PVC Pipe and Fittings Library: Difference between revisions

(remove parts which belong to OSE_piping_workbench) |

|||

| Line 3: | Line 3: | ||

This is a library of all the current PVC Pipe and Fittings that have been made in freecad for OSE. Many fittings can be created using [[#OSE Piping Workbench]]. | This is a library of all the current PVC Pipe and Fittings that have been made in freecad for OSE. Many fittings can be created using [[#OSE Piping Workbench]]. | ||

= | = Pipe dimensions used in literature = | ||

* O.D. - outer diameter. | * O.D. - outer diameter. | ||

* Average I.D. - average inner diameter (why average?). This dimension determines the size of the pipe. | * Average I.D. - average inner diameter (why average?). This dimension determines the size of the pipe. | ||

| Line 26: | Line 9: | ||

* Schedule - determines (indirectly) the thickness of the wall. | * Schedule - determines (indirectly) the thickness of the wall. | ||

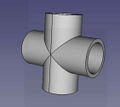

= Cross = | = Cross = | ||

| Line 97: | Line 17: | ||

[[File:cross-dimensions.png]] | [[File:cross-dimensions.png]] | ||

=Genaerated Library Parts= | =Genaerated Library Parts= | ||

| Line 177: | Line 78: | ||

[[File:OsePiningWorkbenchScreenshot.png|600px]] | [[File:OsePiningWorkbenchScreenshot.png|600px]] | ||

| Line 211: | Line 86: | ||

*: Yes. For high pressure applications - 300 PSI - we would have to be very careful. For low pressure, such as 5 PSI, it's not a problem. Eventually, we want to refine printing techniques where our fittings can do what standard schedule 80 ABS fittings can do. | *: Yes. For high pressure applications - 300 PSI - we would have to be very careful. For low pressure, such as 5 PSI, it's not a problem. Eventually, we want to refine printing techniques where our fittings can do what standard schedule 80 ABS fittings can do. | ||

** Also with things such as part baking/anealing, composite filaments, and SLA or SLS Printers, very durable parts can be made | ** Also with things such as part baking/anealing, composite filaments, and SLA or SLS Printers, very durable parts can be made | ||

| Line 219: | Line 91: | ||

* | * | ||

Revision as of 09:57, 30 March 2018

Basics

This is a library of all the current PVC Pipe and Fittings that have been made in freecad for OSE. Many fittings can be created using #OSE Piping Workbench.

Pipe dimensions used in literature

- O.D. - outer diameter.

- Average I.D. - average inner diameter (why average?). This dimension determines the size of the pipe.

- Min. Wall - thickness of the pipe wall.

- Schedule - determines (indirectly) the thickness of the wall.

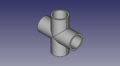

Cross

Almost General Cross

A cross is described by dimensions G, G1, G2, G3, H, H1, H2, H3, M, M1, and pipe dimensions. As pipe dimensions we use POD, POD1, PID, and PID1.

Genaerated Library Parts

SCH40 1" PVC pipe - size:5kb - FreeCAD -File:Pipe-test.fcstd,

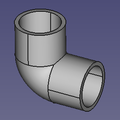

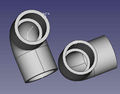

Elbow test file. Here alpha° is 45°. - size:21kb - FreeCAD -File:Elbow-test.fcstd,

1"-1/2" coupling test file - size:17kb - FreeCAD -File:Coupling-test.fcstd

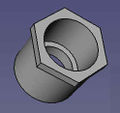

1"-1/2" bushing - size:21kb - FreeCAD -File:Bushing-test.fcstd

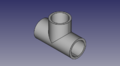

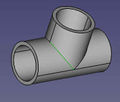

1" tee test file - size:28kb - FreeCAD -File:Tee-test.fcstd

1" cross test file - size:34kb - FreeCAD -File:Cross-test.fcstd

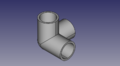

1" outer corner test file - size:30kb - FreeCAD -File:Corner-test.fcstd

Library of STEP Downloads from McMaster Carr

Comparable in size to generated parts - except for some parts which are way too heavy.

1" PVC Elbow - size:19kb - FreeCAD -File:1"-pvc-elbow.fcstd,

1" PVC Tee - size:25kb - FreeCAD -File:1"-pvc-tee.fcstd,

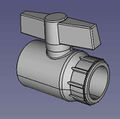

1" PVC Valve - size:500kb - FreeCAD -File:1"-pvc-valve.fcstd,

1"-3/4" PVC Bushing - size:13kb - FreeCAD -File:1"-34"-reducer.fcstd,

1" PVC Cross - size:13kb - FreeCAD -File:1"-cross.fcstd,

2" PVC Elbow - size:157kb - FreeCAD -File:2"-elbow.fcstd,

- 2"-tee.jpg

2" PVC Tee - size:8kb - STEP -[1] - FreeCAD - File:2"-pvc-tee.fcstd

- 2"-tee-short.jpg

2" PVC Tee - Short Nonstandard - size:4kb - STEP -[2] - FreeCAD - File:2"-pvc-tee-short.fcstd

- 2"-3"-bushing.jpg

2"-3" bushing - size:161kb - STEP -[3] - FreeCAD - File:2"-3"-bushing.fcstd

- 3"-2"-reducer.jpg

2"-3" reducer. Note difference between a reducer and a bushing (last one) - size:161kb - Menards -[4] - FreeCAD - File:3"-2"-reducer.fcstd

- 3"-2"-reducer.jpg

2"-1" reducer. - size:10kb - STEP -[5] - FreeCAD - File:2"-1"-PVC-reducer.fcstd

OSE Piping Workbench

Implemented are:

- pipe

- coupling

- bushing

- elbow

- tee

- cross

- outer corner

FAQ

- Do we really want to 3D-print pipe fittings? Somehow I have doubt about mechanical properties of the 3D-printed products.

- Yes. For high pressure applications - 300 PSI - we would have to be very careful. For low pressure, such as 5 PSI, it's not a problem. Eventually, we want to refine printing techniques where our fittings can do what standard schedule 80 ABS fittings can do.

- Also with things such as part baking/anealing, composite filaments, and SLA or SLS Printers, very durable parts can be made

See Also