Melt Blown Plastic: Difference between revisions

Jump to navigation

Jump to search

| Line 13: | Line 13: | ||

=Feasibility Study= | =Feasibility Study= | ||

What technology is required to produce the machine? | What level of technology is required to produce the machine? | ||

#Precision die with small holes | #Precision die with small holes | ||

#Near-sonic air flow | #Near-sonic air flow | ||

Revision as of 23:16, 23 March 2020

Basics

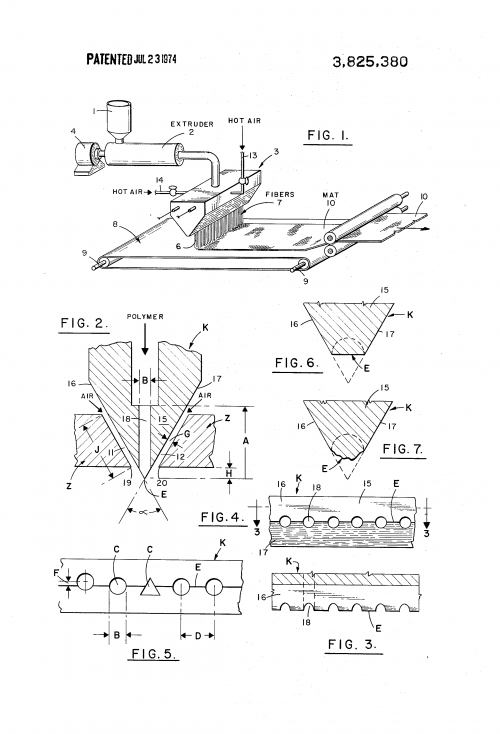

- A Process for Manufacturing Nonwoven Fabric of a very fine nature

- Used mainly for filters, but also has many other applications

- Not to be confused with Blow Molding

- Uses fine nozzles for plastic which are surrounded by high velocity air to essentially atomise it

- Melt-blown plastic is a material for making N95 masks, or HEPA filters as well.

- Similar Processes are used for Fiberglass, Basalt Fiber...And Cotton Candy, although this is typically done with a linear, rather than radial output (see the patent section)

Patents

- Melt-blown plastic, original Exxon patent - [1]

Feasibility Study

What level of technology is required to produce the machine?

- Precision die with small holes

- Near-sonic air flow

- Hot air generation