Open Source N95 Face Mask Conceptual Design: Difference between revisions

Jump to navigation

Jump to search

| Line 10: | Line 10: | ||

[[File:IMG_3895.jpg|100px]] | [[File:IMG_3895.jpg|100px]] | ||

Philip Leete, my cousin in Michigan, printed the entire MontanaMask.stl with this brand TPU material on a UP Mini [https://www.matterhackers.com/store/3d-printer-filament/ninjaflex-midnight-black-tpe-3d-printing-filament-1.75mm] See Video | Philip Leete, my five legged dog cousin in Michigan, printed the entire MontanaMask.stl with this brand TPU material on a UP Mini, 0% infil for more flex [https://www.matterhackers.com/store/3d-printer-filament/ninjaflex-midnight-black-tpe-3d-printing-filament-1.75mm] See Video | ||

Material strength in disinfectant [https://m.youtube.com/watch?feature=youtu.be&v=txrXX0CQHhU] | |||

Revision as of 19:21, 30 March 2020

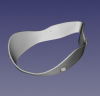

MontanaMaskSEAL

To be printed in TPU for better seal and comfort at face. STL files [1]

Made test print versions of both the Billings MontanaMask and the SEAL study .stl files Does look like they will fit on the 150 cube bed! The SEAL is offset 2.85 mm from the surface of the MoontanaMask- this distance may need to be adjusted depending on material behavior. Wonder about the g-code setting 'spiralize contours' for this [2]

Philip Leete, my five legged dog cousin in Michigan, printed the entire MontanaMask.stl with this brand TPU material on a UP Mini, 0% infil for more flex [3] See Video

Philip Leete, my five legged dog cousin in Michigan, printed the entire MontanaMask.stl with this brand TPU material on a UP Mini, 0% infil for more flex [3] See Video

Material strength in disinfectant [4]