Solar Village 2010: Difference between revisions

Jump to navigation

Jump to search

(→Steps) |

(→Steps) |

||

| Line 29: | Line 29: | ||

##Truss preparation | ##Truss preparation | ||

##Test stabilized bricks | ##Test stabilized bricks | ||

##Test reject lime-cement bricks | ##Test reject lime-cement bricks | ||

##Air-powered water pump | ##Air-powered water pump | ||

Revision as of 23:18, 28 March 2010

Steps For Building a Solar Structure

Review of concept to date:

- CEB walls

- Straw bale infill between 2 wall cavities

- House-integrated CEB stove

- Thermaclear or Solexx glazing

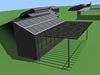

- Structure similar to

but solar cover extends from green roof

but solar cover extends from green roof - Greenspace

- Green roof

- Trellis for solar shade in summer

- Trellis is covered partly with roofing material with solar angle to allow for solar gain only in winter

- Rest of trellis will be growing grapes

- Composting toilet

- CEB floor

- Side space covered for rooftop rainwater catchment and CEB water cistern

- Planter in front and sides - zone 0 plantings in planter

- Keyhole garden

Steps

- Site prep - flatten site with front loader and blade

- Build blade

- Build LifeTrac II

- Build sawmill

- Building material prep

- Rollers

- Sawmilling in July

- Truss preparation

- Test stabilized bricks

- Test reject lime-cement bricks

- Air-powered water pump

Summary: May will be heavy equipment building time, and June-July will be shakedown of all the building equipment, techniques, water system and site prep, and production of materials (lumber, brick, mortar). August 1 - house is going up.

Uniqueness summary: LifeTrac II, Sawmill, Air powered water pump, CEB stove, CEB floor, OS blade, PowerCube II, CEB-Straw Bale hybrid

Timeline

- April 15-30 - Dimensional Sawmill Prototype design

- Assuming 1 CEB presss production

- May 1-31 - Build LifeTrac II, PowerCube II, build Sawmill, build leveling blade, build LifeTrac wheel tracks if budget allows

- June - July - Cut lumber, test stabilized and lime bricks, do the well pump and prepare water lines, site preparation, build trusses, prepare brick rollers

- Test whether water-sraying between courses works (so called 'dry stacking'), or, prepare slurry mixing equipment (either 55 gal drum or 200 gal container)