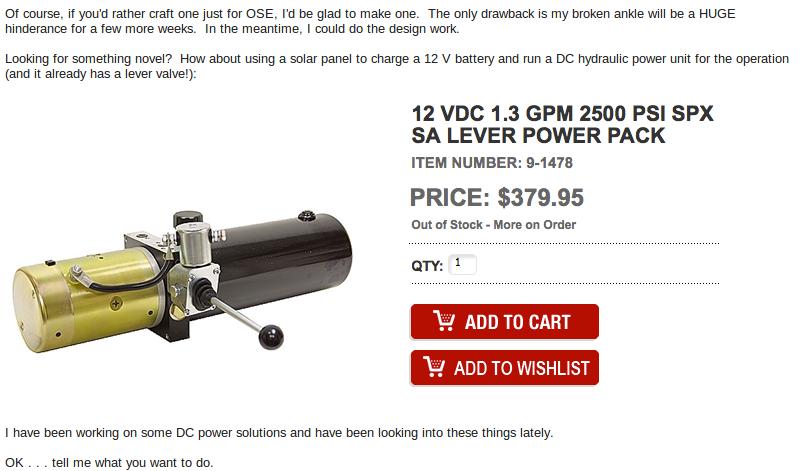

I imagine the first option above ($109) with a tiny 2 kW electric motor, with 4x geardown, so that it's matched to driving the motor, but at slightly reduced output. The main challenge will be to not burn out the electric motor.

See this motor - [1]. Motor needs a driver and controller to run - see comment from Stefan above.

Motor RPM is 9120 at 24V from its specs. If the above hydraulic unit without motor is designed for 5 hp drive at 3600 RPM - we have only 2kW =2.7 hp - or about half the required power. So to not burn out the electric motor, we want gear reduction factor of 9120/3600 x2 = 5.1 gear reduction.

If the power unit costs $109 minus the driving motor - motor is $41 + controller + geardown - should be around $300 total.

MJ

Can we do this?

- - - - -

I think so, but it will take some adjustments.

The reservoir above ($110) will work. It is geared to deliver 2 GPM at 5 HP, so running it at half that power should deliver 1 GPM (2000 Watts / 746 = 2.68 HP).

I'll have to investigate the motor ($41), as I have concerns about startup torque, as it is purposed for low-torque applications - even if geared 3:1. The hydraulic pump requires the most torque at start-up (extra torque for spin-up to operating speed and hydraulic fluid is thick when cold).

The controller ($100) is the smallest offered with 90A capability (actually: 100A). I have an Arduino development kit for stepper motors and have used it to drive various motors, but at less than 10A. I'd suggest replacing it with a 120 VAC motor if possible (no power supply or controller needed). I'll look into both options.

The power supply should deliver 22 - 30 Volts @ 90A. For size and weight, it should be a switching power supply. 24V is a common voltage and I've found a lot of them, but only one capable of 90A. It's looks big, heavy and costs $200. I'll look for other options. [2]

The filter ($12) is the smallest offered by Surplus Center.

Belt, pulleys, hydraulic connections to be added.

- PARTS -

Power One 12V, 50 / 100A or 24V 50A 2000W Dual Output DC Power Supply 110 / 220V $199.99

2 GPM SHAFT DRIVE HYD POWER UNIT item number: 9-7549 PRICE: $109.95

3/8" NPT 7 GPM RETURN LINE FILTER item number: 9-7291 PRICE: $11.95

NTM Prop Drive 50-60 Series 380KV / 2665W

Turnigy Super Brain 100A Brushless ESC Speed Controller

I'll keep looking.

Tom

Design

I've done a Sketchup of the initial design, for reference. Any feedback would be appreciated.