CEB Design: Difference between revisions

Jump to navigation

Jump to search

m (→Overview) |

|||

| Line 96: | Line 96: | ||

==See Also== | ==See Also== | ||

[[CEB_Press/Research_Development |CEB Press | [[CEB_Press/Research_Development |CEB Press Resarch & Development]], [[CEB_Press/Research_Development/Controller_Design |Controller Design]], [[CEB_Press/Research_Development/Hydraulic_Design |Hydraulic Design]] | ||

{{CEB}} | {{CEB}} | ||

[[Category:CEB_Press]] | [[Category:CEB_Press]] | ||

Revision as of 00:46, 3 July 2012

Overview

CEB Press Design

CEB Press Design

Components

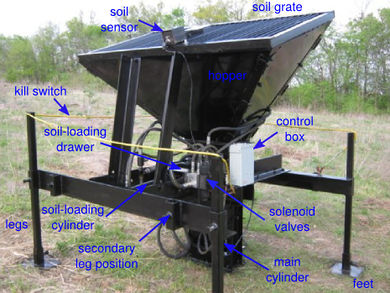

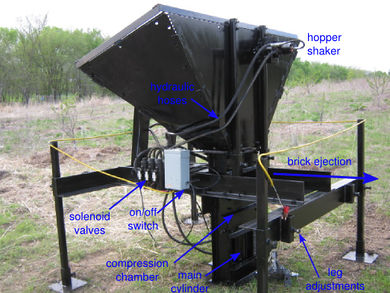

The Liberator consists of -

- A Hopper at the top which you fill with loose dirt. This is made from welded steel. We made the hopper six feet wide, so it can hold a lot of dirt.

- Grate and grate shaker - the grate is at the bottom of the hopper. The grate shaker shakes it so that soil falls through into the compression chamber, while large stones and things like that are caught in the grate.

- A frame that bolts together for easy assembly and disassembly.

- A compression chamber where the bricks are actually pressed. This is a metal box with a nylon liner bolted on the inside. The liner gives the bricks a smoother finish. It will have to be replaced every hundred thousand bricks or so.

- Hydraulic cylinders - These are the muscles of the machine; they apply the pressure to the dirt. They are readily removable with pins. There are two hydraulic cylinders:

- The soil drawer - this moves from left to right and performs the dual function of loading soil into the compression chamber and ejecting blocks from the machine

- The main cylinder, which moves up and down and compresses the blocks

- Tractor mount, where an external hydraulic power source can be attached to the hydraulic cylinders.

- Pressure gauge, which monitors the amount of pressure used by the hydraulic system to ensure a certain density of brick.

- Controller Box controls the timing and sequence of operations.

Specifications

| Bricks per minute output | 16 |

|---|---|

| Brick size | 12x6x6 inches (30.5x15.3x10.2 cm) |

| People operating machine | 1-2 |

| Power source | Tractor hydraulics or any hydraulic power source with 6 gallon per minute capacity (22.71 liters per minute) |

| Machine mounting | tractor 3 point hitch or stand-alone foot |

| Hydraulic pressure | 2000psi / 137.90 bar |

| Hydraulic cylinder | 5 inch diameter, 19.6 inch area; 2.5 inch rod |

| Pressing cylinder pressure | 39,250 lb pushing force (~18 tons) |

| Controls | 2 spool, manual, hydraulic valve; automatic version forthcoming. |

| Compressive strength of bricks | 795psi (54.81 bar) using plain earth. 1200psi (82.74 bar) with 10% Portland cement. Strong enough to build a 60-story building [1] |

| Materials: | Structural cold rolled steel construction throughout |

| Height: | 6 foot 11 inches/ 210.82 cm |

| Machine lifetime goals: | 1 million bricks before repairs; liner may be replaced every 100,000 bricks |

| Fabrication time requirement for optimized production: | 3-5 days, about 20 hours of direct fabrication |

| Manual fabrication tooling requirements: | drill press, welder, acetylene torch |

| Optimal fabrication tooling: | XYZ table with torch, MIG welder, hoist |

| Material costs: | $1000-1350 |

See Also

CEB Press Resarch & Development, Controller Design, Hydraulic Design