Open Source 3D Printing Cluster: Difference between revisions

| Line 68: | Line 68: | ||

*[[Open Source Digital Fabrication Construction Set]] | *[[Open Source Digital Fabrication Construction Set]] | ||

*[[D3D Printer]] | *[[D3D Printer]] | ||

*[[3d Printer Cluster]] | *'''[[3d Printer Cluster]]''' | ||

Revision as of 20:38, 7 April 2018

Introduction

This project is intended to be a Distributive Enterprise which allows for a cloud-based 3D printing service. Payment is included in this service.

OSE Implementation

![]() Hint: See 3D Printer Cluster for OSE's implementation started by Christian Log

Hint: See 3D Printer Cluster for OSE's implementation started by Christian Log

Used For

- 3D Pronting of parts

- as a component of the Open Source Automation Construction Set

Development

Team

See Christian Log for July 2017 entries.

Working Doc

Cluster Features - Requirements

- Control of 24 printers with one raspberry pi

- Logging of total print time for every machine

- Logging of total number of prints

- Logging of print failure. Suggestions - upon starting a print on a given machine, you are asked whether the last print was successful.

Phases

- 1 - printing, 12 printers

- 2 - Online Ordering of 3D Prints. Software activates printer automatically, and prints shipping label automatically. Shipping via Pickup. Automatic print labels.

- 3 - Integration with postage printing.

- 4 - Addition of Stickers printed on demand.

- 5 - Open source color laser printer and inkjet printer.

Industry Standards

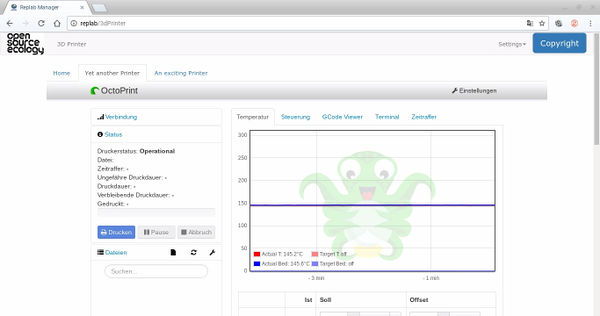

- Polar Cloud - https://polar3d.com/ - Cloud 3D print platform; proprietary, but uses open source OctoPrint.

- Prusa's Latest Print Farm

Minimum Viable Product

- Open Source

- Modular

- User Maintainable

- User Upgradable

- Uses the D3D Printer (although this could be adapted to other machienes in the Open Source Digital Fabrication Construction Set

- Diverse Networking Options (ie USB, Thunderbolt 3, Ethernet, Infiniband, Wifi, Bluetooth, Lifi)

- Scalable From 2 Printers to 1,000 Printers (maybe more...)

- Intigration with the Open Source Automation Construction Set

- User Freindly

Basic Design

Printer

- D3D Printer (Although others could possibly work with the software+any additional hardware too)

Hardware

- Something like a rasberry pi/mini PC (or custom board) takes in the network signal, then this passes it off to the printer's microcontroller+servo controller via USB

- Because it is usb connected and not soldered in this allows for easy upgradability, and modularity

- This could all go in a 3D Printed Enclosure

Communications

4.7.18

To Chris Rupp - I'm working on the print cluster - and it appears that Octoprint does not support SD card printing, but only streaming from the Raspberry Pi. I have not found any source showing how to use an SD card to store the print file - it appears that the standard route is streaming from the Pi to the 3D printer. Is that so, or am I mistaken?

This is important because, say we have 6 printers connected to a Raspberry Pi - we don't want 6 of them to fail if the Pi crashes. We need to have this designed such that each printer is running from its own SD card - and can finish a print job even if the server fails. This limits failure modes to only power outages on the 3D printer itself - which is also addressable in the future.

I am exploring different possible configurations - and am questioning our prior route because of the issue in this email. -MJ