Angle Frame Connector: Difference between revisions

Jump to navigation

Jump to search

| Line 27: | Line 27: | ||

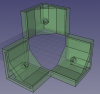

*STL - sunk 5 mm into bed. 50% infill, 10:10 hours, 133 g | *STL - sunk 5 mm into bed. 50% infill, 10:10 hours, 133 g | ||

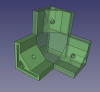

[[File:cornerproductionengineering.png| | [[File:cornerproductionengineering.png|500px]] | ||

Revision as of 20:36, 7 October 2019

CAD

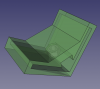

Angle Connector. - FreeCAD with McMaster 6 mm nut -File:Angleconnector.fcstd. Finished STL - File:Anglecorner.stl

Concept

Production

- 50% infill for real print.

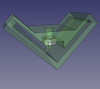

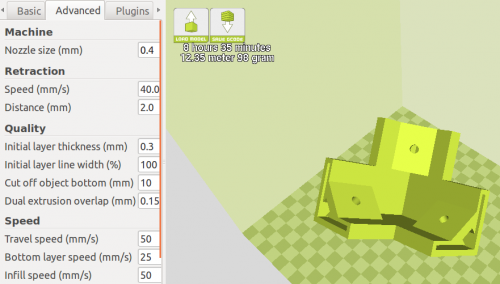

- Test print at 20%: 10 cm cut off the bottom, standing on corner - . This would not stand on moving-bed printers. Babystepping correction -0.75. It does not stand on a stationary bed printer eiether. I turned it around to print standing on 6 points.

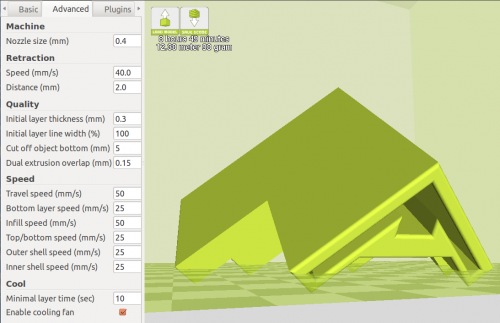

- Came off bed so printed it on 6 corners:

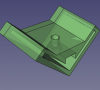

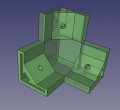

- Initial fit: metal shown with 6 mm hex nut and set screw in the hole.

- STL - sunk 5 mm into bed. 50% infill, 10:10 hours, 133 g