Open Source Battery Pack: Difference between revisions

m (→Concept) |

|||

| Line 2: | Line 2: | ||

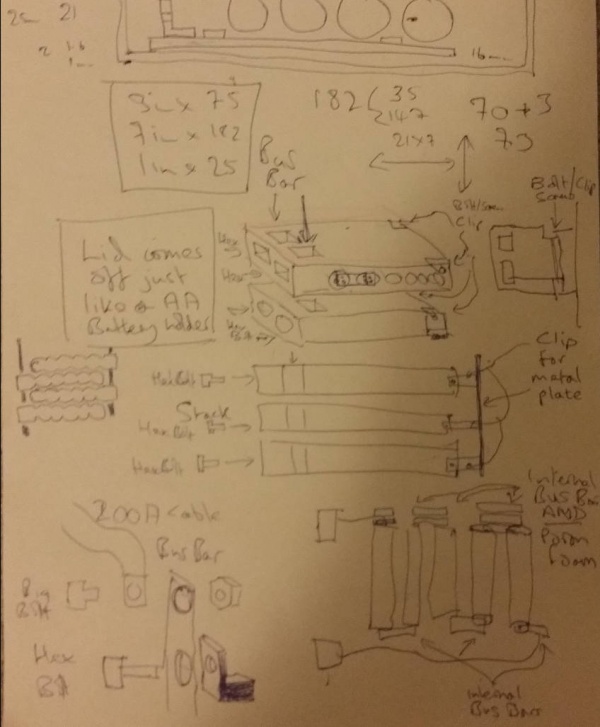

[[File:openbms.jpg|600px]] | [[File:openbms.jpg|600px]] | ||

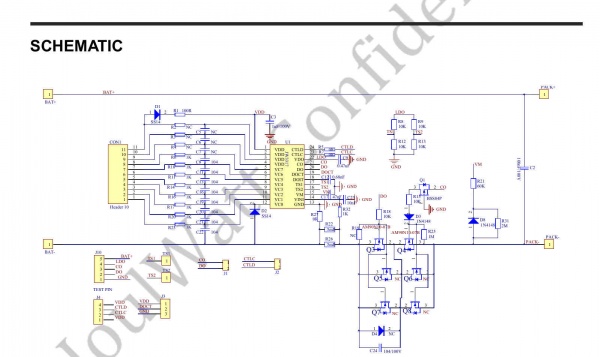

=JW3317 BMS schematic (1) | =JW3317 BMS schematic (1)= | ||

[[File:jw3317.jpg|600px]] | [[File:jw3317.jpg|600px]] | ||

Revision as of 21:58, 31 December 2019

Concept

JW3317 BMS schematic (1)

Description

Based on existing open (non-libre) designs, this is a 5-cell (18650) 18v battery holder similar to a "AA" battery holder, designed to connect safely and easily with bus-bars into larger high-ampage packs, where every single cell is individually protected from charging and discharging damage and over-current or short-circuiting. They are also designed to stack together where the cells are hexagonally overlapping, saving some space.

The recommended BMS for the "really simple" version uses the China-made JW3317 https://www.aliexpress.com/item/4000052402113.html where the absolute-minimal schematic and "datasheet" is available here: https://www.joulwatt.com/en/proinfo_3488.html

The actual cells are visible from both the top and bottom. This has the side-effect of making it easy to assemble, inserting Bus-Bars into the 3D-printed plastic. Internal nickel-copper-plated Bus-bars backed with poron foam as an easy-to-construct spring create a high-ampage contact between cells, where the BMS wires may easily be soldered to each Bus-Bar rather than to the 18650 cells themselves (causing damage and inability to replace the cells). At one end the internal bus-bars slot firmly into the lid, where at the other end they are embedded into the plastic with poron foam behind them.

The BMS circuit sits at an angle inside the 3D-printed pack, to save space. The battery wires (12 guage, 25A) connect to large upright metal squares that have a screw-hole through the middle. These squares are embedded firmly into the 3D printed plastic. From the top, through a hole that goes right the way through the pack, small enough to not permit fingers to get into, *external* Bus-Bars with over-sized holes in them are "dropped" then, on proper alignment, screws inserted that lock the external Bus-Bars into place.

The external Bus-Bars also therefore act as a mechanical means of holding multiple packs together. To save space, rather than have extra screw-holes at the other end, the packs can be slotted together (interleaved) with a hexagonal cell-overlap, such that if four or more packs are assembled together, the external Bus-Bars at each end help clamp and support the entire block. With the hexagonal overlap and the screws holding every pack onto two Bus-Bars there is simply no way to pull the packs apart.