Open Source Lathe: Difference between revisions

Jump to navigation

Jump to search

| Line 1: | Line 1: | ||

=Introduction= | =Introduction= | ||

Here we are showing the details for fabricating a high-performance (2/1000" accuracy), high power (20 hp) lathe. It will be powered from the hydraulic take-off from a tractor - [[LifeTrac]]. | Here we are showing the details for fabricating a high-performance (2/1000" accuracy), high power (20 hp) lathe. It will be powered from the hydraulic take-off from a tractor - [[LifeTrac]]. The design follows that of the [http://opensourcemachine.org/the-multimachine/multimachine-video Multimachine]. Instead of an engine block as the basic structural unit, we'll be using a concrete bed with metal mounting plates. | ||

=Design Rationale= | =Design Rationale= | ||

Revision as of 21:08, 28 January 2009

Introduction

Here we are showing the details for fabricating a high-performance (2/1000" accuracy), high power (20 hp) lathe. It will be powered from the hydraulic take-off from a tractor - LifeTrac. The design follows that of the Multimachine. Instead of an engine block as the basic structural unit, we'll be using a concrete bed with metal mounting plates.

Design Rationale

- High power, simple design

- OSE Specifications are met via low cost for replication; a transparent, open source development process; open documentation; product evolution infrastructure

- External power source

- Interchangeable motor - part of LifeTrac infrastructure, motor can be coupled to many different devices

- Hydraulic motor provides high power and torque with full speed control via a flow control valve

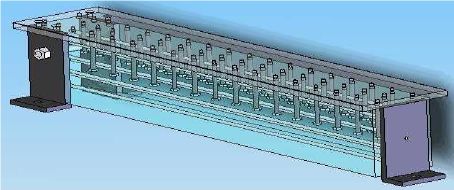

- Basic design is two bearings with bearing clamps holding bearings in place:

Chuck

We will fabricate a chuck from a 1" steel pate, as in:

Cross Slide

For the lathe to be able to handle large work pieces, the cross slide itself - which holds the tool post.

Tool Post

The tool post will have to mount securely to the cross slide.

Motor

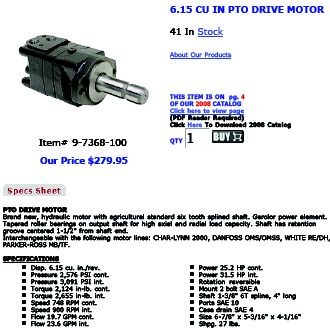

Brute 20 horse of turning power is provided by a hydraulic motor powered by LifeTrac

Shaft Coupler from motor to shaft

Bill of Materials - Lathe

- Romig bed lathe type - from Multimachine -

- Simple prototype, $486 in materials BOM:

- 2 bearings, $50

- 2 mouning plates, 1/2"x6" angle - $40

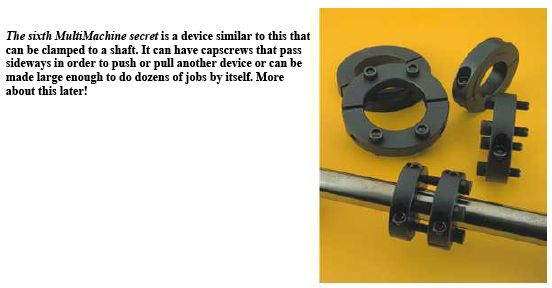

- 4 Shaft Collars - $20

- 2" shaft - $20

- DOM tubing, 3", 2" ID - $15

- 8 3/4" bolts for table - $16

- Chuck plate - $40

- Bolts for chuck - $20

- Nuts and bolts for DOM - $5

- XY table - $70 off shelf at Enco - [1]

- Tool post - $10

- table plate - $30

- 2 bags of cement, 80 lb each - $20

- sand, gravel - $10

- TOTAL - $316

- High performance, 2/1000" accuracy with proper technique, stock parts, 1000 lb radial and 200 lb axial load capacity

- Romig bed lathe type - from Multimachine -