Modular Stove Fabrication Procedure: Difference between revisions

Jump to navigation

Jump to search

(→Step 0) |

(→Step 2) |

||

| Line 12: | Line 12: | ||

*Cut angle for 2 mitered frames, just like for [[Power Cube 6]]. | *Cut angle for 2 mitered frames, just like for [[Power Cube 6]]. | ||

**Use Ironworker for mitered cuts | **Use Ironworker for mitered cuts: | ||

<html></html> | |||

**Result: corners fit together such that all metal angle form flat planes | |||

===Quality Control=== | |||

*3 corners fit so there is no more than 1/8" space anywhere | |||

*length of members within 1/4" tolerance | |||

<html><iframe width="300" height="225" src="https://www.youtube.com/embed//Ep1vu0szOZ4" frameborder="0" allowfullscreen></iframe></html> | |||

[[Image:Miteredframe.png|300px]] | [[Image:Miteredframe.png|300px]] | ||

Revision as of 23:13, 16 October 2012

BOM

Start with BOM.

Build

Step 1

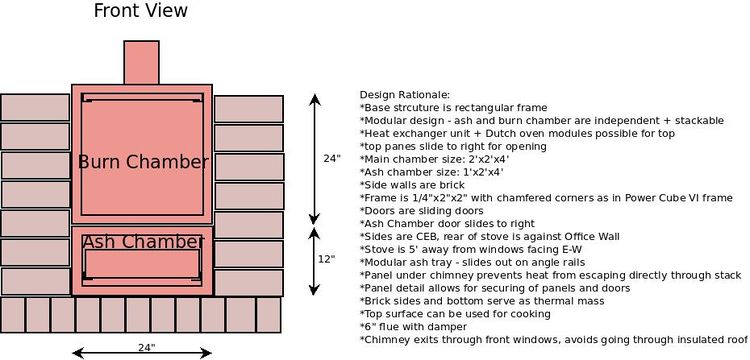

Study Concept: 2 boxes with slideable cover plates clamped down. Ash tray and flame deflector plates side in similar fashion.

Step 2

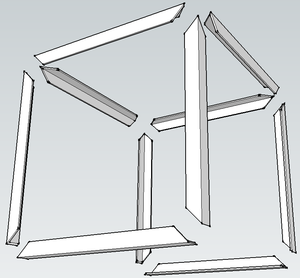

- Cut angle for 2 mitered frames, just like for Power Cube 6.

- Use Ironworker for mitered cuts:

- Result: corners fit together such that all metal angle form flat planes

Quality Control

- 3 corners fit so there is no more than 1/8" space anywhere

- length of members within 1/4" tolerance

Step 3